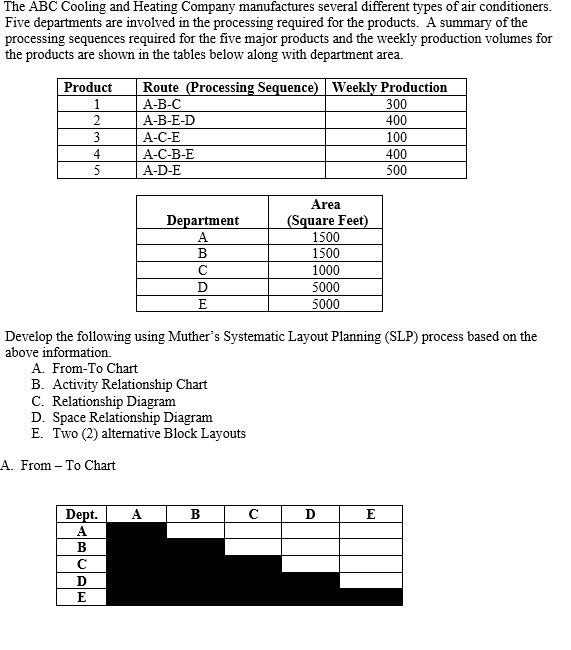

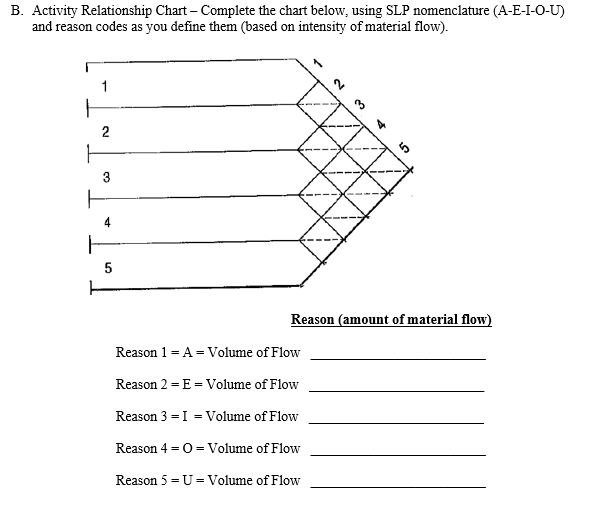

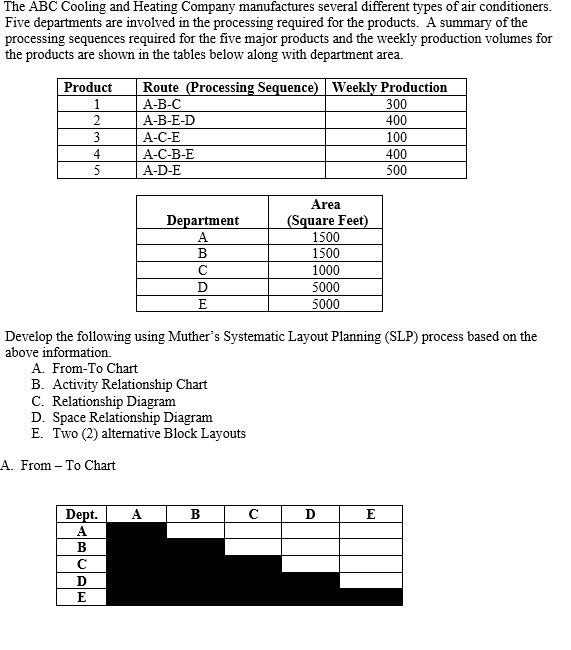

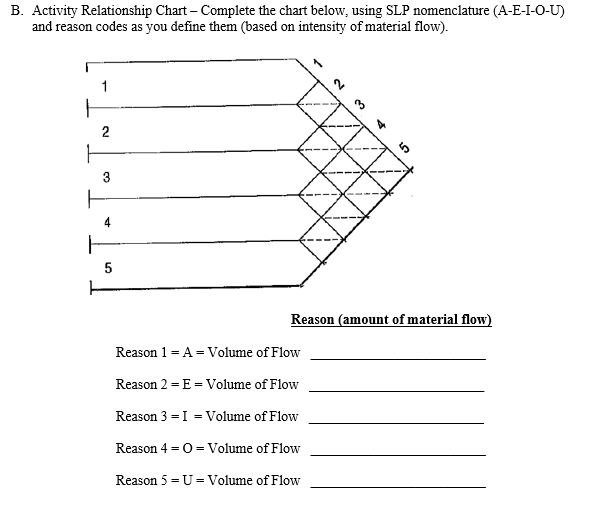

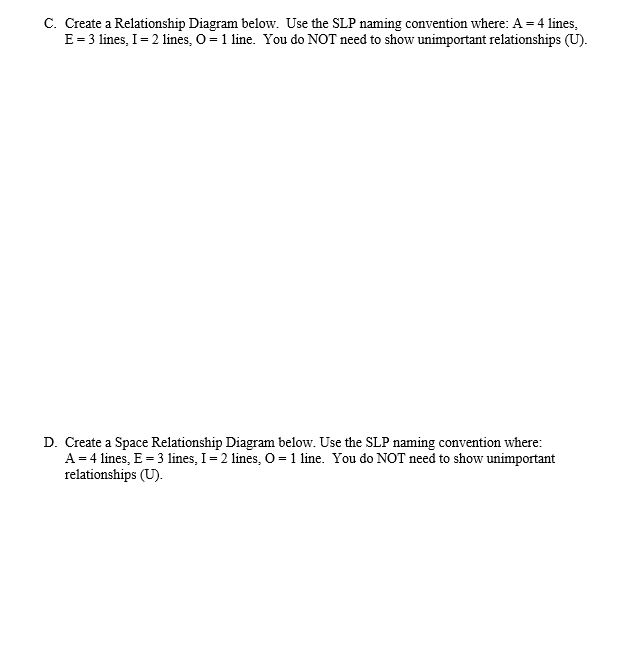

The ABC Cooling and Heating Company manufactures several different types of air conditioners. Five departments are involved in the processing required for the products. A summary of the processing sequences required for the five major products and the weekly production volumes for the products are shown in the tables below along with department area. Product Route (Processing Sequence) | Weekly Production A-B-C 300 A-B-E-D 400 A-C-E 100 A-C-B-E 400 A-D-E 500 Department Area (Square Feet) 1500 1500 1000 5000 5000 D Develop the following using Muther's Systematic Layout Planning (SLP) process based on the above information. A. From-To Chart B. Activity Relationship Chart C. Relationship Diagram D. Space Relationship Diagram E. Two (2) alternative Block Layouts A. From - To Chart Dept. A B C DF B. Activity Relationship Chart - Complete the chart below, using SLP nomenclature (A-E-I-O-U) and reason codes as you define them (based on intensity of material flow). Reason (amount of material flow) Reason 1 = A= Volume of Flow Reason 2 - E = Volume of Flow Reason 3 = I = Volume of Flow Reason 4 - 0 = Volume of Flow Reason 5 - U - Volume of Flow C. Create a Relationship Diagram below. Use the SLP naming convention where: A = 4 lines, E-3 lines, I = 2 lines, 0 - 1 line. You do NOT need to show unimportant relationships (U). D. Create a Space Relationship Diagram below. Use the SLP naming convention where: A = 4 lines, E = 3 lines, I = 2 lines, O = 1 line. You do NOT need to show unimportant relationships (U). The ABC Cooling and Heating Company manufactures several different types of air conditioners. Five departments are involved in the processing required for the products. A summary of the processing sequences required for the five major products and the weekly production volumes for the products are shown in the tables below along with department area. Product Route (Processing Sequence) | Weekly Production A-B-C 300 A-B-E-D 400 A-C-E 100 A-C-B-E 400 A-D-E 500 Department Area (Square Feet) 1500 1500 1000 5000 5000 D Develop the following using Muther's Systematic Layout Planning (SLP) process based on the above information. A. From-To Chart B. Activity Relationship Chart C. Relationship Diagram D. Space Relationship Diagram E. Two (2) alternative Block Layouts A. From - To Chart Dept. A B C DF B. Activity Relationship Chart - Complete the chart below, using SLP nomenclature (A-E-I-O-U) and reason codes as you define them (based on intensity of material flow). Reason (amount of material flow) Reason 1 = A= Volume of Flow Reason 2 - E = Volume of Flow Reason 3 = I = Volume of Flow Reason 4 - 0 = Volume of Flow Reason 5 - U - Volume of Flow C. Create a Relationship Diagram below. Use the SLP naming convention where: A = 4 lines, E-3 lines, I = 2 lines, 0 - 1 line. You do NOT need to show unimportant relationships (U). D. Create a Space Relationship Diagram below. Use the SLP naming convention where: A = 4 lines, E = 3 lines, I = 2 lines, O = 1 line. You do NOT need to show unimportant relationships (U)