Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The United States Aftermarket Automotive Parts and Components market is $ 1 7 . 5 billion. It is expected to reach $ 2 0 billion

The United States Aftermarket Automotive Parts and Components market is $ billion. It is expected to reach $ billion in the next five years, registering a CAGR of around during the forecast period.The automotive industry in the USA is a significant contributor to the countrys economy, with a wide variety of companies involved in manufacturing automotive parts. Ross Austin is one of the top automotive parts companies in the USA.

The State of the Auto Industry

On May President Joe Biden made the case for his $ billion electricvehicle proposal, urging automakers not to build zeroemission vehicles abroad for US consumers. The president stated, We need automakers and other companies to keep investing here in America and not take the benefits of our public investments and expand electric vehicles and battery manufacturing abroad," Biden said on a visit to a Ford Motor Co FN electricvehicle plant in Dearborn, Michigan, to see the EV version of its bestselling F pickup truck

The US Department of Energy plans to fuel the auto industrys transition to electric vehicles with $ billion in loans and grants and $ billion in loans to convert US automaker and supplier facilities into hybrid and electric vehicles manufacturing centers.The Energy Department also said it plans to invest $ billion to boost US production of advanced batteries and battery materials to support the countrys transition to electric vehicles and clean energy. The program aims to build or refurbish factories in communities with existing auto manufacturing facilities and to bolster the domestic EV supply chain.

Ross Austin Auto Technologies Companys Background

Ross Austin Auto produces headlamps, interior lighting, rear combination lamps, car body lights, sensors radar sensors battery sensors & battery management systems, converters & electronic power steering.

Ross Austin Auto was founded in by Ross Austin and His brother Robert to produce auto parts for the Detroit automakers. For the first ten years of operations, Ross Austin worked solely as an automaker subcontractor. Still, since then, it has substantially diversified to avoid the cyclical problems the auto industry faces. By this diversification attempt led RAAT to produce over items, including sensors radar sensors battery sensors & battery management systems. It also led to an increase in sales of from to As a corresponding increase in production volume and sales, RAAT spent $ to expand production facilities. The expansion increased production capacity by about Because of the increased production capacity, RAAT has made a concerted effort to attract new business and recently entered contracts with automakers to provide sensors radar sensors and batteries for electric vehicles.

Capital Budgeting Committee CBC

Over the past ten years, RAATs capitalbudgeting approach evolved into a somewhat elaborate procedure in which new proposals are categorized into profit, research and development, and safety.

Over the past several months, CBC has met monthly to consider the changes the Biden administration had proposed for the auto industry and how the company could utilize the government funding. On January the finance committee of Ross Austin Auto met to consider the changes proposed by the Energy Department and how they would affect the companys eight capitalbudgeting projects. Present at the meeting were Ross Austin, president and founder, his brother Robert Diamond, comptroller, and Chris Walken, head of research and development, who made a final judgment on all proposed capital outlays for review.

Projects falling into the profit or research and development areas are evaluated using present value techniques, using a percent cost of capital; those falling into the safety classification are evaluated in a more subjective framework. Although research and development projects must receive favorable results from the present value criteria, a total dollar limit is also assigned to projects of this category, typically running about $ million. This limitation was imposed by RAAT primarily because of the limited availability of quality researchers in the auto industry. RAAT felt that if more funds than that were allocated, we simply couldnt find the manpower to administer them properly. On the other hand, the benefits derived from safety projects are not in terms of cash flows; hence, present value methods are not used at all in their evaluation. The subjective approach used to evaluate safety projects results from the pragmatically difficult task of quantifying the benefits of these projects in dollar terms. Thus, these projects are subjectively evaluated by a managementworker committee with a limited budget. The committee agreed that all eight projects would be evaluated as research and development projects.

Project Description and Financial Information

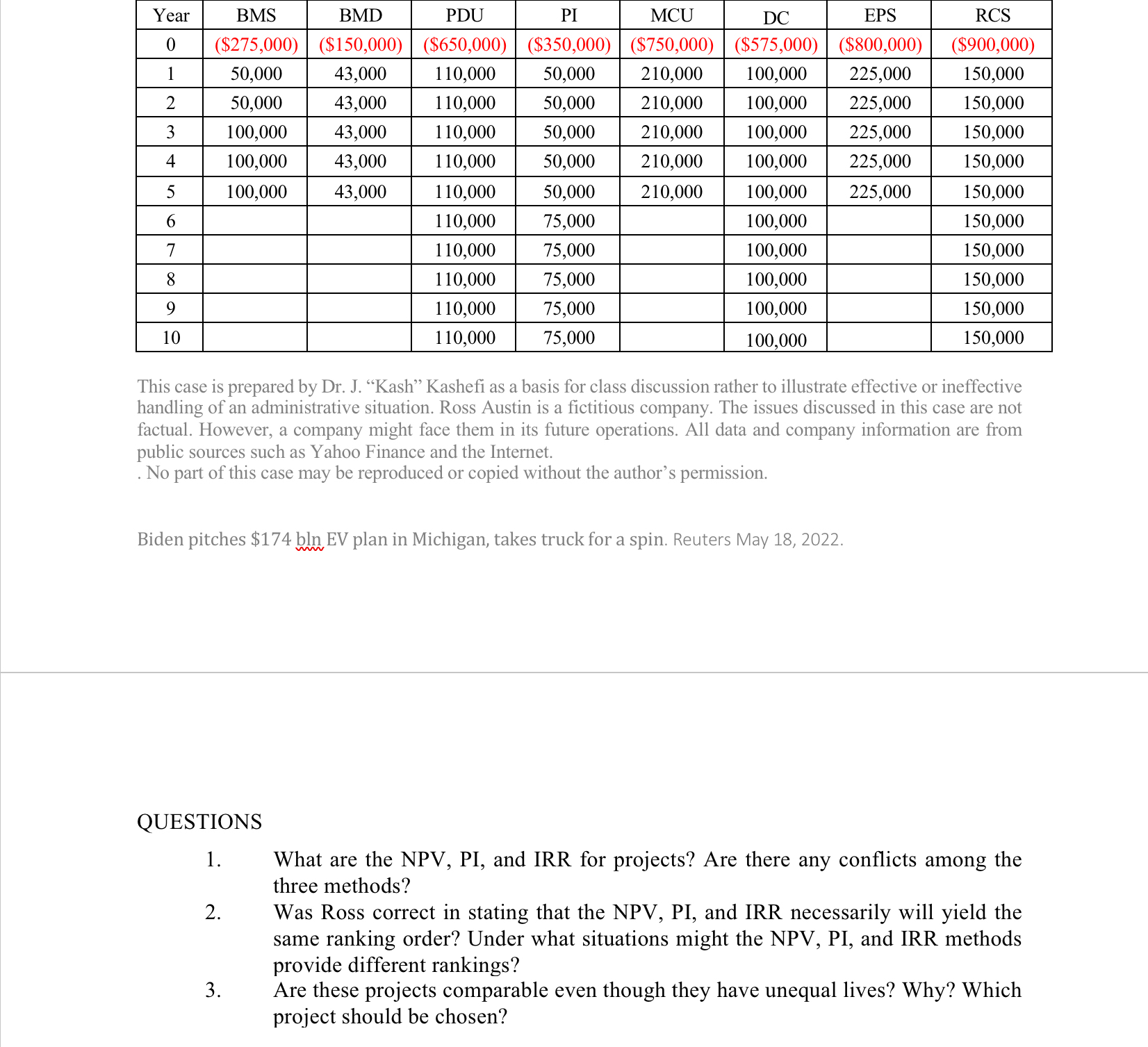

The first set of projects listed on the meetings agenda for examination involves the utilization of RAATs Senser equipment. The new suite of sensor equipment provides highaccuracy readings with lowtemperature drift in several electric vehicle applications, including Battery Management Systems BMS Power Distribution Systems PDUs and Battery Disconnect Units BDUs

The second project involves manufacturing Power Inverters PI DCDC Converters, Battery & related parts, and Motor Control Units MCU some of the other essential parts that RAAT will manufacture over time to stay relevant in the market.

The third project is lithium batteries that are built for use as house batteries in RVs Campers, Van builds, or any vehicle where you are camping or working off the grid in comfort,

Aftermarket Auto Market

The impact of the COVID pandemic on the US aftermarket automotive market was severe, and this could be attributed to several production halts in the manufacturing industry due to lockdowns and travel restrictions imposed by governments worldwide. The supply chain of the entire automotive industry was disrupted, impacting the production of automotive parts and components in the market. RAAT has decided to enter the aftermarket parts to produce remote car starters RCS and electronic power steering EPS

As the meeting opened, the debate immediately centered on the most appropriate method for evaluating all the projects. Ross suggested that, as the projects to be considered were mutually exclusive, perhaps their usual capitalbudgeting net present value criteria were inappropriate. In examining these projects, he felt they should be more concerned with relative profitability or yield. Both Robert and Chris agreed with Rosss point of view, with Chris advocating a profitability index approach and Woelk preferring the internal rate of return. Jorgensen argued that using the profitability index would provide a benefitcost ratio, directly implying relative profitability. Thus, they merely need to rank these projects and select those with the highest profitability index. Wilken agreed with Roberts point of view but suggested that calculating an internal rate of return would also give a measure of profitability and perhaps be somewhat easier to interpret. To settle the issue, Ross suggested they calculate all three measures, yielding the same ranking.

From here, the discussion turned to an appropriate approach to the problem of differing lives among projects. Walken argued that there really was not a problem here and that as all the cash flows from these projects can be determined, any of the discounted cash flow methods of capital budgeting will work well.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started