Question

The demand for products A and B is shown below. A manufacturing company wants to determine the production schedule for the next three months that

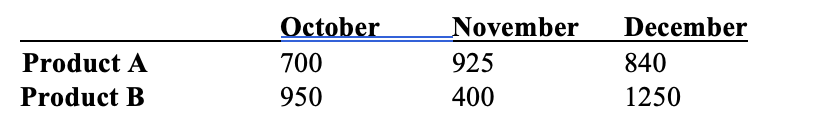

The demand for products A and B is shown below.

A manufacturing company wants to determine the production schedule for the next three months that will satisfy the demand. At the start of the month of October, the warehouse was empty (i.e. no item in stock). The warehouse can store at most 2000 units of product A and B combined. Holding/Inventory costs for both types is $0.25 per month. Because employees are expected to take time off over the Christmas holiday, the company wants to have at least 800 units of product A and 850 units of product B in the warehouse at the beginning of January. Production costs are $2 per unit for product A and $3 per unit for product B. Since the demand for raw materials is rising, production costs are expected to rise by $0.25 from one month to the next (i.e. $0.25 per month through the end of the year). Product A requires 24 minutes of labor per unit and Product B requires 30 minutes of labor per unit. The company has agreed to schedule at least 1200 hours per month of labor. As many as 300 extra hours per month are available for the months of October and November. As for the month of December only 150 extra hours are available. Formulate algebraically the above multiperiod production planning problem to determine the production schedule for products A and B for the three months that will minimize the total production and holding/inventory costs. Define the decision variables, objective function, and constraints. DO NOT SOLVE.

A manufacturing company wants to determine the production schedule for the next three months that will satisfy the demand. At the start of the month of October, the warehouse was empty (i.e. no item in stock). The warehouse can store at most 2000 units of product A and B combined. Holding/Inventory costs for both types is $0.25 per month. Because employees are expected to take time off over the Christmas holiday, the company wants to have at least 800 units of product A and 850 units of product B in the warehouse at the beginning of January. Production costs are $2 per unit for product A and $3 per unit for product B. Since the demand for raw materials is rising, production costs are expected to rise by $0.25 from one month to the next (i.e. $0.25 per month through the end of the year). Product A requires 24 minutes of labor per unit and Product B requires 30 minutes of labor per unit. The company has agreed to schedule at least 1200 hours per month of labor. As many as 300 extra hours per month are available for the months of October and November. As for the month of December only 150 extra hours are available. Formulate algebraically the above multiperiod production planning problem to determine the production schedule for products A and B for the three months that will minimize the total production and holding/inventory costs. Define the decision variables, objective function, and constraints. DO NOT SOLVE.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started