Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The demand for a product is 1000 units per day. The external setup for a punch press is approximately 1.75 hours. The internal setup

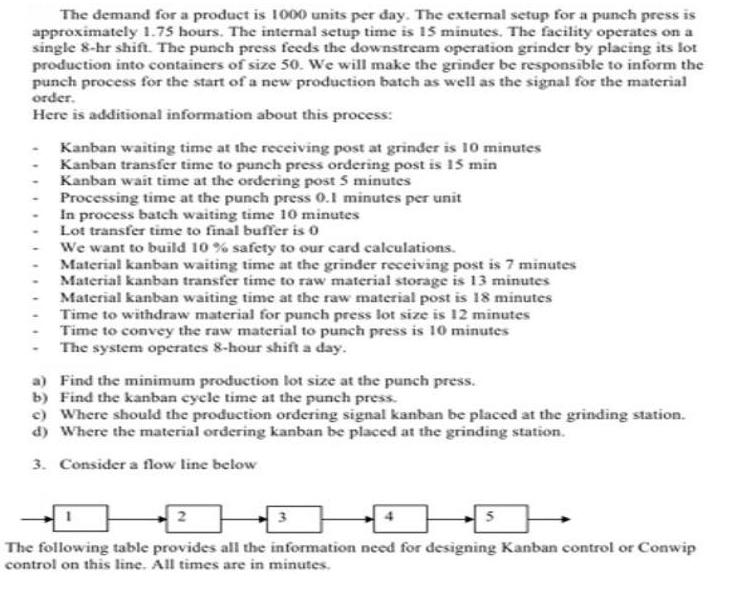

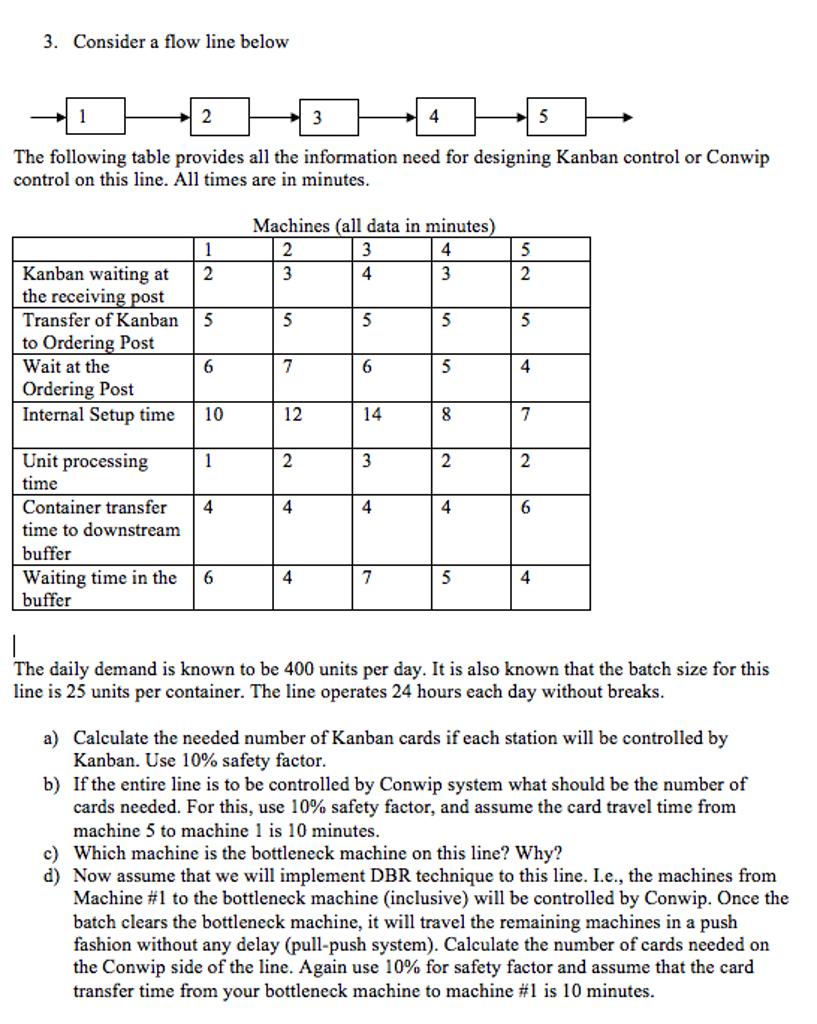

The demand for a product is 1000 units per day. The external setup for a punch press is approximately 1.75 hours. The internal setup time is 15 minutes. The facility operates on a single 8-hr shift. The punch press feeds the downstream operation grinder by placing its lot production into containers of size 50. We will make the grinder be responsible to inform the punch process for the start of a new production batch as well as the signal for the material order. Here is additional information about this process: Kanban waiting time at the receiving post at grinder is 10 minutes Kanban transfer time to punch press ordering post is 15 min Kanban wait time at the ordering post 5 minutes Processing time at the punch press 0.1 minutes per unit In process batch waiting time 10 minutes Lot transfer time to final buffer is 0 We want to build 10% safety to our card calculations. Material kanban waiting time at the grinder receiving post is 7 minutes Material kanban transfer time to raw material storage is 13 minutes Material kanban waiting time at the raw material post is 18 minutes Time to withdraw material for punch press lot size is 12 minutes Time to convey the raw material to punch press is 10 minutes The system operates 8-hour shift a day. a) b) c) Where should the production ordering signal kanban be placed at the grinding station. d) Where the material ordering kanban be placed at the grinding station. 3. Consider a flow line below Find the minimum production lot size at the punch press. Find the kanban eyele time at the punch press. 2 The following table provides all the information need for designing Kanban control or Conwip control on this line. All times are in minutes. 3. Consider a flow line below 1 2 The following table provides all the information need for designing Kanban control or Conwip control on this line. All times are in minutes. 1 2 Kanban waiting at the receiving post Transfer of Kanban 5 to Ordering Post Wait at the Unit processing time 6 Ordering Post Internal Setup time 10 1 Container transfer time to downstream buffer Waiting time in the 6 buffer 4 5 Machines (all data in minutes) 2 3 7 12 2 4 3 4 3 4 5 6 14 3 4 4 7 4 3 5 5 8 2 4 5 5 2 5 4 7 2 6 4 5 The daily demand is known to be 400 units per day. It is also known that the batch size for this line is 25 units per container. The line operates 24 hours each day without breaks. a) Calculate the needed number of Kanban cards if each station will be controlled by Kanban. Use 10% safety factor. b) If the entire line is to be controlled by Conwip system what should be the number of cards needed. For this, use 10% safety factor, and assume the card travel time from machine 5 to machine 1 is 10 minutes. c) Which machine is the bottleneck machine on this line? Why? d) Now assume that we will implement DBR technique to this line. I.e., the machines from Machine #1 to the bottleneck machine (inclusive) will be controlled by Conwip. Once the batch clears the bottleneck machine, it will travel the remaining machines in a push fashion without any delay (pull-push system). Calculate the number of cards needed on the Conwip side of the line. Again use 10% for safety factor and assume that the card transfer time from your bottleneck machine to machine #1 is 10 minutes.

Step by Step Solution

★★★★★

3.43 Rating (166 Votes )

There are 3 Steps involved in it

Step: 1

1 a 1750252 hrs is required for each setup including internal setup and external setup Therefore set...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started