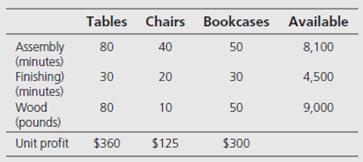

Stickley Furniture is a manufacturer of fine hand-crafted furniture. During the next production period, management is considering producing dining room tables, dining room chairs, and/or

Stickley Furniture is a manufacturer of fine hand-crafted furniture. During the next production period, management is considering producing dining room tables, dining room chairs, and/or bookcases. The time required for each item to go through the two stages of production (assembly and finishing), the amount of wood required (fine cherry wood), and the corresponding unit profits are given in the following table, along with the amount of each resource available in the upcoming production period.

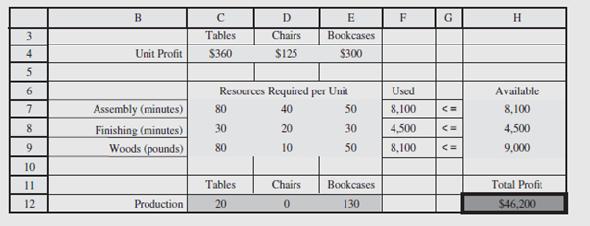

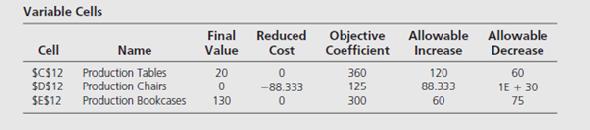

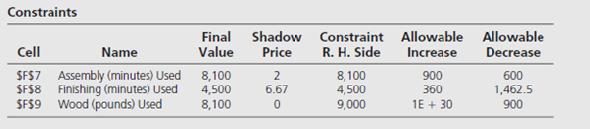

After formulating a linear programming model to determine the production levels that would maximize profit, the solved model and the corresponding sensitivity report are shown below.

a. Suppose the profit per table increases by $100. Will this change the optimal production quantities? What can be said about the change in total profit?

b. Suppose the profit per chair increases by $100. Will this change the optimal production quantities? What can be said about the change in total profit?

c. Suppose the profit per table increases by $90 and the profit per bookcase decreases by $50. Will this change the optimal production quantities? What can be said about the change in total profit?

d. Suppose a worker in the assembly department calls in sick, so eight fewer hours now are available in the assembly department. How much would this affect total profit? Would it change the optimal production quantities?

e. Explain why the shadow price for the wood constraint is zero.

f. A new worker has been hired who is trained to do both assembly and finishing. She will split her time between the two areas, so there now are four additional hours available in both assembly and finishing. How much would this affect total profit? Would this change the optimal production quantities?

g. Based on the sensitivity report, is it wise to have the new worker in part f split her time equally between assembly and finishing, or would some other plan be better?

h. Use a parameter analysis report to determine how the optimal production quantities and total profit will change depending on how the new worker in part f allocates her time between assembly and finishing. In particular, assume 0, 1, 2, . . . , or 8 hours are added to assembly, with a corresponding 8, 7, 6, . . . , or 0 hours added to finishing.

Tables Chairs Bookcases Available Assembly (minutes) 80 40 50 8,100 Finishing) (minutes) Wood 30 20 30 4,500 80 10 50 9,000 (pounds) Unit profit $360 $125 $300

Step by Step Solution

3.42 Rating (155 Votes )

There are 3 Steps involved in it

Step: 1

To address the questions we will analyze the sensitivity report and apply relevant linear programming principles a Profit per Table Increases by 100 O...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started