Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The timing of the stages in the ean manufacturing process can vary depending on a number of factors, but a general order is as follows:

The timing of the stages in the ean manufacturing process can vary depending on a number of factors, but a general order is as follows:

Design and Mold Preparation:

Duration: Can vary from a few weeks to a few months, depending on design complexity and detail.

Fabric Selection:

Duration: A few weeks, depending on fabric suppliers and order volume.

Cut:

Duration: A few days to a week, considering the level of automation and production scale.

Marking and Packaging:

Duration: A few days to a week, in parallel with slaughtering operations.

Stitch:

Duration: A few weeks to a few months, depending on production scale and complexity.

Quality Control

(

In Sewing Process

)

:

Duration: A few days to a week, parallel to the sewing operations.

Assembly and Compatibility:

Duration: A few days to a week, in parallel with sewing and quality control operations.

Final Stitching and Leg Arrangement:

Duration: A few days, parallel to the assembly process.

Washing and Finishing:

Duration: A few days to a week, depending on special effects and washing processes.

Quality Control

(

Final Review

)

:

Duration: A few days to a week, parallel to finishing operations.

Labeling and Packaging:

Duration: A few days to a week, in parallel with final quality control and finishing.

Storage and Distribution:

Duration: A few days to a week, depending on product quantity, warehouse capacity and distribution plans.

These times are affected by many variables and only provide a general guide. Particularly special orders, special designs or large production quantities can affect every stage in the

process

.

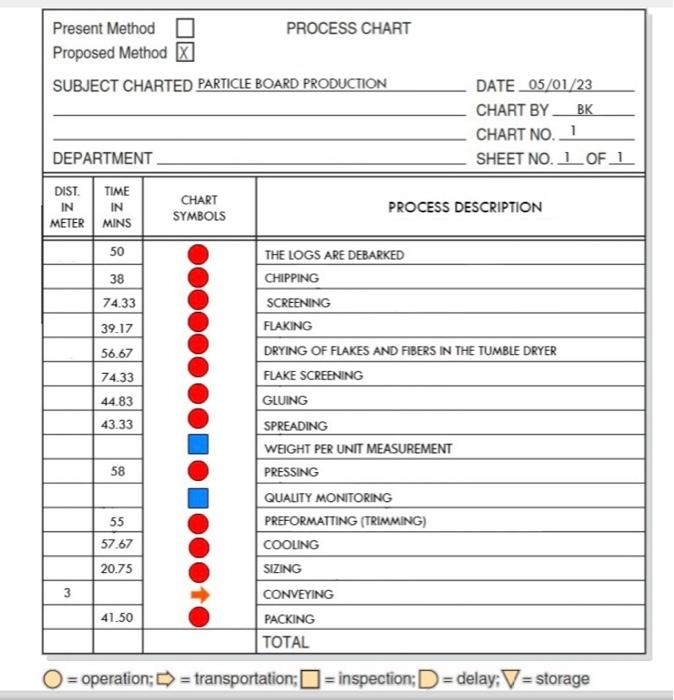

I need a process chart that includes all the steps above for a company that produces jeans.

The chart I want you to make should be a chart similar to the process chart in the photo.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started