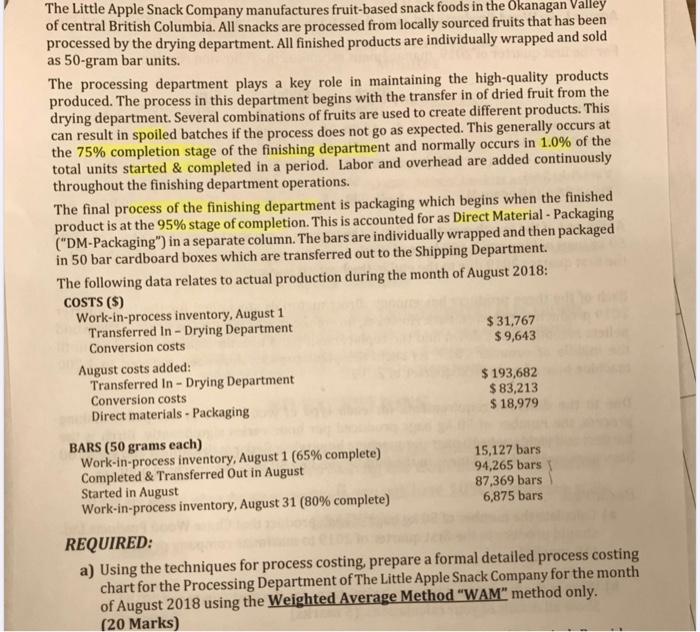

The Little Apple Snack Company manufactures fruit-based snack foods in the Okanagan Valley of central British Columbia. All snacks are processed from locally sourced fruits that has been processed by the drying department. All finished products are individually wrapped and sold as 50-gram bar units. The processing department plays a key role in maintaining the high-quality products produced. The process in this department begins with the transfer in of dried fruit from the drying department. Several combinations of fruits are used to create different products. This can result in spoiled batches if the process does not go as expected. This generally occurs at the 75% completion stage of the finishing department and normally occurs in 1.0% of the total units started \& completed in a period. Labor and overhead are added continuously throughout the finishing department operations. The final process of the finishing department is packaging which begins when the finished product is at the 95% stage of completion. This is accounted for as Direct Material - Packaging ("DM-Packaging") in a separate column. The bars are individually wrapped and then packaged in 50 bar cardboard boxes which are transferred out to the Shipping Department. The following data relates to actual production during the month of August 2018: REQUIRED: a) Using the techniques for process costing, prepare a formal detailed process costing chart for the Processing Department of The Little Apple Snack Company for the month of August 2018 using the Weighted Average Method "WAM" method only. (20 Marks) The Little Apple Snack Company manufactures fruit-based snack foods in the Okanagan Valley of central British Columbia. All snacks are processed from locally sourced fruits that has been processed by the drying department. All finished products are individually wrapped and sold as 50-gram bar units. The processing department plays a key role in maintaining the high-quality products produced. The process in this department begins with the transfer in of dried fruit from the drying department. Several combinations of fruits are used to create different products. This can result in spoiled batches if the process does not go as expected. This generally occurs at the 75% completion stage of the finishing department and normally occurs in 1.0% of the total units started \& completed in a period. Labor and overhead are added continuously throughout the finishing department operations. The final process of the finishing department is packaging which begins when the finished product is at the 95% stage of completion. This is accounted for as Direct Material - Packaging ("DM-Packaging") in a separate column. The bars are individually wrapped and then packaged in 50 bar cardboard boxes which are transferred out to the Shipping Department. The following data relates to actual production during the month of August 2018: REQUIRED: a) Using the techniques for process costing, prepare a formal detailed process costing chart for the Processing Department of The Little Apple Snack Company for the month of August 2018 using the Weighted Average Method "WAM" method only. (20 Marks)