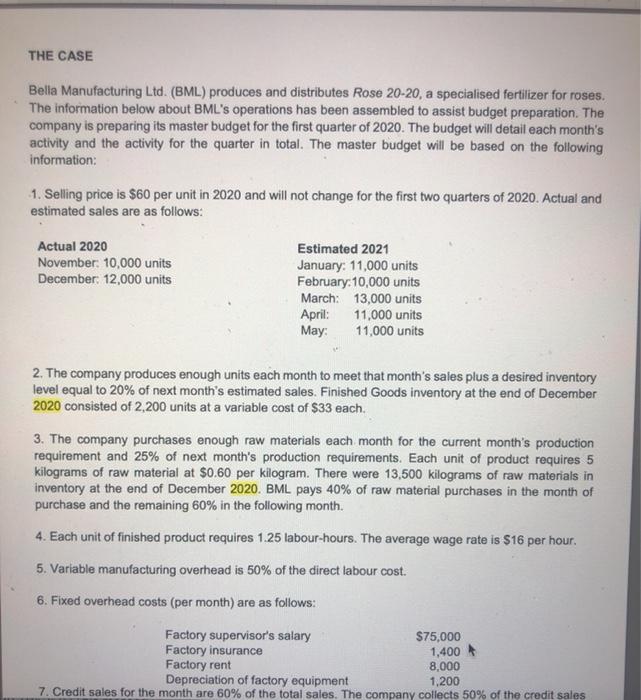

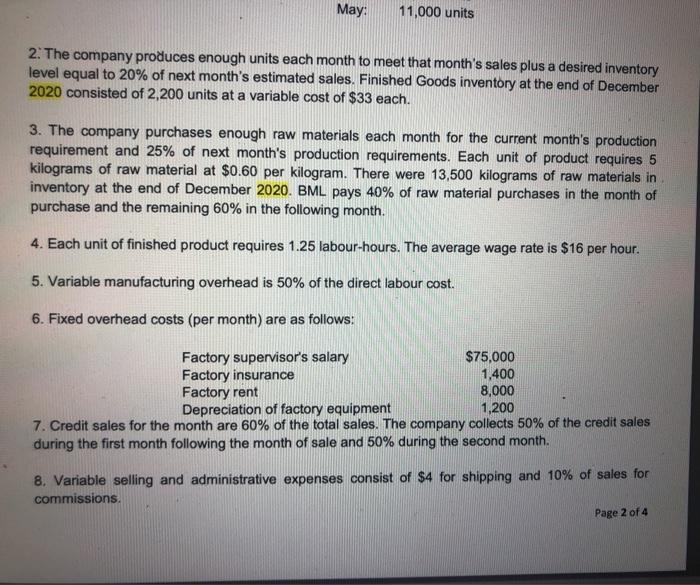

THE CASE Bella Manufacturing Ltd. (BML) produces and distributes Rose 20-20, a specialised fertilizer for roses. The information below about BML's operations has been assembled to assist budget preparation. The company is preparing its master budget for the first quarter of 2020. The budget will detail each month's activity and the activity for the quarter in total. The master budget will be based on the following information: 1. Selling price is $60 per unit in 2020 and will not change for the first two quarters of 2020. Actual and estimated sales are as follows: Actual 2020 November 10,000 units December 12,000 units Estimated 2021 January: 11,000 units February:10,000 units March 13,000 units April: 11,000 units May 11,000 units 2. The company produces enough units each month to meet that month's sales plus a desired inventory level equal to 20% of next month's estimated sales. Finished Goods inventory at the end of December 2020 consisted of 2,200 units at a variable cost of $33 each. 3. The company purchases enough raw materials each month for the current month's production requirement and 25% of next month's production requirements. Each unit of product requires 5 kilograms of raw material at $0.60 per kilogram. There were 13,500 kilograms of raw materials in inventory at the end of December 2020. BML pays 40% of raw material purchases in the month of purchase and the remaining 60% in the following month. 4. Each unit of finished product requires 1.25 labour-hours. The average wage rate is $16 per hour. 5. Variable manufacturing overhead is 50% of the direct labour cost. 6. Fixed overhead costs (per month) are as follows: Factory supervisor's salary $75,000 Factory insurance 1,400 Factory rent 8,000 Depreciation of factory equipment 1,200 7. Credit sales for the month are 60% of the total sales. The company collects 50% of the credit sales May: 11,000 units 2. The company produces enough units each month to meet that month's sales plus a desired inventory level equal to 20% of next month's estimated sales. Finished Goods inventory at the end of December 2020 consisted of 2,200 units at a variable cost of $33 each. 3. The company purchases enough raw materials each month for the current month's production requirement and 25% of next month's production requirements. Each unit of product requires 5 kilograms of raw material at $0.60 per kilogram. There were 13,500 kilograms of raw materials in inventory at the end of December 2020. BML pays 40% of raw material purchases in the month of purchase and the remaining 60% in the following month. 4. Each unit of finished product requires 1.25 labour-hours. The average wage rate is $16 per hour. 5. Variable manufacturing overhead is 50% of the direct labour cost. 6. Fixed overhead costs (per month) are as follows: Factory supervisor's salary $75,000 Factory insurance 1,400 Factory rent 8,000 Depreciation of factory equipment 1,200 7. Credit sales for the month are 60% of the total sales. The company collects 50% of the credit sales during the first month following the month of sale and 50% during the second month. 8. Variable selling and administrative expenses consist of $4 for shipping and 10% of sales for commissions. Page 2 of 4 THE CASE Bella Manufacturing Ltd. (BML) produces and distributes Rose 20-20, a specialised fertilizer for roses. The information below about BML's operations has been assembled to assist budget preparation. The company is preparing its master budget for the first quarter of 2020. The budget will detail each month's activity and the activity for the quarter in total. The master budget will be based on the following information: 1. Selling price is $60 per unit in 2020 and will not change for the first two quarters of 2020. Actual and estimated sales are as follows: Actual 2020 November 10,000 units December 12,000 units Estimated 2021 January: 11,000 units February:10,000 units March 13,000 units April: 11,000 units May 11,000 units 2. The company produces enough units each month to meet that month's sales plus a desired inventory level equal to 20% of next month's estimated sales. Finished Goods inventory at the end of December 2020 consisted of 2,200 units at a variable cost of $33 each. 3. The company purchases enough raw materials each month for the current month's production requirement and 25% of next month's production requirements. Each unit of product requires 5 kilograms of raw material at $0.60 per kilogram. There were 13,500 kilograms of raw materials in inventory at the end of December 2020. BML pays 40% of raw material purchases in the month of purchase and the remaining 60% in the following month. 4. Each unit of finished product requires 1.25 labour-hours. The average wage rate is $16 per hour. 5. Variable manufacturing overhead is 50% of the direct labour cost. 6. Fixed overhead costs (per month) are as follows: Factory supervisor's salary $75,000 Factory insurance 1,400 Factory rent 8,000 Depreciation of factory equipment 1,200 7. Credit sales for the month are 60% of the total sales. The company collects 50% of the credit sales May: 11,000 units 2. The company produces enough units each month to meet that month's sales plus a desired inventory level equal to 20% of next month's estimated sales. Finished Goods inventory at the end of December 2020 consisted of 2,200 units at a variable cost of $33 each. 3. The company purchases enough raw materials each month for the current month's production requirement and 25% of next month's production requirements. Each unit of product requires 5 kilograms of raw material at $0.60 per kilogram. There were 13,500 kilograms of raw materials in inventory at the end of December 2020. BML pays 40% of raw material purchases in the month of purchase and the remaining 60% in the following month. 4. Each unit of finished product requires 1.25 labour-hours. The average wage rate is $16 per hour. 5. Variable manufacturing overhead is 50% of the direct labour cost. 6. Fixed overhead costs (per month) are as follows: Factory supervisor's salary $75,000 Factory insurance 1,400 Factory rent 8,000 Depreciation of factory equipment 1,200 7. Credit sales for the month are 60% of the total sales. The company collects 50% of the credit sales during the first month following the month of sale and 50% during the second month. 8. Variable selling and administrative expenses consist of $4 for shipping and 10% of sales for commissions. Page 2 of 4