Question

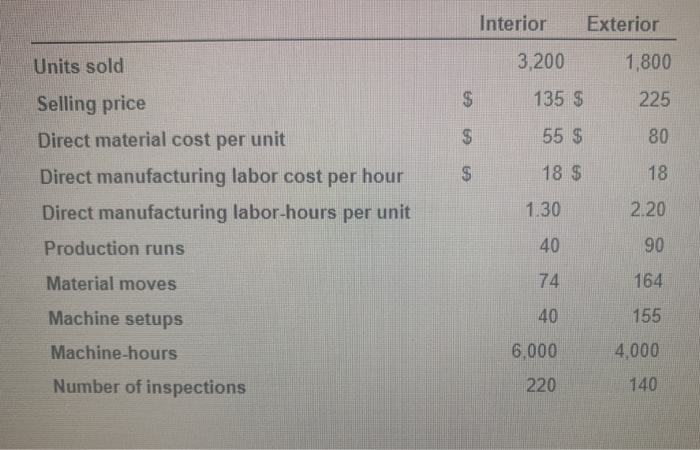

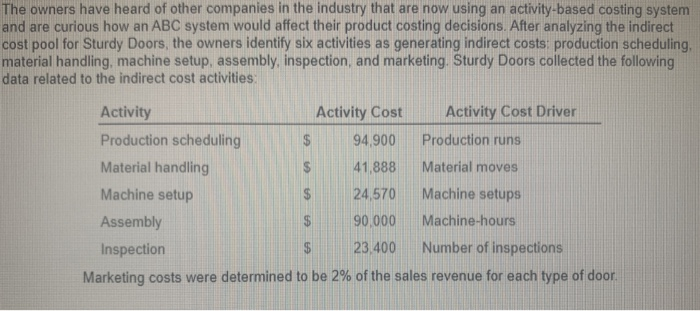

Sturdy Doors, Inc., produces two types of doors, interior and exterior. The company's simple costing system has two direct cost categories (materials and labor) and

Sturdy Doors, Inc., produces two types of doors, interior and exterior. The company's simple costing system has two direct cost categories (materials and labor) and one indirect cost pool. The simple costing system allocates indirect costs on the basis of machine-hours. Recently, the owners of Sturdy Doors have been concerned about a decline in the market share for their interior doors, usually their biggest seller. Information related to Sturdy Doors production for the most recent year follows

Required:

| 1. | Calculate the cost of an interior door and an exterior door under the existing simple costing system. |

| 2. | Calculate the cost of an interior door and an exterior door under an activity-based costing system. |

| 3. | Compare the costs of the doors in requirements 1 and 2. Why do the simple and activity-based costing systems differ in the cost of an interior and exterior door? |

| 4. | How might Sturdy Doors, Inc., use the new cost information from its activity-based costing system to address the declining market share for interior doors? |

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started