Question

A company manufactures various electrical devices which are sold across the country. We want to establish the manufacturing program for a certain device for the

A company manufactures various electrical devices which are sold across the country.

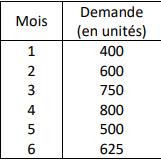

We want to establish the manufacturing program for a certain device for the next 6

month. The sales department estimated that demand for the next 6 months

would be as follows:

The production department can manufacture this device on two shifts:

regular and additional. The maximum regular shift production rate is 20

units and 8 additional units on an additional shift for one day.

The production days are 21 days / month for each of the first 4 months. The

Last 2 months each have 20 production days.

Manufacturing costs are $ 20 per unit in regular shift and $ 35 per unit in shift

additional. The cost of storage, per unit per period (calculated on the stock at the end

period) is $ 15. The initial stock is 450 units and we want a final stock of

200 units at the end of the sixth month.

We want to formulate the linear programming model that would allow a

production scheduling at the lowest cost.

Note that, in order to meet the demands each month, the stock must be at the start

of one month plus the production during the same month must be greater than or equal to the

request this month.

Note also that the stock at the end of a month corresponds to the stock at the beginning of the month, plus the

production during the month, minus the demand for the month.

Answer questions a) to d) using the following variables:

X1 = number of units to be produced during month 1, in regular shift

Y1 = number of units to be produced during month 1, in additional shifts

X2 = number of units to be produced during month 2, in regular shift

Y2 = number of units to be produced in month 2, in additional shifts

X3 = number of units to be produced during month 3, in regular shift

Y3 = number of units to be produced in month 3, in additional shifts

X4 = number of units to be produced during month 4, in regular shift

Y4 = number of units to be produced in month 4, in additional shifts

X5 = number of units to be produced during month 5, in regular shift

Y5 = number of units to be produced in month 5, in additional shifts

X6 = number of units to be produced during month 6, in regular shift

Y6 = number of units to be produced during month 6, in additional shifts

questions:

a) Write the 6 constraints concerning the demand for each month.

b) Write the 12 constraints on the production capacities of each month.

c) Write the constraint on the stock at the end of the sixth month.

d) Write the economic function to be minimized.

Step by Step Solution

3.47 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

a Initial stock 450 Production in the first month X1 Y1 Stock after the first month 450 X1 Y1 This stock must be enough to meet the demand of the first month 400 450 X1 Y1 400 50 X1 Y1 0 i Now after m...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started