Answered step by step

Verified Expert Solution

Question

1 Approved Answer

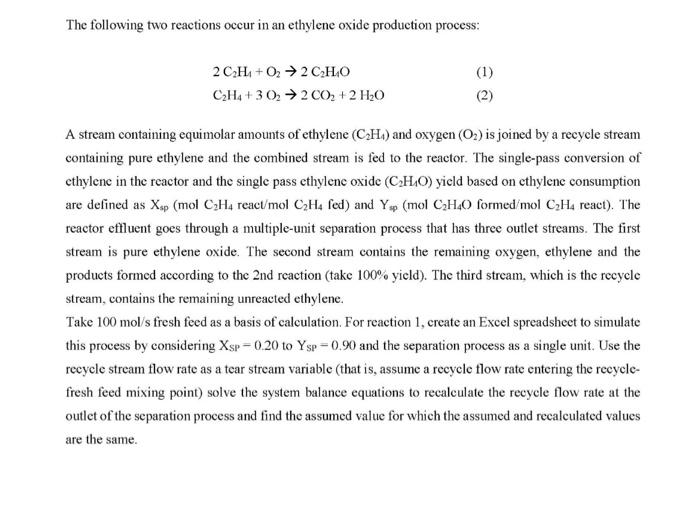

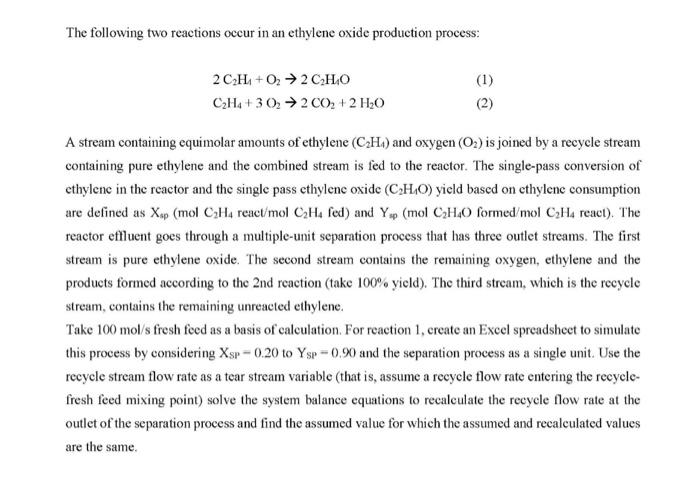

The following two reactions occur in an ethylene oxide production process: 2 CH + O2 2 CH4O CH4+3 02 CO + 2 HO e (2)

The following two reactions occur in an ethylene oxide production process: 2 CH + O2 2 CH4O CH4+3 02 CO + 2 HO e (2) A stream containing equimolar amounts of ethylene (CH4) and oxygen (O) is joined by a recycle stream containing pure ethylene and the combined stream is fed to the reactor. The single-pass conversion of ethylene in the reactor and the single pass ethylene oxide (CH4O) yield based on ethylene consumption are defined as Xsp (mol CH4 react/mol CH4 fed) and Ysp (mol CH4O formed/mol CH4 react). The reactor effluent goes through a multiple-unit separation process that has three outlet streams. The first stream is pure ethylene oxide. The second stream contains the remaining oxygen, ethylene and the products formed according to the 2nd reaction (take 100% yield). The third stream, which is the recycle stream, contains the remaining unreacted ethylene. Take 100 mol/s fresh feed as a basis of calculation. For reaction 1, create an Excel spreadsheet to simulate this process by considering XSP = 0.20 to Ysp = 0.90 and the separation process as a single unit. Use the recycle stream flow rate as a tear stream variable (that is, assume a recycle flow rate entering the recycle- fresh feed mixing point) solve the system balance equations to recalculate the recycle flow rate at the outlet of the separation process and find the assumed value for which the assumed and recalculated values are the same.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started