Answered step by step

Verified Expert Solution

Question

1 Approved Answer

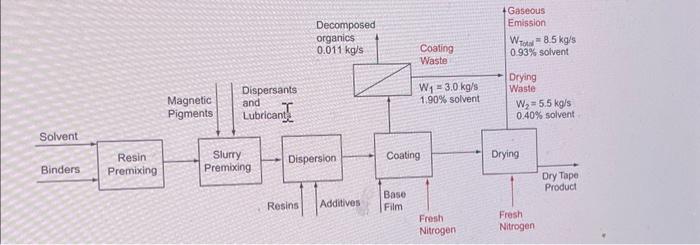

Sustainable Design through process integration subject 1. Consider the magnetic tape manufacturing process shown in Fig. 4.44. A description of the process is given by

Sustainable Design through process integration subject

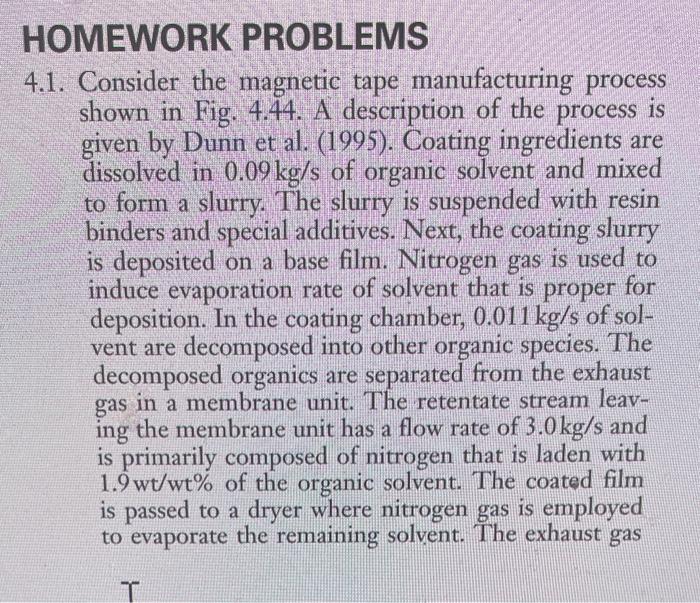

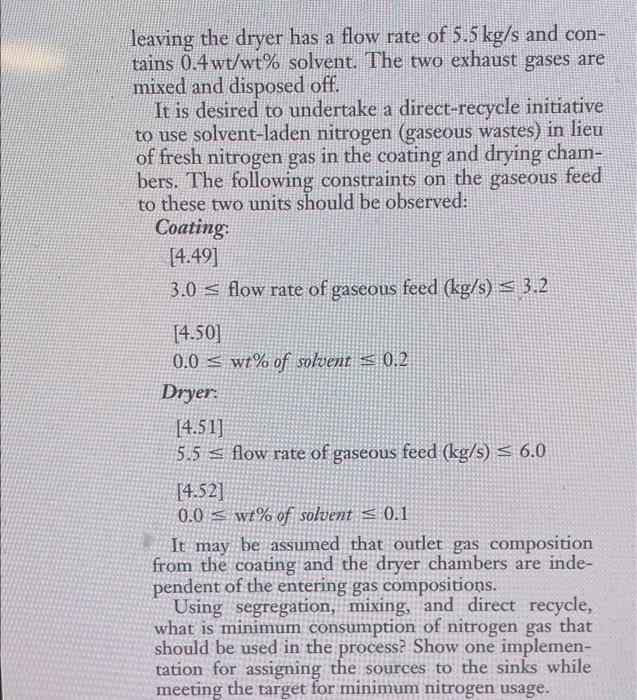

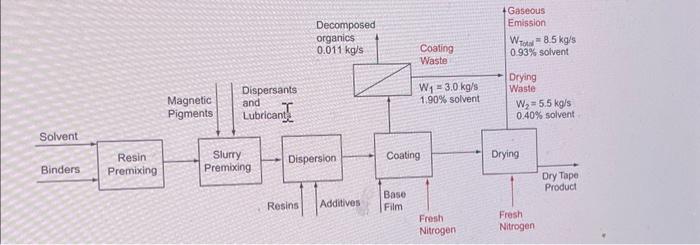

1. Consider the magnetic tape manufacturing process shown in Fig. 4.44. A description of the process is given by Dunn et al. (1995). Coating ingredients are dissolved in 0.09kg/s of organic solvent and mixed to form a slurry. The slurry is suspended with resin binders and special additives. Next, the coating slurry is deposited on a base film. Nitrogen gas is used to induce evaporation rate of solvent that is proper for deposition. In the coating chamber, 0.011kg/s of solvent are decomposed into other organic species. The decomposed organics are separated from the exhaust gas in a membrane unit. The retentate stream leaving the membrane unit has a flow rate of 3.0kg/s and is primarily composed of nitrogen that is laden with 1.9wt/wt% of the organic solvent. The coated film is passed to a dryer where nitrogen gas is employed to evaporate the remaining solvent. The exhaust gas leaving the dryer has a flow rate of 5.5kg/s and con tains 0.4wt/wt% solvent. The two exhaust gases ar mixed and disposed off. It is desired to undertake a direct-recycle initiativ to use solvent-laden nitrogen (gaseous wastes) in liet of fresh nitrogen gas in the coating and drying cham bers. The following constraints on the gaseous feec to these two units should be observed: Coating: [4.49] 3.0 flow rate of gaseous feed (kg/s)3.2 [4.50] 0.0wt% of solvent =0.2 Dryer: [4.51] 5.5 flow rate of gaseous feed (kg/s)6.0 [4.52] 0.0wt% of solvent 0.1 It may be assumed that outlet gas composition from the coating and the dryer chambers are independent of the entering gas compositions. Using segregation, mixing, and direct recycle, what is minimum consumption of nitrogen gas that should be used in the process? Show one implementation for assigning the sources to the sinks while meeting the target for minimum nitrogen usage

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started