Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Strength and Modifying Factors: S = Cload size surf temp reliab Recall from the previous presentation: Steel: Unmodified infinite life strength at the endurance

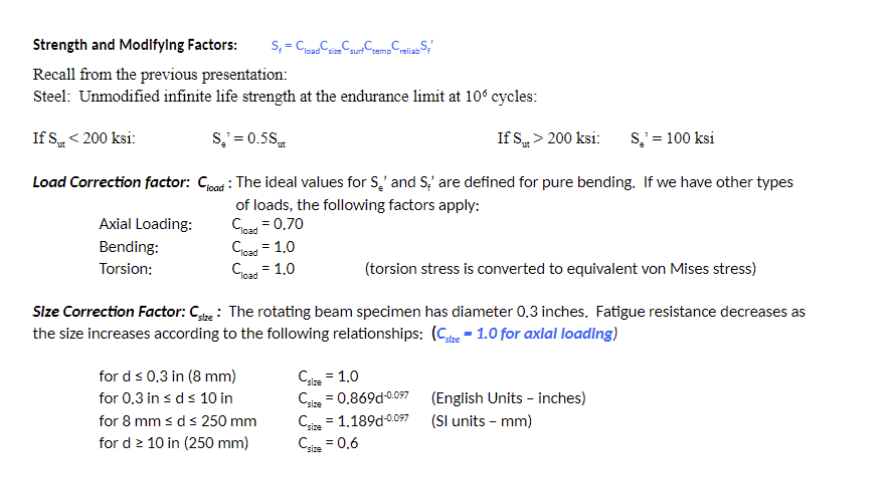

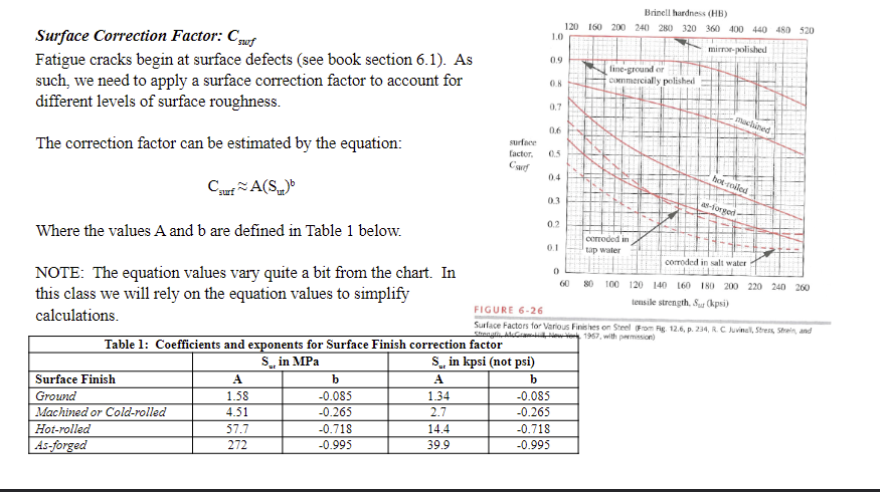

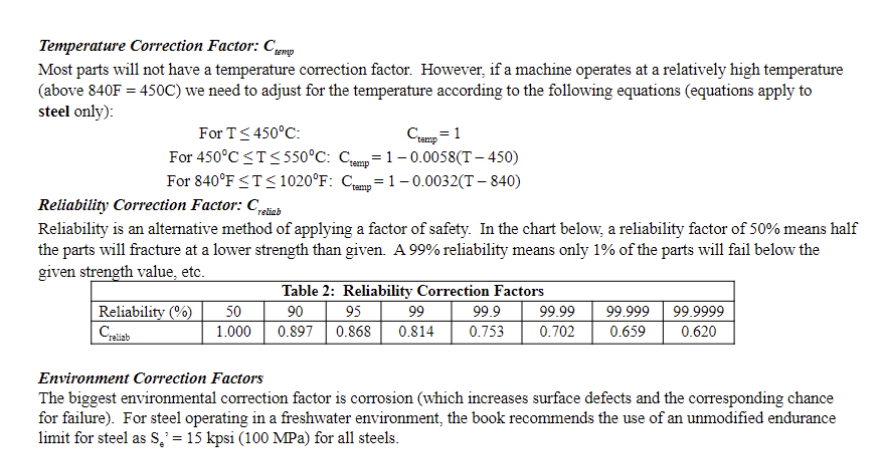

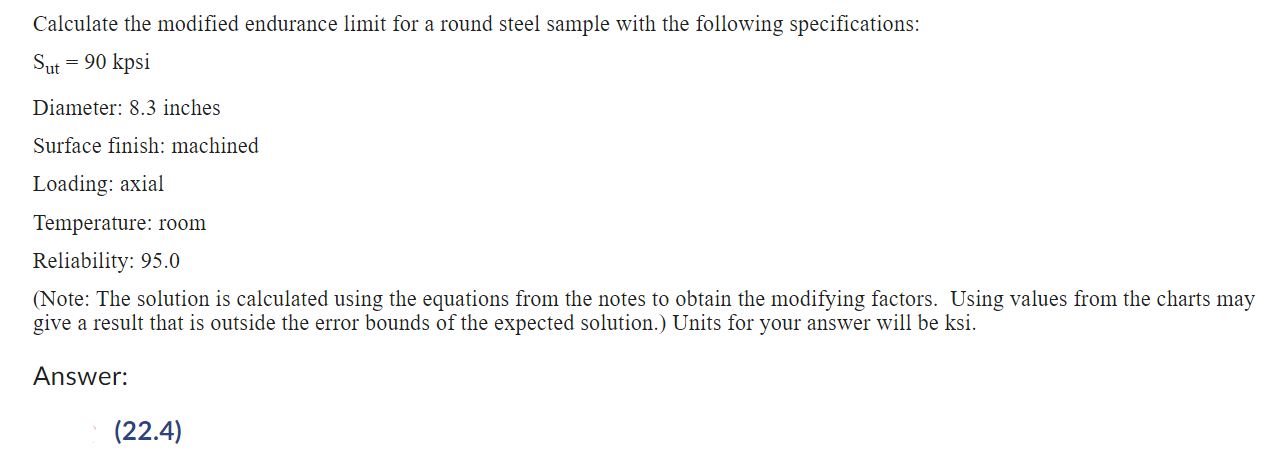

Strength and Modifying Factors: S = Cload size surf temp reliab Recall from the previous presentation: Steel: Unmodified infinite life strength at the endurance limit at 106 cycles: If S 200 ksi: S' = 100 ksi Load Correction factor: Cload: The ideal values for S' and S,' are defined for pure bending. If we have other types of loads, the following factors apply: Axial Loading: Bending: Torsion: Cload = 0.70 Cload = 1.0 Clad = 1.0 (torsion stress is converted to equivalent von Mises stress) Size Correction Factor: Csize: The rotating beam specimen has diameter 0.3 inches. Fatigue resistance decreases as the size increases according to the following relationships: (Csize - 1.0 for axial loading) for d 0,3 in (8 mm) for 0,3 in s d 10 in for 8 mm d 250 mm for d 10 in (250 mm) Csize = 1.0 = Csize 0.869d-0.097 (English Units inches) Csize = 1.189d-0.097 (SI units - mm) Csize = 0.6 Surface Correction Factor: Cof Fatigue cracks begin at surface defects (see book section 6.1). As such, we need to apply a surface correction factor to account for different levels of surface roughness. The correction factor can be estimated by the equation: Car A(S)b Where the values A and b are defined in Table 1 below. NOTE: The equation values vary quite a bit from the chart. In this class we will rely on the equation values to simplify calculations. 1.0 17 0.9 69 0.8 17 0.7 Brinell hardness (HB) 120 160 200 240 280 320 360 400 440 480 520 fine-ground or commercially polished mirror-polished machined hot-roiled as-forged- 0.6 surface factor. 0.5 Caf 0.4 0.3 0.2 0.1 tap water corroded in salt water 0 60 80 100 120 140 160 180 200 220 240 260 tensile strength, Sur (psi) FIGURE 6-26 corroded in Surface Factors for Various Finishes on Steel From Fig. 12.6, p. 234, R. C. Juvina, Stress, Strain, and Table 1: Coefficients and exponents for Surface Finish correction factor Sin MPa Surface Finish Sin kpsi (not psi) A b A b Ground 1.58 -0.085 1.34 -0.085 Machined or Cold-rolled 4.51 -0.265 2.7 -0.265 Hot-rolled 57.7 -0.718 14.4 -0.718 As-forged 272 -0.995 39.9 -0.995 Temperature Correction Factor: Cemp Most parts will not have a temperature correction factor. However, if a machine operates at a relatively high temperature (above 840F = 450C) we need to adjust for the temperature according to the following equations (equations apply to steel only): For T450C: Cramp = 1 For 450C T550C: Ctemp = 1-0.0058(T-450) For 840F T1020F: Camp=1-0.0032(T-840) Reliability Correction Factor: Creliab Reliability is an alternative method of applying a factor of safety. In the chart below, a reliability factor of 50% means half the parts will fracture at a lower strength than given. A 99% reliability means only 1% of the parts will fail below the given strength value, etc. Table 2: Reliability Correction Factors Reliability (%) 50 Creliab 1.000 90 0.897 95 99 0.868 0.814 99.9 0.753 99.99 0.702 99.999 99.9999 0.659 0.620 Environment Correction Factors The biggest environmental correction factor is corrosion (which increases surface defects and the corresponding chance for failure). For steel operating in a freshwater environment, the book recommends the use of an unmodified endurance limit for steel as S = 15 kpsi (100 MPa) for all steels. Calculate the modified endurance limit for a round steel sample with the following specifications: Sut = 90 kpsi Diameter: 8.3 inches Surface finish: machined Loading: axial Temperature: room Reliability: 95.0 (Note: The solution is calculated using the equations from the notes to obtain the modifying factors. Using values from the charts may give a result that is outside the error bounds of the expected solution.) Units for your answer will be ksi. Answer: (22.4)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started