Question

The companys goal is to minimize the total cost for the next three months. The total cost includes purchasing cost, shipping cost, and inventory cost.

The companys goal is to minimize the total cost for the next three months. The total cost includes purchasing cost, shipping cost, and inventory cost. Your group was hired by the company to help them achieve their goal. They asked you to help them minimize their cost by making optimal decisions on the quantity and timing for shipments ordering from each brand. Based on the optimal solution, the company want your team to answer these specific questions:

What is the total overall cost?

What is the total shipping cost?

What is the total inventory cost?

What should be the number of containers shipped each month from each country and how many tires from each brand should be shipped each month?

What is the number of tires from each brand that will be stored at the warehouse each month?

If the company decided to fix the number of shipments from each country at each month at the current optimal numbers, what will be the additional cost for the company if the demand of Goodyear tires increased in month 3 from 900 to 1000? What will be the additional cost if the demand of Yokohama tires, instead of Goodyear tires, increased in month 3 by 100? (Hint: This question can be answered from the sensitivity report in Excel solver. Please read the steps of generation of sensitivity analysis report in the first page for more details)

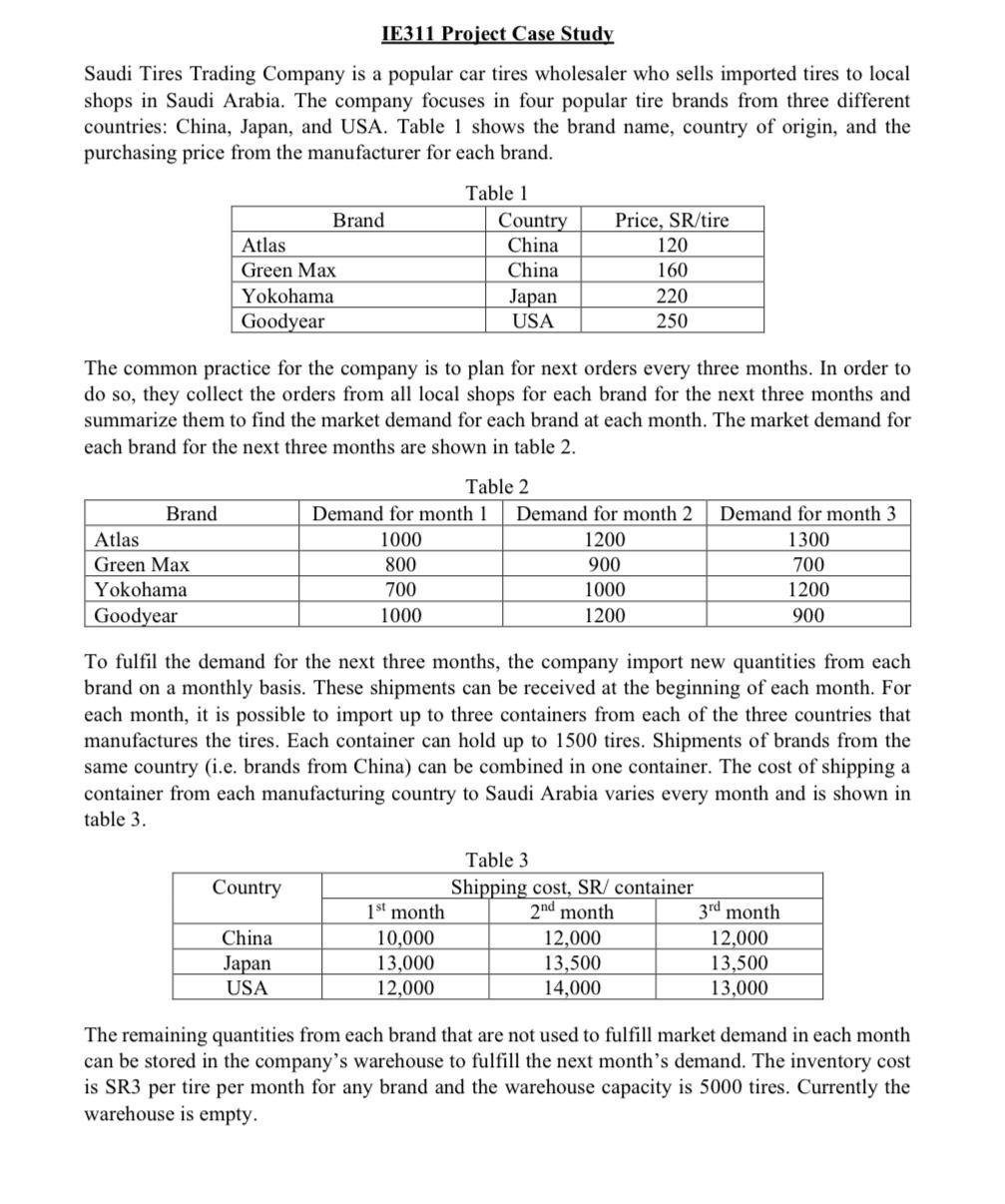

IE311 Project Case Study Saudi Tires Trading Company is a popular car tires wholesaler who sells imported tires to local shops in Saudi Arabia. The company focuses in four popular tire brands from three different countries: China, Japan, and USA. Table 1 shows the brand name, country of origin, and the purchasing price from the manufacturer for each brand. Brand Atlas Green Max Yokohama Goodyear Table 1 Country China China Japan USA Price, SR/tire 120 160 220 250 The common practice for the company is to plan for next orders every three months. In order to do so, they collect the orders from all local shops for each brand for the next three months and summarize them to find the market demand for each brand at each month. The market demand for each brand for the next three months are shown in table 2. Brand Atlas Green Max Yokohama Goodyear Table 2 Demand for month 1 Demand for month 2 1000 1200 800 900 700 1000 1000 1200 Demand for month 3 1300 700 1200 900 To fulfil the demand for the next three months, the company import new quantities from each brand on a monthly basis. These shipments can be received at the beginning of each month. For each month, it is possible to import up to three containers from each of the three countries that manufactures the tires. Each container can hold up to 1500 tires. Shipments of brands from the same country (i.e. brands from China) can be combined in one container. The cost of shipping a container from each manufacturing country to Saudi Arabia varies every month and is shown in table 3. Country Table 3 Shipping cost, SR/ container 1st month 2nd month 3rd month 10,000 12,000 12,000 13,000 13,500 13,500 12.000 14,000 13,000 China Japan USA The remaining quantities from each brand that are not used to fulfill market demand in each month can be stored in the company's warehouse to fulfill the next month's demand. The inventory cost is SR3 per tire per month for any brand and the warehouse capacity is 5000 tires. Currently the warehouse is empty. IE311 Project Case Study Saudi Tires Trading Company is a popular car tires wholesaler who sells imported tires to local shops in Saudi Arabia. The company focuses in four popular tire brands from three different countries: China, Japan, and USA. Table 1 shows the brand name, country of origin, and the purchasing price from the manufacturer for each brand. Brand Atlas Green Max Yokohama Goodyear Table 1 Country China China Japan USA Price, SR/tire 120 160 220 250 The common practice for the company is to plan for next orders every three months. In order to do so, they collect the orders from all local shops for each brand for the next three months and summarize them to find the market demand for each brand at each month. The market demand for each brand for the next three months are shown in table 2. Brand Atlas Green Max Yokohama Goodyear Table 2 Demand for month 1 Demand for month 2 1000 1200 800 900 700 1000 1000 1200 Demand for month 3 1300 700 1200 900 To fulfil the demand for the next three months, the company import new quantities from each brand on a monthly basis. These shipments can be received at the beginning of each month. For each month, it is possible to import up to three containers from each of the three countries that manufactures the tires. Each container can hold up to 1500 tires. Shipments of brands from the same country (i.e. brands from China) can be combined in one container. The cost of shipping a container from each manufacturing country to Saudi Arabia varies every month and is shown in table 3. Country Table 3 Shipping cost, SR/ container 1st month 2nd month 3rd month 10,000 12,000 12,000 13,000 13,500 13,500 12.000 14,000 13,000 China Japan USA The remaining quantities from each brand that are not used to fulfill market demand in each month can be stored in the company's warehouse to fulfill the next month's demand. The inventory cost is SR3 per tire per month for any brand and the warehouse capacity is 5000 tires. Currently the warehouse is emptyStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started