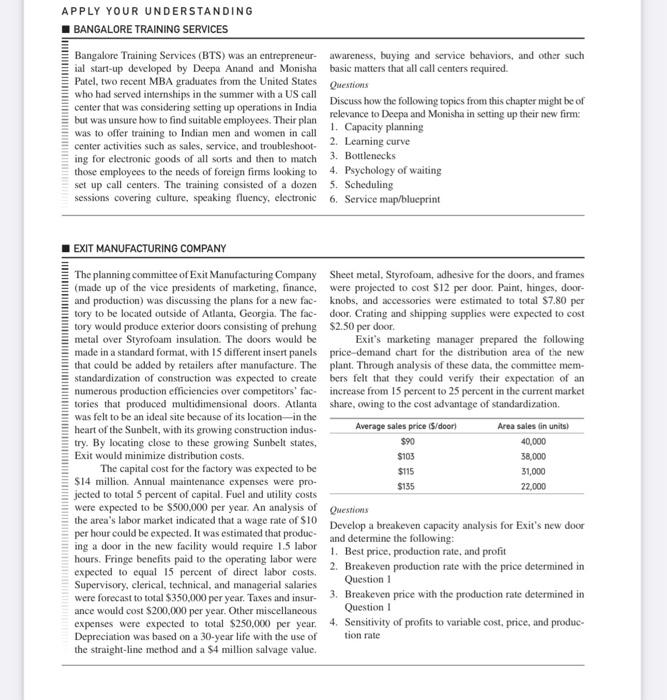

The planning committee of Exit Manufacturing Company (made up of the vice presidents of marketing, finance, and production) was discussing the plans for a new factory to be located outside of Atlanta, Georgia. The factory would produce exterior doors consisting of prehung metal over Styrofoam insulation. The doors would be made in a standard format, with 15 different insert panels that could be added by retailers after manufacture. The standardization of construction was expected to create numerous production efficiencies over competitors' factories that produced multidimensional doors. Atlanta was felt to be an ideal site because of its location - in the heart of the Sunbelt, with its growing construction industry. By locating close to these growing Sunbelt states, Exit would minimize distribution costs. The capital cost for the factory was expected to be $14 million. Annual maintenance expenses were projected to total 5 percent of capital. Fuel and utility costs were expected to be $500,000 per year. An analysis of the area's labor market indicated that a wage rate of $10 per hour could be expected. It was estimated that producing a door in the new facility would require 1.5 labor hours. Fringe benefits paid to the operating labor were expected to equal 15 pereent of direct labor costs. Supervisory, clerical, technical, and managerial salaries were forecast to total $350,000 per year. Taxes and insurance would cost $200,000 per year. Other miscellancous expenses were expected to total $250,000 per year. Depreciation was based on a 30-year life with the use of the straight-line method and a $4 million salvage value. Sheet metal, Styrofoum, adhesive for the doors, and frames were projected to cost $12 per door. Paint, hinges, doorknobs, and accessories were estimated to total $7.80 per door. Crating and shipping supplies were expected to cost $2.50 per door. Exit's marketing manager prepared the following price-demand chart for the distribution area of the new plant. Through analysis of these data, the committee members felt that they could verify their expectation of an increase from 15 percent to 25 pereent in the current market share, owing to the cost advantage of standardization. Questions Develop a breakeven capacity analysis for Exit's new door and determine the following: 1. Best price, production rate, and profit 2. Breakeven production rate with the price determined in Question 1 3. Breakeven price with the production rate determined in Question I 4. Sensitivity of profits to variable cost, price, and production rate