Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Super Airtech Corp. manufactures jet engines. They need to plan the fulfillment of orders for the next four months. Due to variances in labor

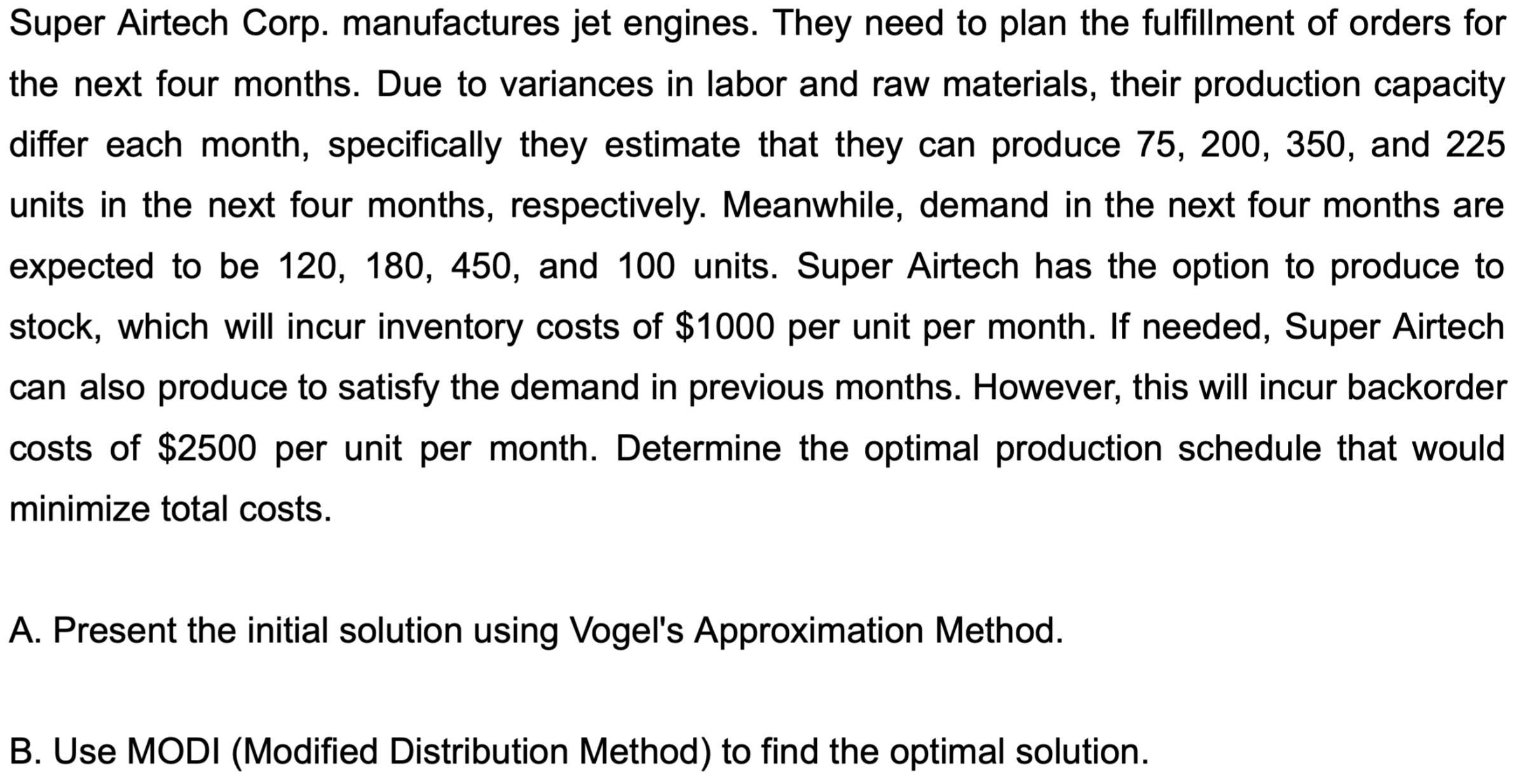

Super Airtech Corp. manufactures jet engines. They need to plan the fulfillment of orders for the next four months. Due to variances in labor and raw materials, their production capacity differ each month, specifically they estimate that they can produce 75, 200, 350, and 225 units in the next four months, respectively. Meanwhile, demand in the next four months are expected to be 120, 180, 450, and 100 units. Super Airtech has the option to produce to stock, which will incur inventory costs of $1000 per unit per month. If needed, Super Airtech can also produce to satisfy the demand in previous months. However, this will incur backorder costs of $2500 per unit per month. Determine the optimal production schedule that would minimize total costs. A. Present the initial solution using Vogel's Approximation Method. B. Use MODI (Modified Distribution Method) to find the optimal solution.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Sure lets solve this using Vogels Approximation Method and then the MODI method Given Data Production Capacities 75 200 350 225 Demand 120 180 450 100 ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started