Question

The manager of the OBrian Glass Company is planning the production of automobile windshields for the next four months. The demand for the next four

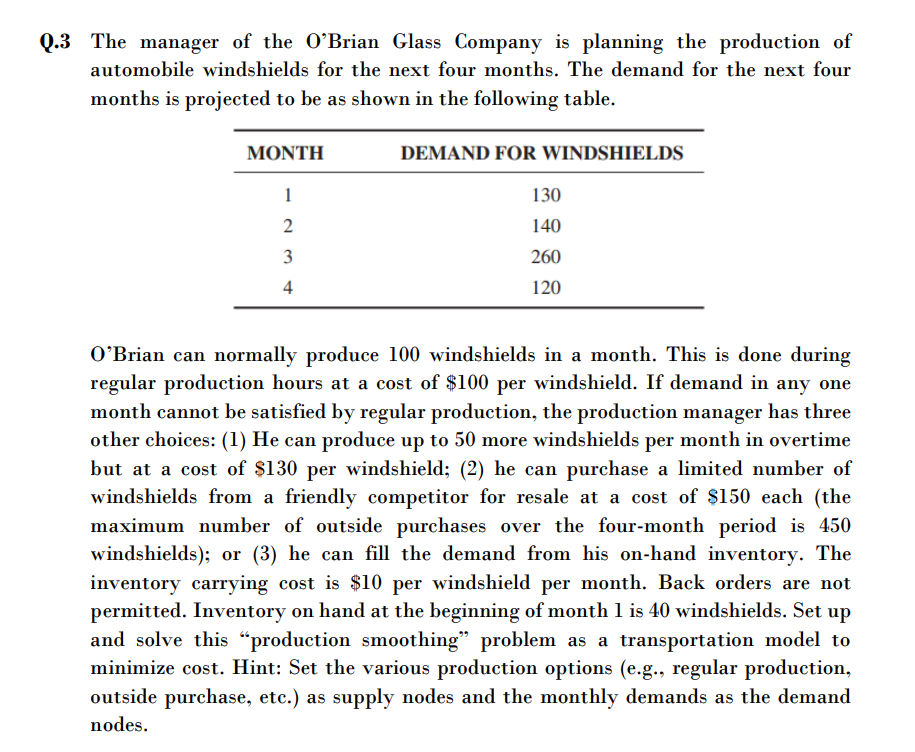

The manager of the OBrian Glass Company is planning the production of automobile windshields for the next four months. The demand for the next four months is projected to be as shown in the following table. OBrian can normally produce 100 windshields in a month. This is done during regular production hours at a cost of $100 per windshield. If demand in any one month cannot be satisfied by regular production, the production manager has three other choices: (1) He can produce up to 50 more windshields per month in overtime but at a cost of $130 per windshield; (2) he can purchase a limited number of windshields from a friendly competitor for resale at a cost of $150 each (the maximum number of outside purchases over the four-month period is 450 windshields); or (3) he can fill the demand from his on-hand inventory. The inventory carrying cost is $10 per windshield per month. Back orders are not permitted. Inventory on hand at the beginning of month 1 is 40 windshields. Set up and solve this production smoothing problem as a transportation model to minimize cost. Hint: Set the various production options (e.g., regular production, outside purchase, etc.) as supply nodes and the monthly demands as the demand nodes.

.3 The manager of the O'Brian Glass Company is planning the production of automobile windshields for the next four months. The demand for the next four months is projected to be as shown in the following table. O'Brian can normally produce 100 windshields in a month. This is done during regular production hours at a cost of $100 per windshield. If demand in any one month cannot be satisfied by regular production, the production manager has three other choices: (1) He can produce up to 50 more windshields per month in overtime but at a cost of $130 per windshield; (2) he can purchase a limited number of windshields from a friendly competitor for resale at a cost of $150 each (the maximum number of outside purchases over the four-month period is 450 windshields); or (3) he can fill the demand from his on-hand inventory. The inventory carrying cost is $10 per windshield per month. Back orders are not permitted. Inventory on hand at the beginning of month 1 is 40 windshields. Set up and solve this "production smoothing" problem as a transportation model to minimize cost. Hint: Set the various production options (e.g., regular production, outside purchase, etc.) as supply nodes and the monthly demands as the demand nodes

.3 The manager of the O'Brian Glass Company is planning the production of automobile windshields for the next four months. The demand for the next four months is projected to be as shown in the following table. O'Brian can normally produce 100 windshields in a month. This is done during regular production hours at a cost of $100 per windshield. If demand in any one month cannot be satisfied by regular production, the production manager has three other choices: (1) He can produce up to 50 more windshields per month in overtime but at a cost of $130 per windshield; (2) he can purchase a limited number of windshields from a friendly competitor for resale at a cost of $150 each (the maximum number of outside purchases over the four-month period is 450 windshields); or (3) he can fill the demand from his on-hand inventory. The inventory carrying cost is $10 per windshield per month. Back orders are not permitted. Inventory on hand at the beginning of month 1 is 40 windshields. Set up and solve this "production smoothing" problem as a transportation model to minimize cost. Hint: Set the various production options (e.g., regular production, outside purchase, etc.) as supply nodes and the monthly demands as the demand nodes Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started