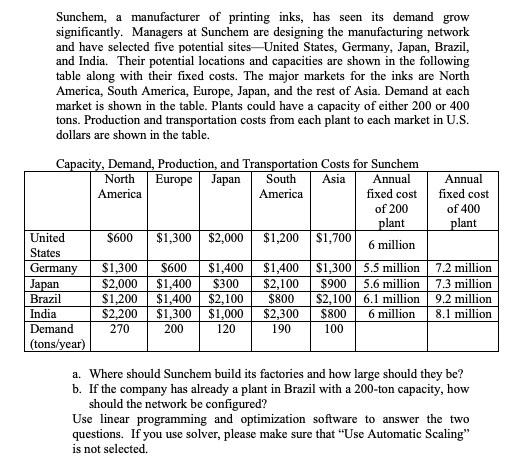

Sunchem, a manufacturer of printing inks, has seen its demand grow significantly. Managers at Sunchem are designing the manufacturing network and have selected five potential sites United States, Germany, Japan, Brazil, and India. Their potential locations and capacities are shown in the following table along with their fixed costs. The major markets for the inks are North America, South America, Europe, Japan, and the rest of Asia. Demand at each market is shown in the table. Plants could have a capacity of either 200 or 400 tons. Production and transportation costs from each plant to each market in U.S. dollars are shown in the table. Capacity, Demand, Production, and Transportation Costs for Sunchem North Europe Japan South Asia Annual Annual America America fixed cost fixed cost of 200 of 400 plant plant United $600 $1,300 $2,000 $1,200 $1,700 6 million States Germany $1,300 $600 $1,400 $1,400 $1,300 5.5 million 7.2 million Japan $2,000 $1,400 $300 $2,100 $900 5.6 million 7.3 million Brazil $1,200 $1,400 $2,100 $800 $2,100 6.1 million 9.2 million India $2,200 $1,300 $1,000 $2,300 $800 6 million 8.1 million Demand 270 200 120 190 100 (tons/year) a. Where should Sunchem build its factories and how large should they be? b. If the company has already a plant in Brazil with a 200-ton capacity, how should the network be configured? Use linear programming and optimization software to answer the two questions. If you use solver, please make sure that "Use Automatic Scaling" is not selected. Sunchem, a manufacturer of printing inks, has seen its demand grow significantly. Managers at Sunchem are designing the manufacturing network and have selected five potential sites United States, Germany, Japan, Brazil, and India. Their potential locations and capacities are shown in the following table along with their fixed costs. The major markets for the inks are North America, South America, Europe, Japan, and the rest of Asia. Demand at each market is shown in the table. Plants could have a capacity of either 200 or 400 tons. Production and transportation costs from each plant to each market in U.S. dollars are shown in the table. Capacity, Demand, Production, and Transportation Costs for Sunchem North Europe Japan South Asia Annual Annual America America fixed cost fixed cost of 200 of 400 plant plant United $600 $1,300 $2,000 $1,200 $1,700 6 million States Germany $1,300 $600 $1,400 $1,400 $1,300 5.5 million 7.2 million Japan $2,000 $1,400 $300 $2,100 $900 5.6 million 7.3 million Brazil $1,200 $1,400 $2,100 $800 $2,100 6.1 million 9.2 million India $2,200 $1,300 $1,000 $2,300 $800 6 million 8.1 million Demand 270 200 120 190 100 (tons/year) a. Where should Sunchem build its factories and how large should they be? b. If the company has already a plant in Brazil with a 200-ton capacity, how should the network be configured? Use linear programming and optimization software to answer the two questions. If you use solver, please make sure that "Use Automatic Scaling" is not selected