Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The company you work for has decided to enter the formaldehyde market. It has asked a design team, which includes you, to come up

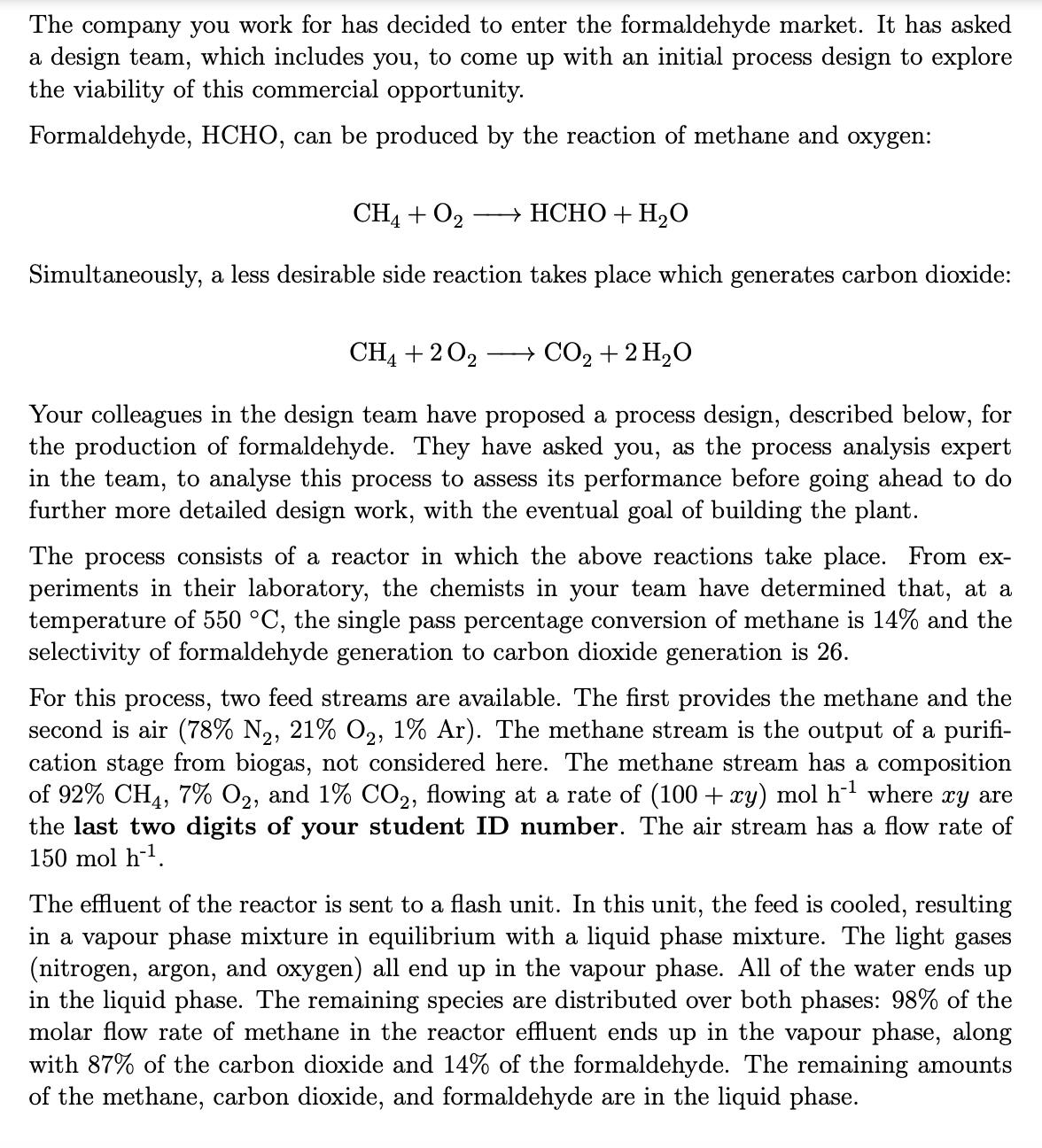

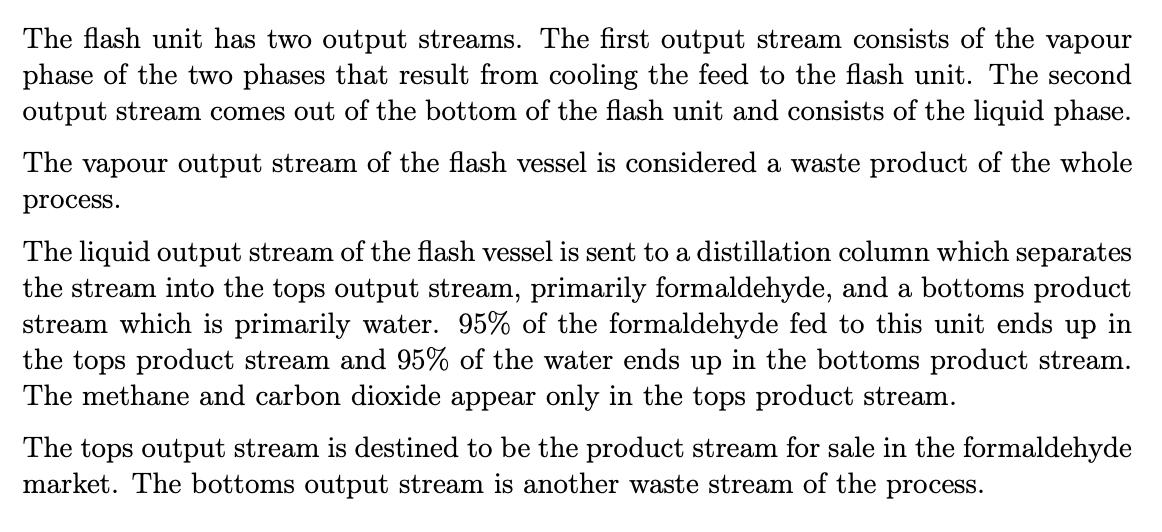

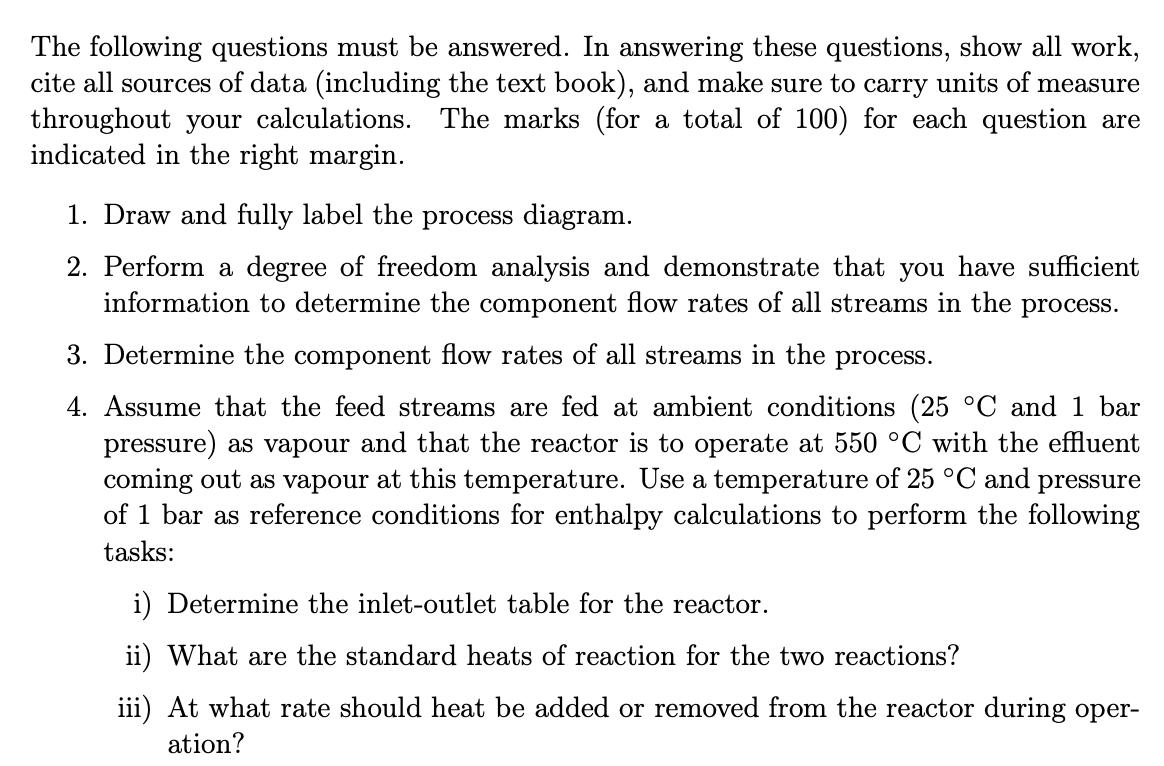

The company you work for has decided to enter the formaldehyde market. It has asked a design team, which includes you, to come up with an initial process design to explore the viability of this commercial opportunity. Formaldehyde, HCHO, can be produced by the reaction of methane and oxygen: CH4 + O HCHO + HO Simultaneously, a less desirable side reaction takes place which generates carbon dioxide: CH4 +202 CO + 2HO Your colleagues in the design team have proposed a process design, described below, for the production of formaldehyde. They have asked you, as the process analysis expert in the team, to analyse this process to assess its performance before going ahead to do further more detailed design work, with the eventual goal of building the plant. The process consists of a reactor in which the above reactions take place. From ex- periments in their laboratory, the chemists in your team have determined that, at a temperature of 550 C, the single pass percentage conversion of methane is 14% and the selectivity of formaldehyde generation to carbon dioxide generation is 26. For this process, two feed streams are available. The first provides the methane and the second is air (78% N, 21% O2, 1% Ar). The methane stream is the output of a purifi- cation stage from biogas, not considered here. The methane stream has a composition of 92% CH4, 7% O2, and 1% CO2, flowing at a rate of (100+ xy) mol h- where xy are the last two digits of your student ID number. The air stream has a flow rate of 150 mol h-. The effluent of the reactor is sent to a flash unit. In this unit, the feed is cooled, resulting in a vapour phase mixture in equilibrium with a liquid phase mixture. The light gases (nitrogen, argon, and oxygen) all end up in the vapour phase. All of the water ends up in the liquid phase. The remaining species are distributed over both phases: 98% of the molar flow rate of methane in the reactor effluent ends up in the vapour phase, along with 87% of the carbon dioxide and 14% of the formaldehyde. The remaining amounts of the methane, carbon dioxide, and formaldehyde are in the liquid phase. The flash unit has two output streams. The first output stream consists of the vapour phase of the two phases that result from cooling the feed to the flash unit. The second output stream comes out of the bottom of the flash unit and consists of the liquid phase. The vapour output stream of the flash vessel is considered a waste product of the whole process. The liquid output stream of the flash vessel is sent to a distillation column which separates the stream into the tops output stream, primarily formaldehyde, and a bottoms product stream which is primarily water. 95% of the formaldehyde fed to this unit ends up in the tops product stream and 95% of the water ends up in the bottoms product stream. The methane and carbon dioxide appear only in the tops product stream. The tops output stream is destined to be the product stream for sale in the formaldehyde market. The bottoms output stream is another waste stream of the process. The following questions must be answered. In answering these questions, show all work, cite all sources of data (including the text book), and make sure to carry units of measure throughout your calculations. The marks (for a total of 100) for each question are indicated in the right margin. 1. Draw and fully label the process diagram. 2. Perform a degree of freedom analysis and demonstrate that you have sufficient information to determine the component flow rates of all streams in the process. 3. Determine the component flow rates of all streams in the process. 4. Assume that the feed streams are fed at ambient conditions (25 C and 1 bar pressure) as vapour and that the reactor is to operate at 550 C with the effluent coming out as vapour at this temperature. Use a temperature of 25 C and pressure of 1 bar as reference conditions for enthalpy calculations to perform the following tasks: i) Determine the inlet-outlet table for the reactor. ii) What are the standard heats of reaction for the two reactions? iii) At what rate should heat be added or removed from the reactor during oper- ation?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Solutions feed rate of methanol 10 moleshr As per the stoichiometry of the reaction CH3OH05O2 HCHOH2O 1 1 mole of methanol consumed 05 moles of O2 and ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started