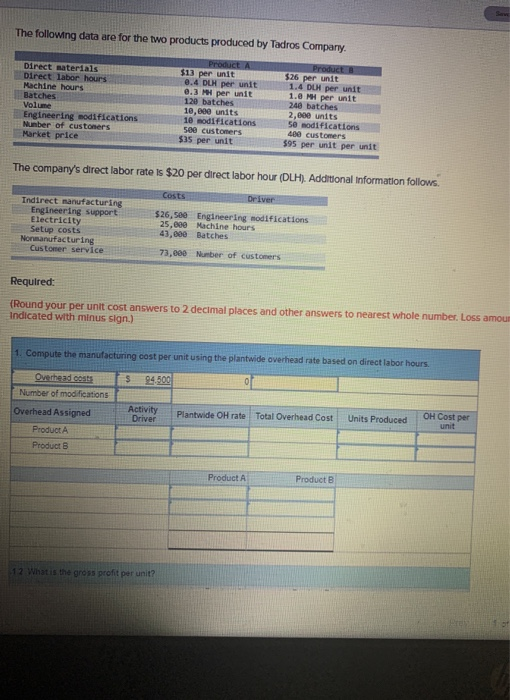

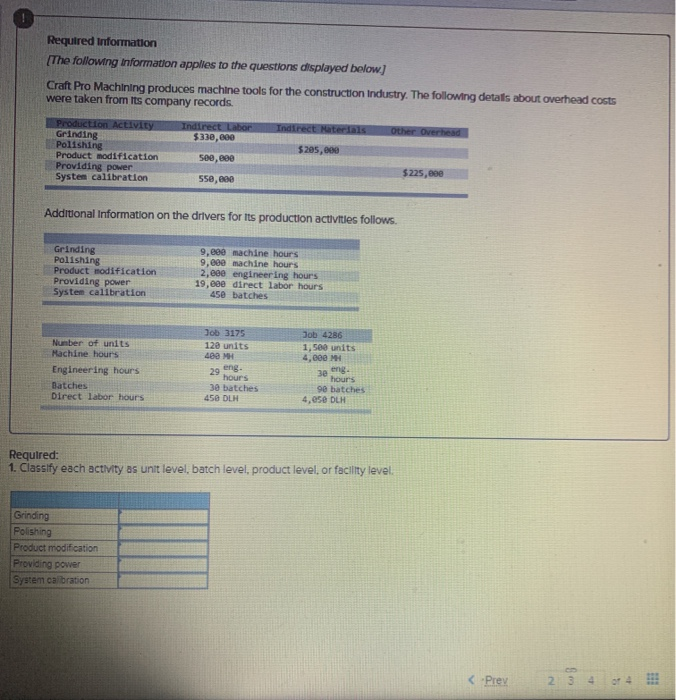

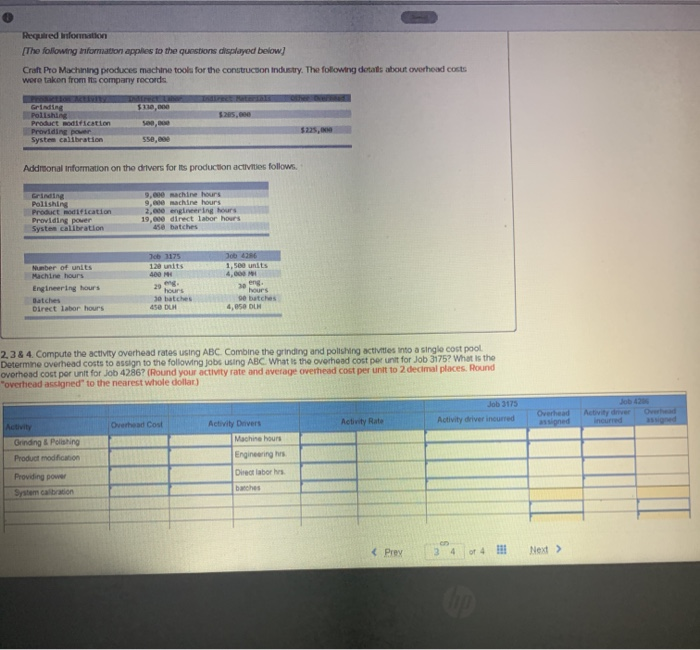

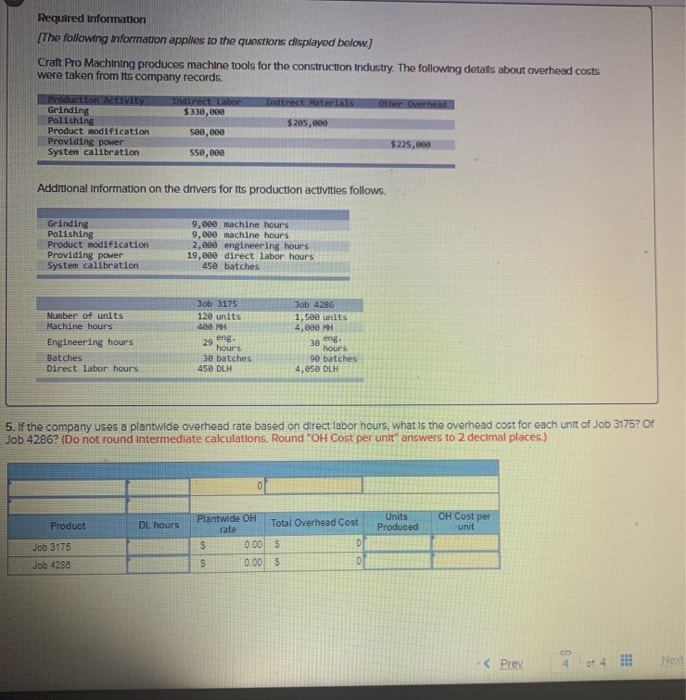

The following data are for the two products produced by Tadros Company Direct materials Direct Labor hours Machine hours Batches Volume Engineering modifications Number of customers Market price Product A $13 per unit 0.4 DLH per unit 0.3 M per unit 120 batches 10,000 units 10 modifications 500 customers $35 per unit Product $26 per unit 1.4 DLH per unit 1.0 M per unit 240 batches 2,000 units 50 modifications 400 customers $95 per unit per unit The company's direct labor rate is $20 per direct labor hour (DLH). Additional Information follows. Costs Driver Indirect manufacturing Engineering support Electricity Setup costs Nonmanufacturing Customer service $26,5ee Engineering modifications 25,000 Machine hours 43,000 Batches 73,00e Number of customers Required: (Round your per unit cost answers to 2 decimal places and other answers to nearest whole number. Loss amoum Indicated with minus sign.) 1. Compute the manufacturing cost per unit using the plantwide overhead rate based on direct labor hours. $ 94.500 Overhead costs Number of modifications Overhead Assigned Product Products Activity Driver Plantwide OH rate Total Overhead Cost Units Produced OH Cost per unit Product Product B 12 What is the gross profit per unit? Required Information (The following information applies to the questions displayed below) Craft Pro Machining produces machine tools for the construction Industry. The following details about overhead costs were taken from its company records. Indirect Labor $330,000 Indirect Materials Other Overhead Production Activity Grinding Polishing Product modification Providing power System calibration szes, 500,000 $225,000 550, eee Additional Information on the drivers for its production activities follows. Grinding Polishing Product modification Providing power System calibration 9,000 machine hours 9,000 machine hours 2, cee engineering hours 19,000 direct labor hours 450 batches Job 3175 120 units 400 MH Job 4286 1,500 units 4,600 M Number of units Machine hours Engineering hours Batches Direct Labor hours 29 eng. 3e eng. hours 30 batches 450 DLH hours 90 batches 4,050 DLH Required: 1. Classify each activity as unit level, batch level, product level, or facility level. Grinding Polishing Product modification Providing power System calibration Required Information The following Information applies to the questions displayed below.) Craft Pro Machining produces machine tools for the construction Industry. The following details about overhead costs were taken from its company records. Indirect Labor $330,000 Indirect Materials Other Overhead Production Activity Grinding Polishing Product modification Providing power System calibration $ 205,000 500,000 $225,000 550,000 Additional Information on the drivers for its production activities follows. Grinding Polishing Product modification Providing power System calibration 9,000 machine hours 9,000 machine hours 2,800 engineering hours 19,000 direct labor hours 450 batches Job 4286 1,500 units 4.ee Number of units Machine hours Engineering hours Batches Direct labor hours Job 3175 120 units 400 MM 29 eng. hours 30 batches 450 DLH 39 eng. hour's 90 batches 4,050 DLH 5. If the company uses a plantwide overhead rate based on direct labor hours, what is the overhead cost for each unit of Job 3175? Of Job 4286? (Do not round Intermediate calculations, Round "OH Cost per unit" answers to 2 decimal places.) 0 Product OH Cost per unit DL hours Total Overhead Cost Units Produced Plantwide OH rate $ 0.00 $ 0.00 $ Job 3175 Job 4286 0 $ 0