Answered step by step

Verified Expert Solution

Question

1 Approved Answer

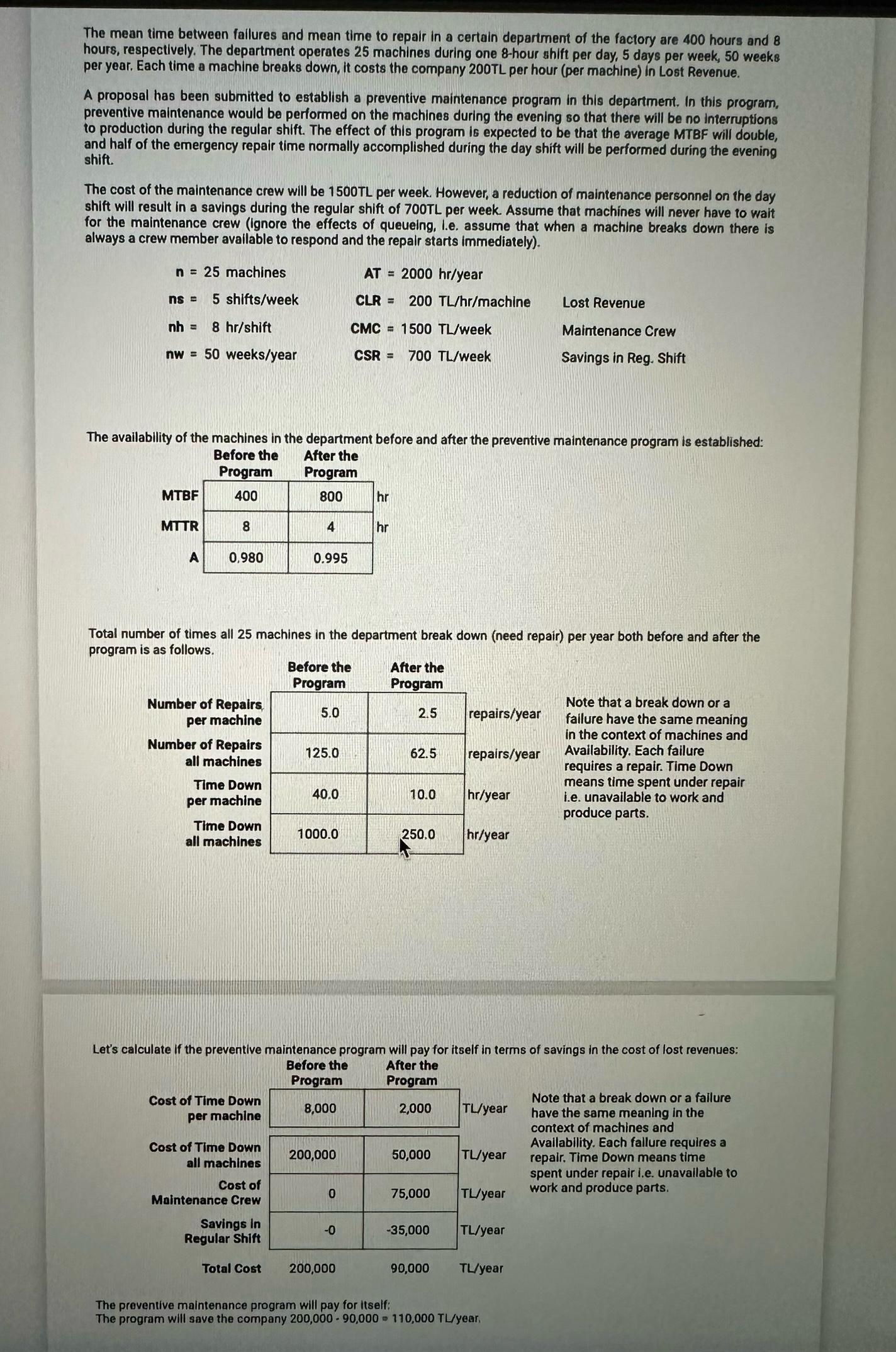

The mean time between fallures and mean time to repair in a certain department of the factory are 4 0 0 hours and 8 hours,

The mean time between fallures and mean time to repair in a certain department of the factory are hours and hours, respectively. The department operates machines during one hour shift per day, days per week, weeks per year. Each time a machine breaks down, it costs the company TL per hour per machine in Lost Revenue.

A proposal has been submitted to establish a preventive maintenance program in this department. In this program, preventive maintenance would be performed on the machines during the evening so that there will be no interruptions to production during the regular shift. The effect of this program is expected to be that the average MTBF will double, and half of the emergency repair time normally accomplished during the day shift will be performed during the evening shift.

The cost of the maintenance crew will be TL per week. However, a reduction of maintenance personnel on the day shift will result in a savings during the regular shift of TL per week. Assume that machines will never have to wait for the maintenance crew ignore the effects of queueing, le assume that when a machine breaks down there is always a crew member available to respond and the repair starts immediately

machines

ear

shifteek

achine

hift

eek

eek

Lost Revenue

weeksyear

Maintenance Crew

Savings in Reg. Shift

The availability of the machines in the department before and after the preventive maintenance program is established:

tabletableBefore theProgramtableAfter theProgramMTBFMTTRA

Total number of times all machines in the department break down need repair per year both before and after the program is as follows.

tabletableBefore theProgramtableAfter theProgramtableNumber of Repairs.per machinerepairtableNumber of Repairsall machinesrepairsyeartableTime Downper machinehryeartableTime Downall machineshryear

Note that a break down or a failure have the same meaning in the context of machines and Availability. Each failure requires a repair. Time Down means time spent under repair ie unavailable to work and produce parts.

Let's calculate if the preventive maintenance program will pay for itself in terms of savings in the cost of lost revenues:

tabletableBefore theProgramtableAfter theProgramtableCost of Time Downper machineTLyeartableNote that a break down or a failurehave the same meaning in thetableCost of Time Downall machinesTLyeartableAvallability Each fallure requires arepair Time Down means timetableCost ofMaintenance CrawTLyearwork and produce parts.tableSavings inRegular ShiftTLyearTotal Cost,TLyear

The preventive maintenance program will pay for itself:

The program will save the company TLyear

SHOW ME HOW WE FOUND EACH answer MATHmeaticlly

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started