Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Subject Name: Systems Simulation and Modelling 3 At a coal-loading facility in the coastal city of Chennai (India), coal is loaded from a main storage

Subject Name: Systems Simulation and Modelling

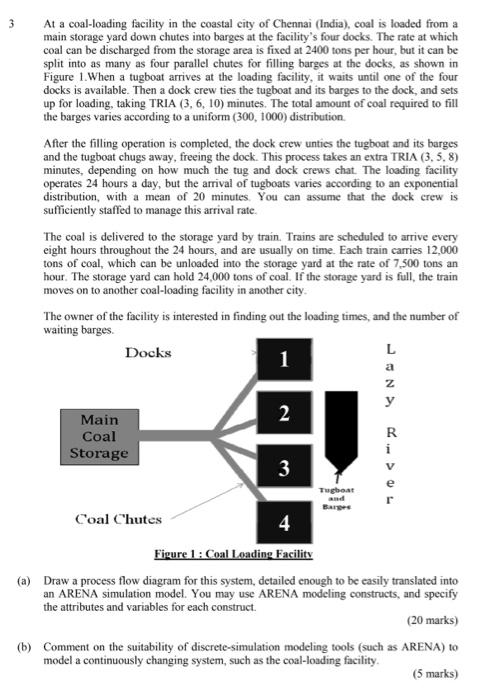

3 At a coal-loading facility in the coastal city of Chennai (India), coal is loaded from a main storage yard down chutes into barges at the facility's four docks. The rate at which coal can be discharged from the storage area is fixed at 2400 tons per hour, but it can be split into as many as four parallel chutes for filling barges at the docks, as shown in Figure 1. When a tugboat arrives at the loading facility, it waits until one of the four docks is available. Then a dock crew ties the tugboat and its barges to the dock, and sets up for loading, taking TRIA (3, 6, 10) minutes. The total amount of coal required to fill the barges varies according to a uniform (300, 1000) distribution After the filling operation is completed, the dock crew unties the tugboat and its barges and the tugboat chugs away, freeing the dock. This process takes an extra TRIA (3. 5.8) minutes, depending on how much the tug and dock crews chat. The loading facility operates 24 hours a day, but the arrival of tugboats varies according to an exponential distribution, with a mean of 20 minutes. You can assume that the dock crew is sufficiently staffed to manage this arrival rate. The coal is delivered to the storage yard by train. Trains are scheduled to arrive every eight hours throughout the 24 hours, and are usually on time. Each train carries 12.000 tons of coal, which can be unloaded into the storage yard at the rate of 7,500 tons an hour. The storage yard can hold 24.000 tons of coal . If the storage yard is full, the train moves on to another coal-loading facility in another city The owner of the facility is interested in finding out the loading times, and the number of waiting barges. Docks L 1 a 1 y 2 Main Coal Storage R i V e 3 Tugbaar Coal Chutes 4 Figure 1 : Coal Loading Facility (a) Draw a process flow diagram for this system, detailed enough to be easily translated into an ARENA simulation model. You may use ARENA modeling constructs, and specify the attributes and variables for each construct (20 marks) (b) Comment on the suitability of discrete-simulation modeling tools (such as ARENA) to model a continuously changing system, such as the coal-loading facility. (5 marks) 3 At a coal-loading facility in the coastal city of Chennai (India), coal is loaded from a main storage yard down chutes into barges at the facility's four docks. The rate at which coal can be discharged from the storage area is fixed at 2400 tons per hour, but it can be split into as many as four parallel chutes for filling barges at the docks, as shown in Figure 1. When a tugboat arrives at the loading facility, it waits until one of the four docks is available. Then a dock crew ties the tugboat and its barges to the dock, and sets up for loading, taking TRIA (3, 6, 10) minutes. The total amount of coal required to fill the barges varies according to a uniform (300, 1000) distribution After the filling operation is completed, the dock crew unties the tugboat and its barges and the tugboat chugs away, freeing the dock. This process takes an extra TRIA (3. 5.8) minutes, depending on how much the tug and dock crews chat. The loading facility operates 24 hours a day, but the arrival of tugboats varies according to an exponential distribution, with a mean of 20 minutes. You can assume that the dock crew is sufficiently staffed to manage this arrival rate. The coal is delivered to the storage yard by train. Trains are scheduled to arrive every eight hours throughout the 24 hours, and are usually on time. Each train carries 12.000 tons of coal, which can be unloaded into the storage yard at the rate of 7,500 tons an hour. The storage yard can hold 24.000 tons of coal . If the storage yard is full, the train moves on to another coal-loading facility in another city The owner of the facility is interested in finding out the loading times, and the number of waiting barges. Docks L 1 a 1 y 2 Main Coal Storage R i V e 3 Tugbaar Coal Chutes 4 Figure 1 : Coal Loading Facility (a) Draw a process flow diagram for this system, detailed enough to be easily translated into an ARENA simulation model. You may use ARENA modeling constructs, and specify the attributes and variables for each construct (20 marks) (b) Comment on the suitability of discrete-simulation modeling tools (such as ARENA) to model a continuously changing system, such as the coal-loading facilityStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started