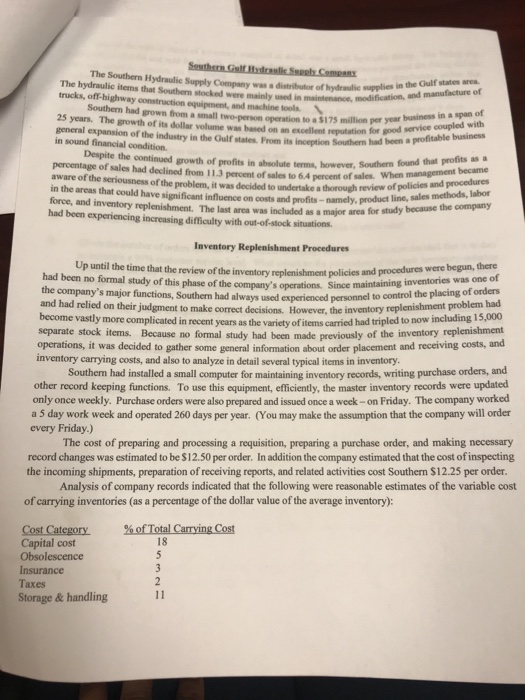

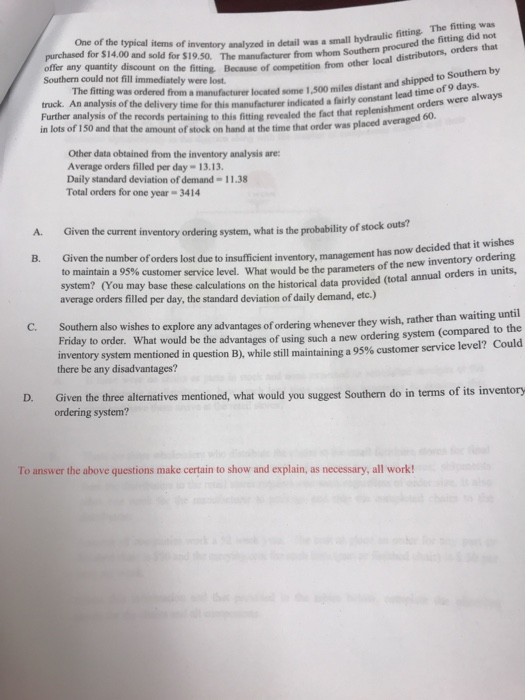

The Southern Hydraulic Supply Company was adistributor of hydraalic supplies nanfacture of The hydraulic items that Southern stocked were mainly used in maintenance, modification, trucks, off-highway construction equipment, and machine tools. the Gulf states area. and manufacture of Southern had grown from a small two-person operation to a $175 million per year 25 years. The growth of its dollar volume was based on an excellent reputation for good general expansion of the industry in the Gulf stales Prom its inception Southern had been a business in a span of in sound financial condition. profitable business Despite the continued growth of profits in absolute terms, however, Southern found that profits asa When management became of policies and procedures percentage of sales had declined from 11.3 percent of sales to 6.4 percent of sales aware of the seriousness of the problem, it was decided to undertake a thorough review in the areas that could have significant influence on costs and profits-namely, product lnempany force, and inventory replenishment. The last area was included as a major area had been experiencing increasing difficulty with out-of-stock situations. line, sales methods, labor for study because Inventory Replenishment Procedures Up until the time that the review of the inventory replenishment policies and procedures were begun, there had been no formal study of this phase of the company's operations the company's major functions, Since maintaining inventories was one of always used experienced personnel to control the placing of orders correct decisions. However, the inventory replenishment problem had Southern had and had relied on their judgment to make become vastly more complicated in recent years as the variety ofitems carried had tripled to now including 15,000 separate stock items. Because no formal study had been made previously of the inventory replenishment operations, it was decided to gather some general information about order placement and receiving costs, and inventory carrying costs, and also to analyze in detail several typical items in inventory Southern had installed a small computer for maintaining inventory records, writing purchase orders, and other record keeping functions. To use this equipment, efficiently, the master inventory records were updated only once weekly. Purchase orders were also prepared and issued once a week-on Friday. The company worked a 5 day work week and operated 260 days per year. (You may make the assumption that the company will order every Friday.) The cost of preparing and processing a requisition, preparing a purchase order, and making necessary record changes was estimated to be $12.50 per order. In addition the company estimated that the cost of inspecting the incoming shipments, preparation of receiving reports, and related activities cost Southern $12.25 per order. Analysis of company records indicated that the following were reasonable estimates of the variable cost of carrying inventories (as a percentage of the dollar value of the average inventory): Cost Category % of Total Carrying Cost Capital cost Obsolescence 18 Taxes Storage & handling The Southern Hydraulic Supply Company was adistributor of hydraalic supplies nanfacture of The hydraulic items that Southern stocked were mainly used in maintenance, modification, trucks, off-highway construction equipment, and machine tools. the Gulf states area. and manufacture of Southern had grown from a small two-person operation to a $175 million per year 25 years. The growth of its dollar volume was based on an excellent reputation for good general expansion of the industry in the Gulf stales Prom its inception Southern had been a business in a span of in sound financial condition. profitable business Despite the continued growth of profits in absolute terms, however, Southern found that profits asa When management became of policies and procedures percentage of sales had declined from 11.3 percent of sales to 6.4 percent of sales aware of the seriousness of the problem, it was decided to undertake a thorough review in the areas that could have significant influence on costs and profits-namely, product lnempany force, and inventory replenishment. The last area was included as a major area had been experiencing increasing difficulty with out-of-stock situations. line, sales methods, labor for study because Inventory Replenishment Procedures Up until the time that the review of the inventory replenishment policies and procedures were begun, there had been no formal study of this phase of the company's operations the company's major functions, Since maintaining inventories was one of always used experienced personnel to control the placing of orders correct decisions. However, the inventory replenishment problem had Southern had and had relied on their judgment to make become vastly more complicated in recent years as the variety ofitems carried had tripled to now including 15,000 separate stock items. Because no formal study had been made previously of the inventory replenishment operations, it was decided to gather some general information about order placement and receiving costs, and inventory carrying costs, and also to analyze in detail several typical items in inventory Southern had installed a small computer for maintaining inventory records, writing purchase orders, and other record keeping functions. To use this equipment, efficiently, the master inventory records were updated only once weekly. Purchase orders were also prepared and issued once a week-on Friday. The company worked a 5 day work week and operated 260 days per year. (You may make the assumption that the company will order every Friday.) The cost of preparing and processing a requisition, preparing a purchase order, and making necessary record changes was estimated to be $12.50 per order. In addition the company estimated that the cost of inspecting the incoming shipments, preparation of receiving reports, and related activities cost Southern $12.25 per order. Analysis of company records indicated that the following were reasonable estimates of the variable cost of carrying inventories (as a percentage of the dollar value of the average inventory): Cost Category % of Total Carrying Cost Capital cost Obsolescence 18 Taxes Storage & handling