Question

The ski area uses snowmaking to assure snow coverage on several runs early in the season and at the base area. Snowflake upgraded some of

The ski area uses snowmaking to assure snow coverage on several runs early in the season and at the base area. Snowflake upgraded some of its snowmaking equipment several years ago. The current mix of upgraded compressors and nozzles uses 2.6 KWH per cubic meter of snow produced, and can produce about 17 cubic meters of snow an hour under favorable conditions. Early in the season the area uses snow cannons which use 3.4 KWH per cubic meter of snow, but can produce snow much faster than the nozzle or emitter-type of snow making equipment. Over the course of the winter the ski area will make about 250,000 cubic meters of snow. About 25% is from snow cannons at the beginning of the season. The rest is from more efficient nozzlestype equipment. Recent advances in snowmaking now have nozzles that use just 1.3 KWH of electricity per cubic meter of snow produced and can produce 20 cubic meters of snow per hour. Snowflake Ski Basin 2 Replacing the 120 old-style nozzles with the new snowmaking equipment would cost about $350 per nozzle. This includes new parts, adapters and labor. The change would reduce electricity demand for the entire snowmaking system from 2.8 KWH per cubic meter of snow to about 1.8 KWH. The average would not be the 1.3 KWH of the new nozzles because snow cannons would still be used early in the ski season to get coverage of ski slopes. The new nozzles would last 4 years, then have to be replaced. A 6% discount rate is appropriate.

Don Pouderuse, the director of mountain operations, expects to make 250,000 to 300,000 cubic meters of snow most years.

Lift operations uses slightly more than half of all electricity at the ski area (data is provided in the Data section below). Grooming the slopes requires 5 to 7 large machines running from 5:00 PM through the night. Snowflake has a fleet of 8 Pisten Bully groomers of various ages. One of the older machines is about to be replaced. The replacement will cost $455,000. It has a standard diesel engine but gets slightly better mileage than the existing fleet machines. Over the entire season the machine will be run for about 1,100 hours with a fuel consumption rate of 5.75 gallons of diesel per hour. Pisten Bully has just introduced a hybrid groomer, the 600 E+, that uses electric motor assist to reduce fuel use. The electric-assist reduces diesel fuel consumption (and thereby CO2 emissions) by about 20%. The price of one of these machines is $495,000. It has identical performance to the standard diesel machine. Assume both machines have a life of 20 years and identical maintenance costs. The battery in the 600 E+ is rated at 140 KwH. The battery is partially recharged while the machine is operating through a regenerative braking system. Topping off the battery would require approximately four hours with a 20 Kw fast charger, or about 80 Kwh per day for the 150 days ski season. The cost of the fast charger would be about $800. Installation can be done inhouse. Using a discount rate of 6%, which machine should Snowflake Ski Basin buy?

#2: Pisten Bully replacement: This proposal has two parts. First do a standard NPV analysis, then do a second analysis that includes a carbon tax.

Replacement decisions: The best way to analyze a choice between two machines that do the same job is to compute the differences in cash flows between them. We can use the non-hybrid groomer as the standard and then compute the cost difference of the hybrid machine to it. The hybrid groomer costs $40,000 more than the non-hybrid. But the hybrid uses 20% less fuel. Looking at just the differences: the hybrid groomer requires a $40,000 additional investment that purchases 20 years of fuel savings. These differences will give you the NPV you want, when discounted.

Carbon Tax: Assume that the carbon tax is $60 per mtCO2e in year 1 and increases by $4 per ton each year, so in Year 2 the tax is $64, Year 3 $68, and so on. The best approach is to complete the NPV analysis without the carbon tax, compute the emissions, use those emissions to estimate the tax. Once you have the tax, include that amount in the project cash flows and re-compute the NPV. The avoided emissions stay the same so the tax will be (Quantity x Carbon Price that Year). The carbon tax is a penalty for the high emitting groomer, but a benefit for the 660 E+ hybrid groomer. The tax should increase its benefits.

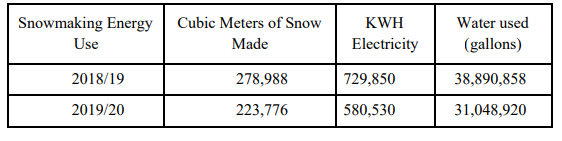

Snowmaking Energy Use Cubic Meters of Snow Made KWH Electricity Water used (gallons) 2018/19 278,988 729,850 38,890,858 2019/20 223,776 580,530 31,048,920 Snowmaking Energy Use Cubic Meters of Snow Made KWH Electricity Water used (gallons) 2018/19 278,988 729,850 38,890,858 2019/20 223,776 580,530 31,048,920Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started