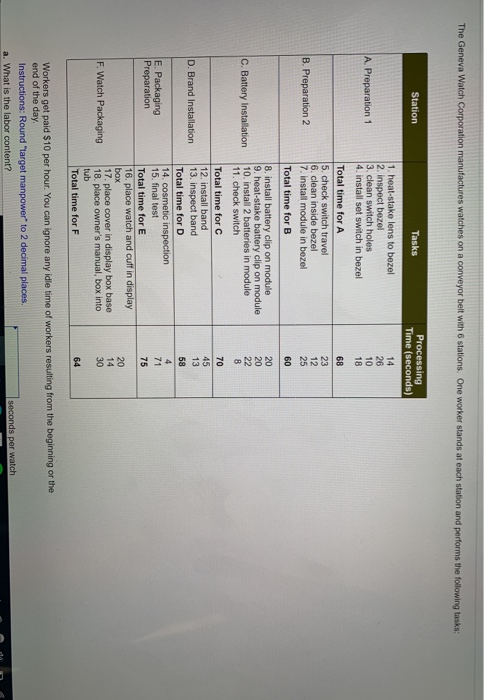

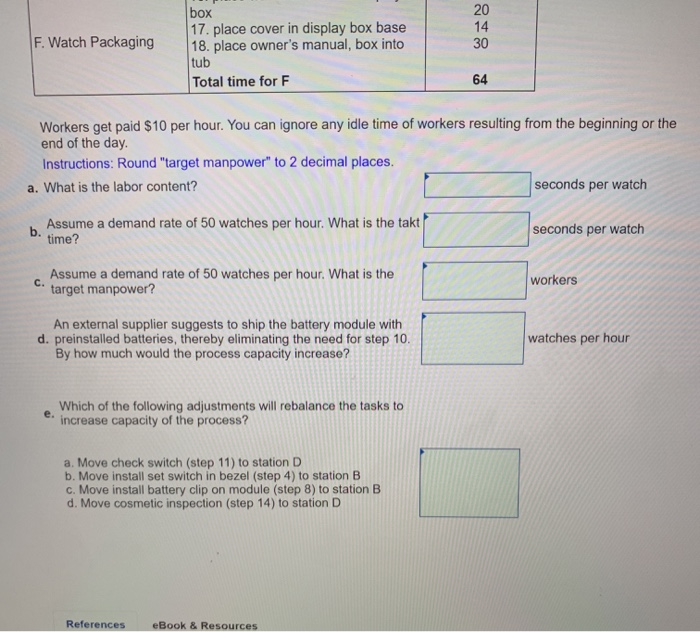

The Geneva Watch Corporation manufactures watches on a conveyor belt with 6 stations. One worker stands at each station and performs the following tasks: Station Tasks Processing Time (seconds) 1. heat-stake lens to bezel 2. inspect bezel 3. clean switch holes 4. install set switch in bezel 14 26 10 18 A. Preparation 1 Total time for A 5. check switch travel 6. clean inside bezel 7. install module in bozel Total time for 68 23 12 25 60 B. Preparation 2 8. install battery clip on module 9. heat-stake battery clip on module 10. install 2 batteries in module 11. check switch 20 20 22 8 C. Battery Installation D. Brand Installation Total time for C 12. install band 13. inspect band Total time for D 14. cosmetic inspection 15. final test Total time for E 16. place watch and cuff in display box 17. place cover in display box base 18. place owner's manual, box into tub Total time for F 70 45 13 58 4 71 75 E. Packaging Preparation 20 14 30 F. Watch Packaging 64 Workers get paid $10 per hour. You can ignore any idle time of workers resulting from the beginning or the end of the day Instructions: Round "target manpower to 2 decimal places. a. What is the labor content? seconds per watch box 17. place cover in display box base 18. place owner's manual, box into tub Total time for F 20 14 30 F. Watch Packaging 64 Workers get paid $10 per hour. You can ignore any idle time of workers resulting from the beginning or the end of the day Instructions: Round "target manpower" to 2 decimal places. a. What is the labor content? seconds per watch b. Assume a demand rate of 50 watches per hour. What is the takt time? seconds per watch c. Assume a demand rate of 50 watches per hour. What is the target manpower? workers An external supplier suggests to ship the battery module with d. preinstalled batteries, thereby eliminating the need for step 10. By how much would the process capacity increase? watches per hour e. Which of the following adjustments will rebalance the tasks to increase capacity of the process? a. Move check switch (step 11) to station D b. Move install set switch in bezel (step 4) to station B c. Move install battery clip on module (step 8) to station B d. Move cosmetic inspection (step 14) to station D References eBook & Resources The Geneva Watch Corporation manufactures watches on a conveyor belt with 6 stations. One worker stands at each station and performs the following tasks: Station Tasks Processing Time (seconds) 1. heat-stake lens to bezel 2. inspect bezel 3. clean switch holes 4. install set switch in bezel 14 26 10 18 A. Preparation 1 Total time for A 5. check switch travel 6. clean inside bezel 7. install module in bozel Total time for 68 23 12 25 60 B. Preparation 2 8. install battery clip on module 9. heat-stake battery clip on module 10. install 2 batteries in module 11. check switch 20 20 22 8 C. Battery Installation D. Brand Installation Total time for C 12. install band 13. inspect band Total time for D 14. cosmetic inspection 15. final test Total time for E 16. place watch and cuff in display box 17. place cover in display box base 18. place owner's manual, box into tub Total time for F 70 45 13 58 4 71 75 E. Packaging Preparation 20 14 30 F. Watch Packaging 64 Workers get paid $10 per hour. You can ignore any idle time of workers resulting from the beginning or the end of the day Instructions: Round "target manpower to 2 decimal places. a. What is the labor content? seconds per watch box 17. place cover in display box base 18. place owner's manual, box into tub Total time for F 20 14 30 F. Watch Packaging 64 Workers get paid $10 per hour. You can ignore any idle time of workers resulting from the beginning or the end of the day Instructions: Round "target manpower" to 2 decimal places. a. What is the labor content? seconds per watch b. Assume a demand rate of 50 watches per hour. What is the takt time? seconds per watch c. Assume a demand rate of 50 watches per hour. What is the target manpower? workers An external supplier suggests to ship the battery module with d. preinstalled batteries, thereby eliminating the need for step 10. By how much would the process capacity increase? watches per hour e. Which of the following adjustments will rebalance the tasks to increase capacity of the process? a. Move check switch (step 11) to station D b. Move install set switch in bezel (step 4) to station B c. Move install battery clip on module (step 8) to station B d. Move cosmetic inspection (step 14) to station D References eBook & Resources