Question

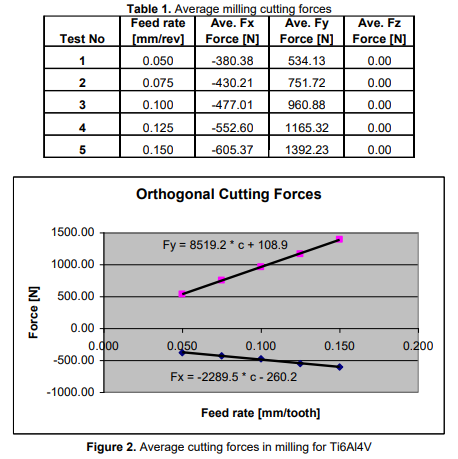

The average cutting forces for different feed rates in Ti6Al4V milling have been measured using table dynamometer (Table 1). During the cutting test a carbide

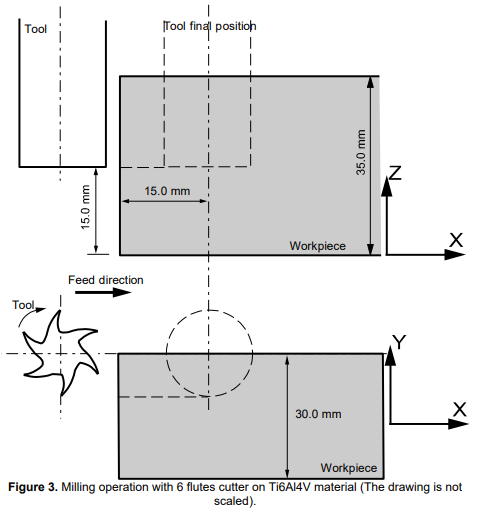

The average cutting forces for different feed rates in Ti6Al4V milling have been measured using table dynamometer (Table 1). During the cutting test a carbide cylindrical end mill with 4 flutes, 0 degree helix angle and 19.05 mm diameter has been used. All the cutting tests have been performed as full immersion (?st=0 degree, ?ex=180 degree) with 5.0 mm depth of cut. a) Find the average mechanistic milling cutting coefficients ( Ktc Krc Kac Kte Kre Kae , , , , , ) using experimental average cutting forces for Ti6Al4V workpiece material (Figure 2). (7 marks)

Tool Tool Tool final position 15.0 mm Feed direction 15.0 mm Workpiece 30.0 mm 35.0 mm Workpiece Figure 3. Milling operation with 6 flutes cutter on Ti6Al4V material (The drawing is not scaled).

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started