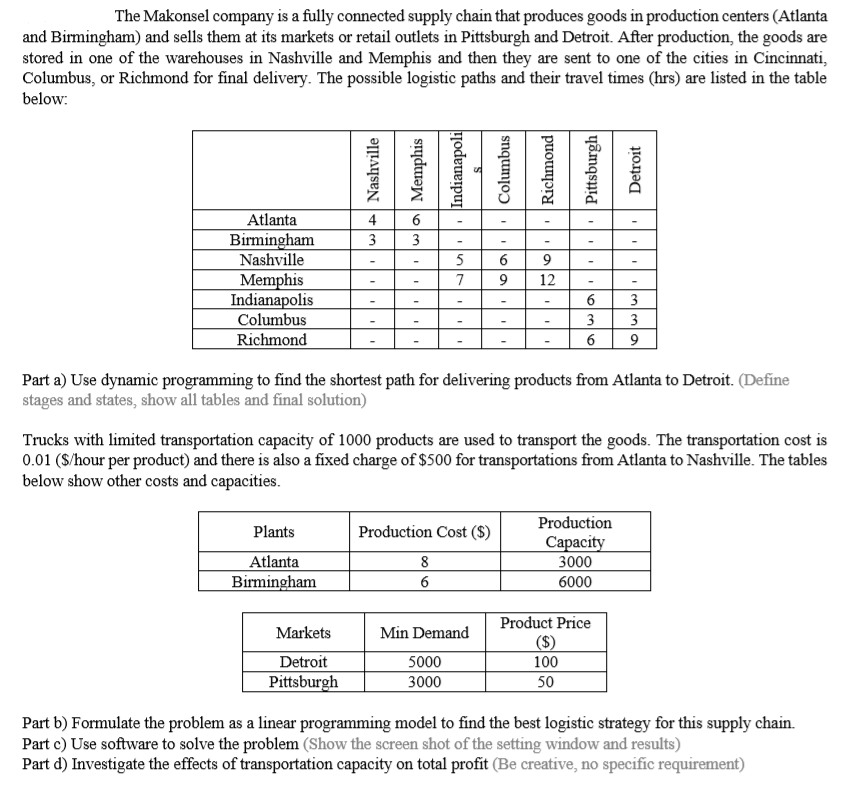

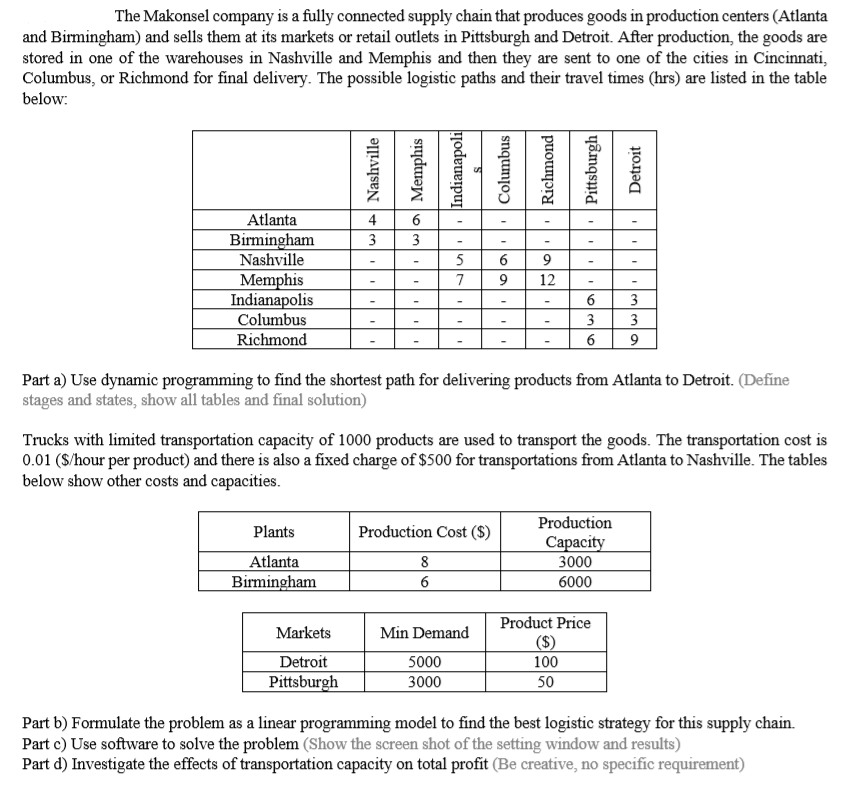

The Makonsel company is a fully connected supply chain that produces goods in production centers (Atlanta and Birmingham) and sells them at its markets or retail outlets in Pittsburgh and Detroit. After production, the goods are stored in one of the warehouses in Nashville and Memphis and then they are sent to one of the cities in Cincinnati, Columbus, or Richmond for final delivery. The possible logistic paths and their travel times (hrs) are listed in the table below: Nashville wa Memphis Indianapoli Columbus Richmond Detroit Pittsburgh 9. Atlanta Birmingham Nashville Memphis Indianapolis Columbus Richmond awa 69 Part a) Use dynamic programming to find the shortest path for delivering products from Atlanta to Detroit. (Define stages and states, show all tables and final solution) Trucks with limited transportation capacity of 1000 products are used to transport the goods. The transportation cost is 0.01 ($/hour per product) and there is also a fixed charge of $500 for transportations from Atlanta to Nashville. The tables below show other costs and capacities. Plants Production Cost ($) Production Capacity 3000 6000 Atlanta Birmingham 6 Markets Product Price ($) 100 50 Min Demand 5000 3000 Detroit Pittsburgh Part b) Formulate the problem as a linear programming model to find the best logistic strategy for this supply chain. Part c) Use software to solve the problem (Show the screen shot of the setting window and results) Part d) Investigate the effects of transportation capacity on total profit (Be creative, no specific requirement) The Makonsel company is a fully connected supply chain that produces goods in production centers (Atlanta and Birmingham) and sells them at its markets or retail outlets in Pittsburgh and Detroit. After production, the goods are stored in one of the warehouses in Nashville and Memphis and then they are sent to one of the cities in Cincinnati, Columbus, or Richmond for final delivery. The possible logistic paths and their travel times (hrs) are listed in the table below: Nashville wa Memphis Indianapoli Columbus Richmond Detroit Pittsburgh 9. Atlanta Birmingham Nashville Memphis Indianapolis Columbus Richmond awa 69 Part a) Use dynamic programming to find the shortest path for delivering products from Atlanta to Detroit. (Define stages and states, show all tables and final solution) Trucks with limited transportation capacity of 1000 products are used to transport the goods. The transportation cost is 0.01 ($/hour per product) and there is also a fixed charge of $500 for transportations from Atlanta to Nashville. The tables below show other costs and capacities. Plants Production Cost ($) Production Capacity 3000 6000 Atlanta Birmingham 6 Markets Product Price ($) 100 50 Min Demand 5000 3000 Detroit Pittsburgh Part b) Formulate the problem as a linear programming model to find the best logistic strategy for this supply chain. Part c) Use software to solve the problem (Show the screen shot of the setting window and results) Part d) Investigate the effects of transportation capacity on total profit (Be creative, no specific requirement)