The Design Engineering Manager has given you the following assignment. It's Friday 4:45PM and you want to get the heck outta Dodge by 5:00PM because the Hottest Date Of The Century is waiting out in the parking lot. You'd better hurry. Select a Delrin acetal material to fit the following requirements: parts = a plastic worm drive gear set used in a photocopier injection moldable (consider viscosity & thermal stability) has sufficient lubricity because the parts have sliding contact need moderately high tensile strength but also must be tough to survive shock loads wear resistance for service life = 10 million cycles without excessive wear

Part 1: Use the following tables to select ONE suitable material. Part 2: Explain your choice in terms of the material properties given in the following tables

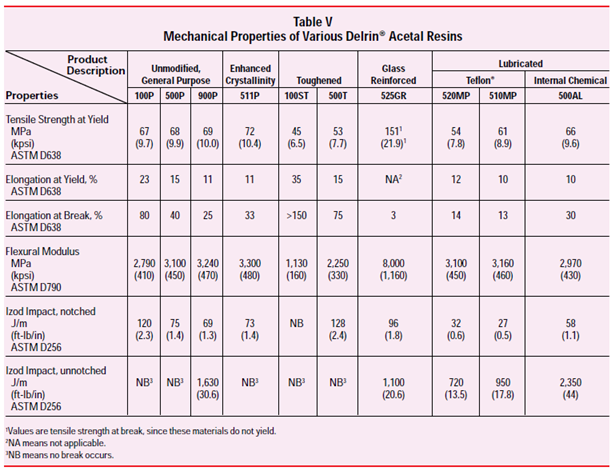

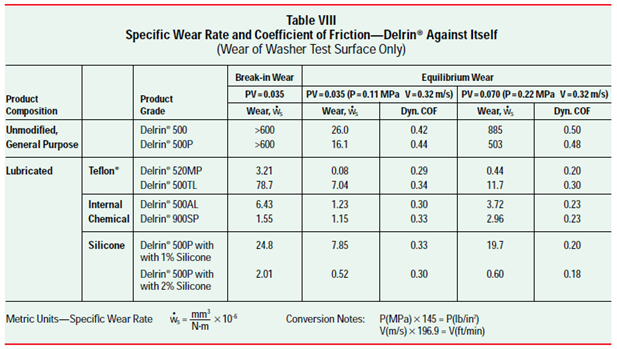

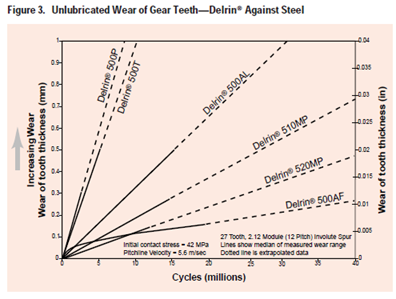

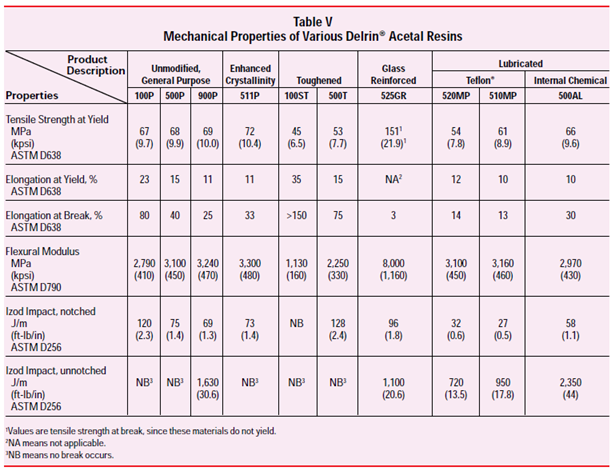

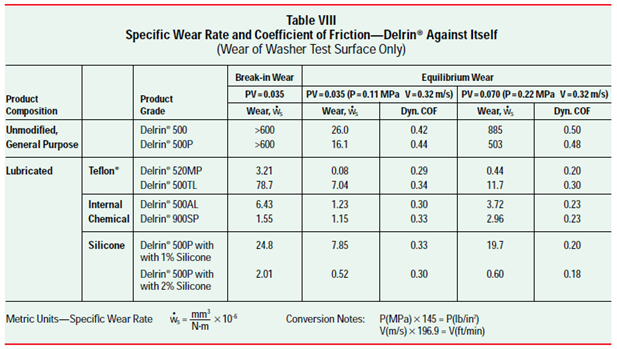

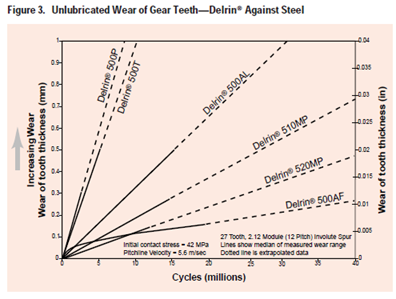

Product Composition Unmodified, General Purpose Enhanced Crystallinity Toughened Table III Delrin Acetal ResinsCommon Compositions for Gears Product Grade Description Delrin 100 High viscosity, maximum toughness Delrin 100P High viscosity, tough, improved mold release and thermal stabilizing system Delrin 500 Medium viscosity Delrin 500P Medium viscosity, improved mold release and thermal stabilizing system Delrin 900 Low viscosity, high flow Delrin 900P Low viscosity, high flow, improved mold release and thermal stabilizing system Delrin 1700P Ultra-low viscosity, maximum flow, improved mold release and thermal stabilizing system Delrin 111P High viscosity, enhanced crystallinity, improved thermal stabilizing system Delrin 5110 Medium viscosity, enhanced crystallinity, improved thermal stabilizing system Delrin 911P Low viscosity, enhanced crystallinity, improved thermal stabilizing system Delrin 100ST High viscosity, super tough Delrin 500MT Medium viscosity, medium toughened, improved thermal stabilizing system Delrin 500T Medium viscosity, toughened Glass Delrin 525GR Medium viscosity, 25% glass reinforced improved thermal stabilizing system Delrin 510GR Medium viscosity, 10% glass reinforced, improved thermal stabilizing system Kevlar Delrin 100KM High viscosity, modified with Kevlar aramid resin, improved thermal stabilizing system Teflon Delrin 100AF High viscosity, tough, 20% Teflon PTFE fibers, improved thermal stabilizing system Delrin 500AF Medium viscosity, 20% Teflon PTFE fibers, improved thermal stabilizing system Delrin 520MP Medium viscosity. 20% Teflon PTFE micropowder, improved thermal stabilizing system Delrin 510MP Medium viscosity, 10% Teflon PTFE micropowder, improved thermal stabilizing system Delrin 500TL Medium viscosity. 1.5% Teflon PTFE micropowder Internal Delrin 500AL Medium viscosity, advanced lubricant system, improved thermal stabilizing system Chemical Delrin 500CL Medium viscosity, chemical lubricant Delrin 900SP Low viscosity, proprietary lubricant, improved thermal stabilizing system Silicone Delrin 500SC 20% Silicone concentrate, typically let down to 1% or 2% Reinforced/ Modified Lubricated (1.7) (9.6) Table V Mechanical Properties of Various Delrin Acetal Resins Product Description Unmodified, Enhanced Glass Lubricated General Purpose Crystallinity Toughened Reinforced Tetlon Internal Chemical Properties 100P 500P 900P 511P 100ST 500T 525GR 520MP 510MP 500AL Tensile Strength at Yield MP 67 68 69 72 45 53 151 54 61 66 (kpsi) (9.7) (9.9) (10.0) (10.4) (6.5) (21.9) (7.8) (8.9) ASTM D638 Elongation at Yield, % 23 15 11 11 35 15 NA 12 10 10 ASTM D638 Elongation at Break, % 80 40 25 33 >150 75 3 14 13 30 ASTM D638 Flexural Modulus MP 2,790 3,100 3.240 3,300 1,130 2.250 8,000 3,100 3,160 2.970 (kpsi) (410) (450) (470) (480) (160) (330) (1.160) (450) (460) (430) ASTM D790 Izod Impact, notched J/m 120 75 69 73 NB 128 96 32 27 58 (ft-lb/in) (2.3) (1.4) (1.3) (1.4) (2.4) (1.8) (0.6) (0.5) (1.1) ASTM D256 Izod Impact, unnotched J/m NB NB 1,630 NB NB 1.100 950 2.350 (ft-lb/in) (30.6) (20.6) (13.5) (17.8) (44) ASTM D256 Values are tensile strength at break, since these materials do not yield. NA means not applicable. "NB means no break occurs. NB 720 Table VIII Specific Wear Rate and Coefficient of Friction-Delrin Against Itself (Wear of Washer Test Surface Only) Product Composition Unmodified, General Purpose Lubricated Break-in Wear PV-0.035 Wear, vis >600 >600 Equilibrium Wear PV = 0.035 (P = 0.11 MPa V-0.32 m/s) PV -0.070 (P=0.22 MPa V-0.32 m/s) Wear, vi Dyn. COF Wear, vis Dyn. COF 26.0 0.42 885 0.50 16.1 0.44 0.48 503 3.21 78.7 0.08 7.04 0.44 11.7 0.20 0.30 Product Grade Delrin 500 Delrin 500P Teflon Delrin 520MP Delrin 500TL Internal Delrin 500AL Chemical Delrin 900SP Silicone Delrin 500P with with 1% Silicone Delrin 500P with with 2% Silicone 0.29 0.34 0.30 0.33 6.43 1.55 1.23 1.15 3.72 2.96 0.23 0.23 24.8 7.85 0.33 19.7 0.20 2.01 0.52 0.30 0.60 0.18 Metric UnitsSpecific Wear Rate mm x 10 N-m Conversion Notes: P(MPa) x 145 = P(Ib/in) V(m/s) 196.9 = V(ft/min) Figure 3. Unlubricated Wear of Gear TeethDelrin Against Steel 0035 Delrin 500P 0 Delrin 500T #1 OZ Delrin 500AL 06 Increasing Wear Wear of tooth thickness (mm) 05 Delrine 510MP -0.02 Wear of tooth thickness (in) 04 40.015 Delrin 520MP 034 Delrin 500AF. 5001 02 -0.005 27 Tooth, 2.12 Module (12 Pich involute Spur Intial contact stress - 12 MP3 Lines show median of measured wear range Pachine Velocity - 5.5 mibe Dotted line is extrapolated data Cycles (millions)