Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The 4 case study questions. question #3 would be most helpful. This is all the info that was provided J&L Packaging, Inc.: Cash-to-Cash Conversion Cycle

The 4 case study questions. question #3 would be most helpful. This is all the info that was provided

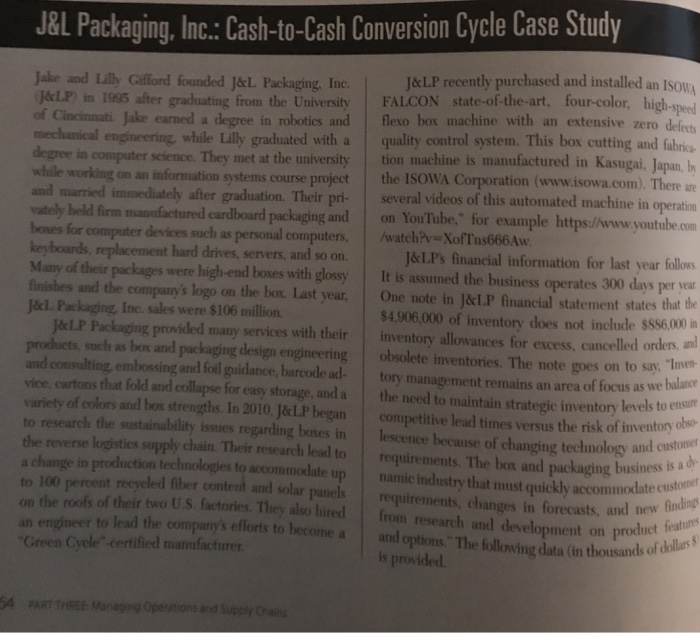

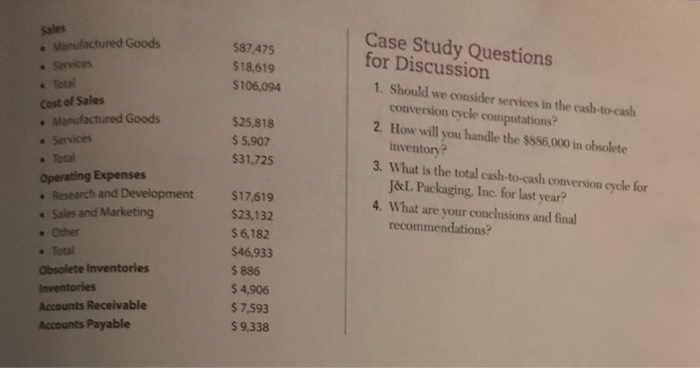

J&L Packaging, Inc.: Cash-to-Cash Conversion Cycle Case Study Jake and Luily Gifford founded J&L Packaging. Inc. J&LP recently purchased and installed an ISOWA jKdL.P) in 1995 after gradhuating from the Univerity FALCON state-of-the-art, four-color, high-sped of Cincinnati. Jake earned a degree in robotics and flexo box machine with an extensive zero dei nechanical engineering, while Lilly graduated with a quality control system. This box cutting and fabria- degree in computer science. They met at the university tion machine is manufactured in Kasugai, Japan, b while working on an information systems course project the lets ISOWA Corporation (www.isowa.com). There a vately held firms manufactured cardboard packaging and on YouTube, for example https:/www.youtube com boses for computer devices such as personal computers, watchPv-XofTns666Aw keyboards, replacement hard drives, servers, and so on. Many of their packages were high-end boses with glossy It is assumed the business operates 300 days per yur inishes and the company's logo on the box. Last year, One note in J&L.P financial statement states that the J&cl. Packaging, Inc sales were $106 million after graduation. Their pri-several videos of this automated machine in operation J&LP's financial information for last year follons $4,906,000 of inventory does not include $$86000 n J&eLP Packaging provided many services with their inventory allowances for excess, cancelled orders, un products, such as box and packaging design engineering obsolete inventories. The note goes on to say. "Imer and consulting embossing and fol guidance, barcode ad- tory management remains an area of focus as we bllacr vice, cartons that fold and collapse for easy storage, and a the need to maintain strategic inventory levels to ensuire variety of colors and box strengths. In 2010, JecL.P began competitive lead times versus the risk of inventory obso to research the sustanability issues regarding boxes in lescence because of changing technology and custoue the reverse logisties supply chain. Their research lead to requirements. The box and packaging business s a change in production technologies to accommodate up namic industry that must quickly accommodates to 100 percent recycled fiber on the roofs of their two U.S. factories. They alsied from research and development on product content and solar pan requirements, changes in forecasts, and new features The folloving data (in thousands of dillin to Green Cyele-certified manufacturer isStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access with AI-Powered Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started