Answered step by step

Verified Expert Solution

Question

1 Approved Answer

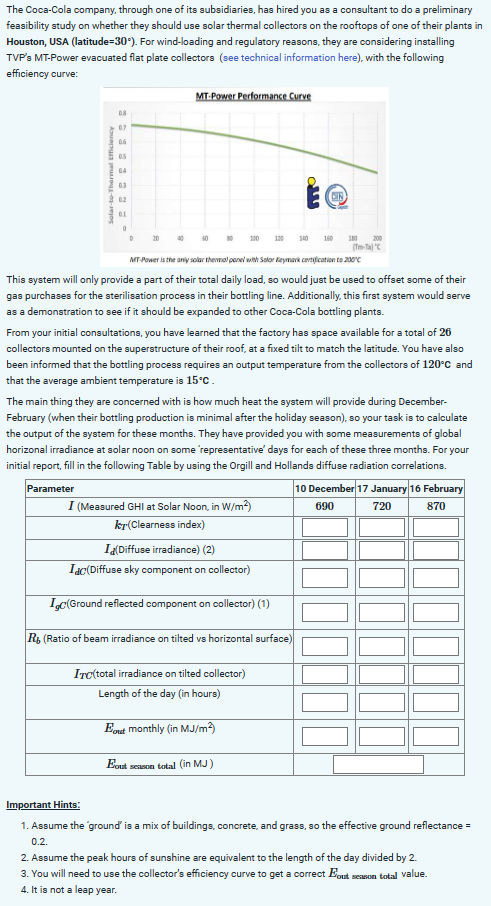

The Coca-Cola company, through one of its subsidiaries, has hired you as a consultant to do a preliminary feasibility study on whether they should

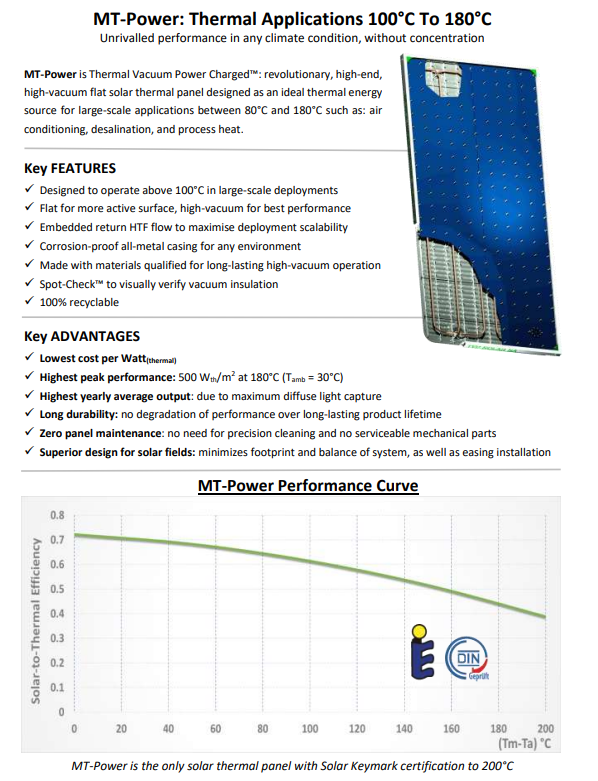

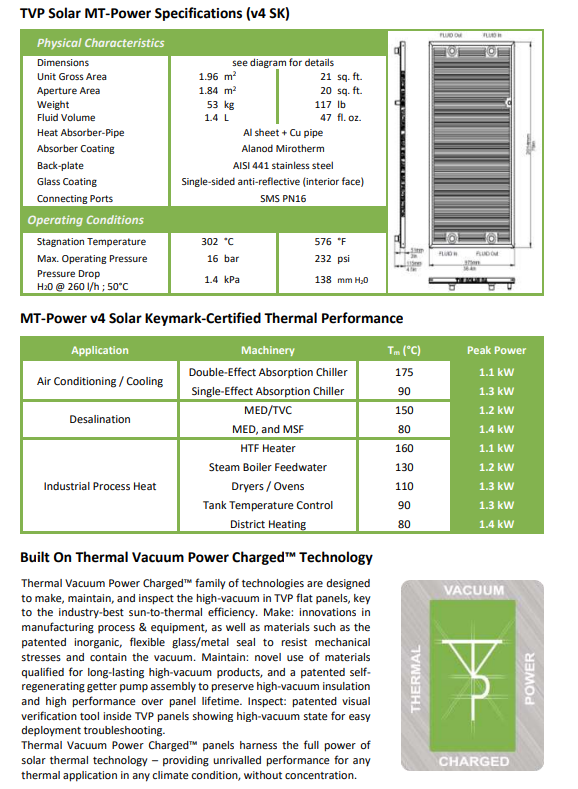

The Coca-Cola company, through one of its subsidiaries, has hired you as a consultant to do a preliminary feasibility study on whether they should use solar thermal collectors on the rooftops of one of their plants in Houston, USA (latitude=30). For wind-loading and regulatory reasons, they are considering installing TVP's MT-Power evacuated flat plate collectors (see technical information here), with the following efficiency curve: Solar-to-Thermal Efficiency 0.8 0.7 0.6 0.5 0.4 03 0.2 01 8 MT-Power Performance Curve 180 200 (Tm-Ta) C MT-Power is the only solar thermal panel with Salor Keymark certification to 200C This system will only provide a part of their total daily load, so would just be used to offset some of their gas purchases for the sterilisation process in their bottling line. Additionally, this first system would serve as a demonstration to see if it should be expanded to other Coca-Cola bottling plants. 140 160 From your initial consultations, you have learned that the factory has space available for a total of 26 collectors mounted on the superstructure of their roof, at a fixed tilt to match the latitude. You have also been informed that the bottling process requires an output temperature from the collectors of 120C and that the average ambient temperature is 15C. Id(Diffuse irradiance) (2) Iac(Diffuse sky component on collector) Igc(Ground reflected component on collector) (1) R (Ratio of beam irradiance on tilted vs horizontal surface) ITC(total irradiance on tilted collector) Length of the day (in hours) Eout monthly (in MJ/m) The main thing they are concerned with is how much heat the system will provide during December- February (when their bottling production is minimal after the holiday season), so your task is to calculate the output of the system for these months. They have provided you with some measurements of global horizonal irradiance at solar noon on some 'representative' days for each of these three months. For your initial report, fill in the following Table by using the Orgill and Hollands diffuse radiation correlations. Parameter I (Measured GHI at Solar Noon, in W/m) ky-(Clearness index) Eout season total (in MJ) 10 December 17 January 16 February 690 720 870 Important Hints: 1. Assume the ground' is a mix of buildings, concrete, and grass, so the effective ground reflectance = 0.2. 2. Assume the peak hours of sunshine are equivalent to the length of the day divided by 2. 3. You will need to use the collector's efficiency curve to get a correct Eout season total value. 4. It is not a leap year. MT-Power is Thermal Vacuum Power Charged: revolutionary, high-end, high-vacuum flat solar thermal panel designed as an ideal thermal energy source for large-scale applications between 80C and 180C such as: air conditioning, desalination, and process heat. Key FEATURES Designed to operate above 100C in large-scale deployments Flat for more active surface, high-vacuum for best performance Embedded return HTF flow to maximise deployment scalability Corrosion-proof all-metal casing for any environment Made with materials qualified for long-lasting high-vacuum operation Spot-Check to visually verify vacuum insulation 100% recyclable Key ADVANTAGES Lowest cost per Watt (thermal) Highest peak performance: 500 Wth/m at 180C (Tamb = 30C) Highest yearly average output: due to maximum diffuse light capture Long durability: no degradation of performance over long-lasting product lifetime Zero panel maintenance: no need for precision cleaning and no serviceable mechanical parts Superior design for solar fields: minimizes footprint and balance of system, as well as easing installation MT-Power Performance Curve Solar-to-Thermal Efficiency MT-Power: Thermal Applications 100C To 180C Unrivalled performance in any climate condition, without concentration 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 20 40 60 80 100 120 140 DIN 160 Geprft 200 (Tm-Ta) C MT-Power is the only solar thermal panel with Solar Keymark certification to 200C 180 TVP Solar MT-Power Specifications (v4 SK) Physical Characteristics Dimensions Unit Gross Area Aperture Area Weight Fluid Volume Heat Absorber-Pipe Absorber Coating Back-plate Glass Coating Connecting Ports Operating Conditions Stagnation Temperature Max. Operating Pressure Pressure Drop H0 @ 260 l/h; 50C Desalination see diagram for details Industrial Process Heat 1.96 m 1.84 m 53 kg 1.4 L 302 C 21 sq. ft. 20 sq. ft. 16 bar 1.4 kPa 117 lb 47 fl. oz. AISI 441 stainless steel Single-sided anti-reflective (interior face) SMS PN16 Al sheet + Cu pipe Alanod Mirotherm MT-Power v4 Solar Keymark-Certified Thermal Performance Application Air Conditioning / Cooling 576 F 232 psi 138 mm H0 Machinery Double-Effect Absorption Chiller Single-Effect Absorption Chiller MED/TVC MED, and MSF HTF Heater Steam Boiler Feedwater Dryers / Ovens Tank Temperature Control District Heating Built On Thermal Vacuum Power Charged Technology Thermal Vacuum Power Charged family of technologies are designed to make, maintain, and inspect the high-vacuum in TVP flat panels, key to the industry-best sun-to-thermal efficiency. Make: innovations in manufacturing process & equipment, as well as materials such as the patented inorganic, flexible glass/metal seal to resist mechanical stresses and contain the vacuum. Maintain: novel use of materials qualified for long-lasting high-vacuum products, and a patented self- regenerating getter pump assembly to preserve high-vacuum insulation and high performance over panel lifetime. Inspect: patented visual verification tool inside TVP panels showing high-vacuum state for easy deployment troubleshooting. Thermal Vacuum Power Charged panels harness the full power of solar thermal technology - providing unrivalled performance for any thermal application in any climate condition, without concentration. Tm (C) 175 90 150 80 160 130 110 90 80 THERMAL FLUADO PLUD FLUO FLUDOM Peak Power 1.1 kW 1.3 kW 1.2 kW 1.4 kW 1.1 kW 1.2 kW 1.3 kW 1.3 kW 1.4 kW VACUUM CHARGED POWER

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started