Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Superpro Software Needs flowchart and gnatt chart Design a fermentation bioreactor that enables cell growth to take place under well-defined operating conditions for the fermentation

Superpro Software

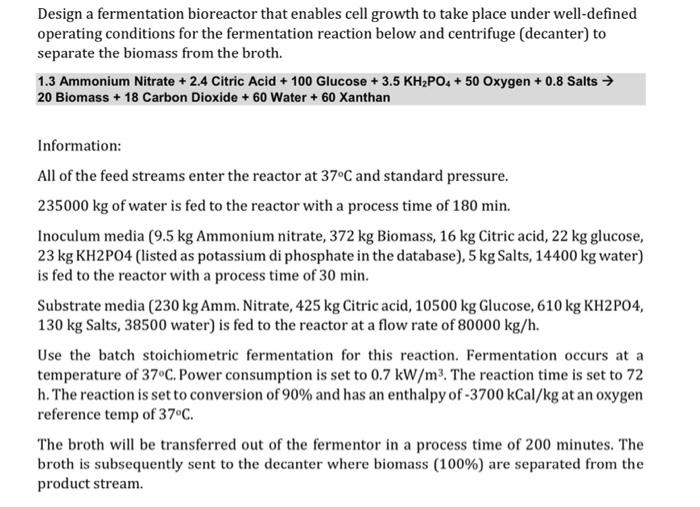

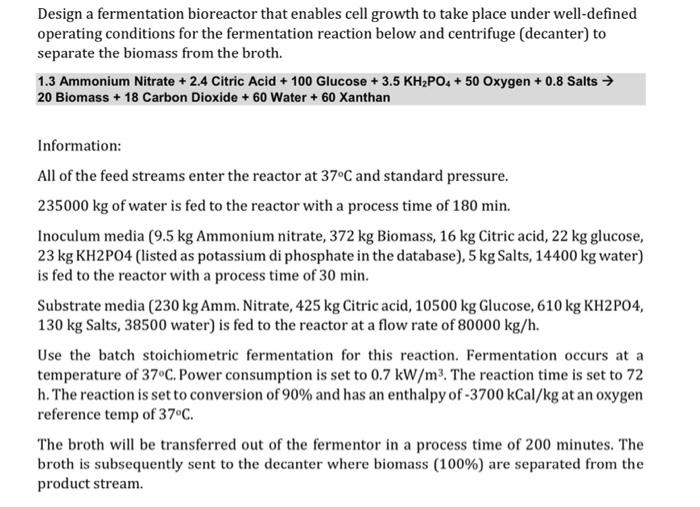

Design a fermentation bioreactor that enables cell growth to take place under well-defined operating conditions for the fermentation reaction below and centrifuge (decanter) to separate the biomass from the broth. 1.3 Ammonium Nitrate + 2.4 Citric Acid + 100 Glucose + 3.5 KH2PO4 + 50 Oxygen + 0.8 Salts 20 Biomass + 18 Carbon Dioxide + 60 Water + 60 Xanthan Information: All of the feed streams enter the reactor at 37C and standard pressure. 235000 kg of water is fed to the reactor with a process time of 180 min. Inoculum media (9.5 kg Ammonium nitrate, 372 kg Biomass, 16 kg Citric acid, 22 kg glucose, 23 kg KH2PO4 (listed as potassium di phosphate in the database), 5 kg Salts, 14400 kg water) is fed to the reactor with a process time of 30 min. Substrate media (230 kg Amm. Nitrate, 425 kg Citric acid, 10500 kg Glucose, 610 kg KH2PO4, 130 kg Salts, 38500 water) is fed to the reactor at a flow rate of 80000 kg/h. Use the batch stoichiometric fermentation for this reaction. Fermentation occurs at a temperature of 37C. Power consumption is set to 0.7 kW/m3. The reaction time is set to 72 h. The reaction is set to conversion of 90% and has an enthalpy of-3700 kcal/kg at an oxygen reference temp of 37C. The broth will be transferred out of the fermentor in a process time of 200 minutes. The broth is subsequently sent to the decanter where biomass (100%) are separated from the product stream Needs flowchart and gnatt chart

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started