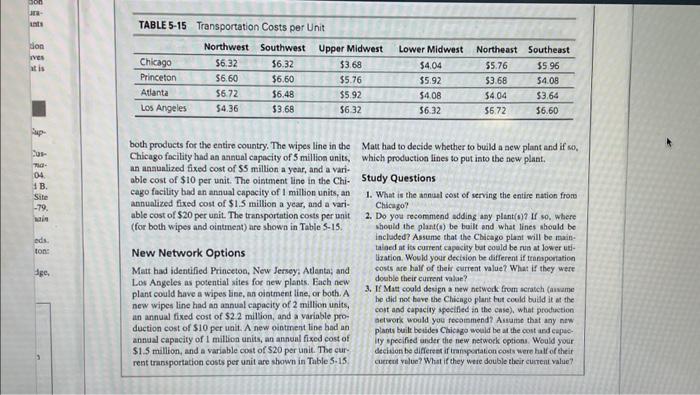

TABLE 5-15 Transportation Costs per Unit boch products for the eatire country. The wipes line in the Malt had to decide whether to build a aew plant and if co, Chicago facility had an annual capocity of 5 million units, which production lines to put iato the new plant. an angunlized fixed cost of 55 million a year, and a variable cost of $10 per unit. The ointment line in the Chi- Study Questions cago facility bad an annual capacity of 1 milion units, an 1. What is the annual sost of serving the entire ration from annualized fixed cost of $1.5 million a year, and a variChicago? able cost of $20 per unit. The transportation costs per unit 2. Do you recommend adding any plant(o)? If so, where (for both wipes and ointment) are shown in Table S-15. should the plant(o) be built and what lines sboold be incladed? Assume that the CMcago plant will be main- New Network Options taiaed at is current capechy but coold be nus at lower utisors are hair of their current value? What if they were Los Angeles as potential sites for new plants. Each new double their current valae? plant could have a wipes liee, an oiatment line, or both. A 3. If Mart coald devign a bew nctwork from serach (aiwame new wipes line had an annual capacity of 2 million units, he did nox tore the Chicngo plant tut coeld bulld it at the an annual fixed cost of $22 miltion, and a variable procort aod capacity speeifled in the cone), what produrtion aetwork would you fesornmend? Asume that any new duction cost of $10 per uait. A new ointment line bod an placts tuilt beides Claicago would be at the cont and cepueannual capacity of 1 million units, an anneal fixed cost of ity specified ander the new netwoek cptions. Would your $1.5 million, and a variable cost of $20 per unit. The curdecision be differest if transportation costs were half of their rent transportation costs per unit are shown in Table 5-15 carrent volue? What if they weie double their cuiteit value? TABLE 5-15 Transportation Costs per Unit boch products for the eatire country. The wipes line in the Malt had to decide whether to build a aew plant and if co, Chicago facility had an annual capocity of 5 million units, which production lines to put iato the new plant. an angunlized fixed cost of 55 million a year, and a variable cost of $10 per unit. The ointment line in the Chi- Study Questions cago facility bad an annual capacity of 1 milion units, an 1. What is the annual sost of serving the entire ration from annualized fixed cost of $1.5 million a year, and a variChicago? able cost of $20 per unit. The transportation costs per unit 2. Do you recommend adding any plant(o)? If so, where (for both wipes and ointment) are shown in Table S-15. should the plant(o) be built and what lines sboold be incladed? Assume that the CMcago plant will be main- New Network Options taiaed at is current capechy but coold be nus at lower utisors are hair of their current value? What if they were Los Angeles as potential sites for new plants. Each new double their current valae? plant could have a wipes liee, an oiatment line, or both. A 3. If Mart coald devign a bew nctwork from serach (aiwame new wipes line had an annual capacity of 2 million units, he did nox tore the Chicngo plant tut coeld bulld it at the an annual fixed cost of $22 miltion, and a variable procort aod capacity speeifled in the cone), what produrtion aetwork would you fesornmend? Asume that any new duction cost of $10 per uait. A new ointment line bod an placts tuilt beides Claicago would be at the cont and cepueannual capacity of 1 million units, an anneal fixed cost of ity specified ander the new netwoek cptions. Would your $1.5 million, and a variable cost of $20 per unit. The curdecision be differest if transportation costs were half of their rent transportation costs per unit are shown in Table 5-15 carrent volue? What if they weie double their cuiteit value