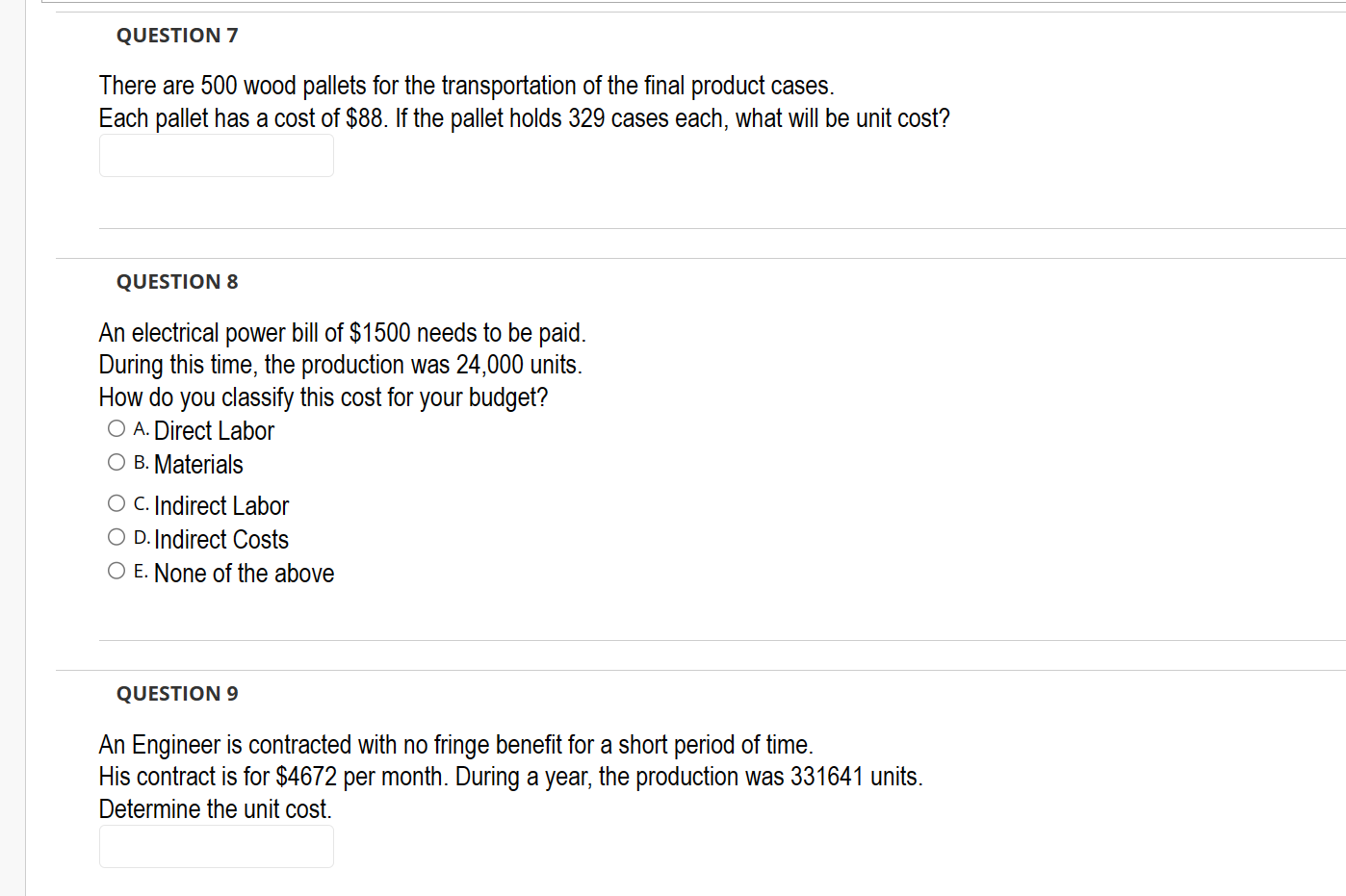

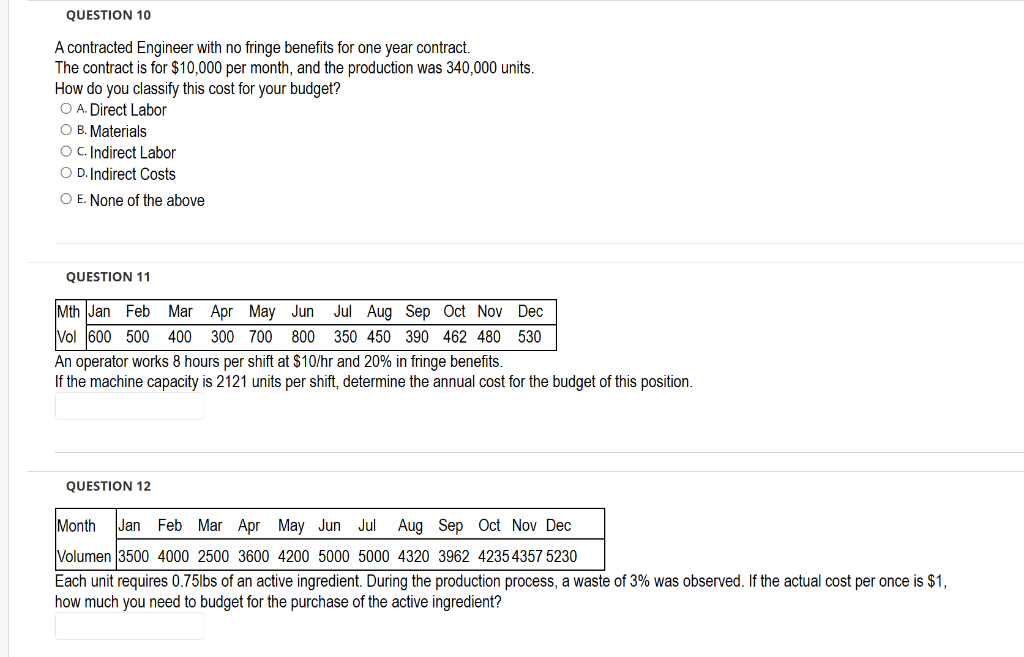

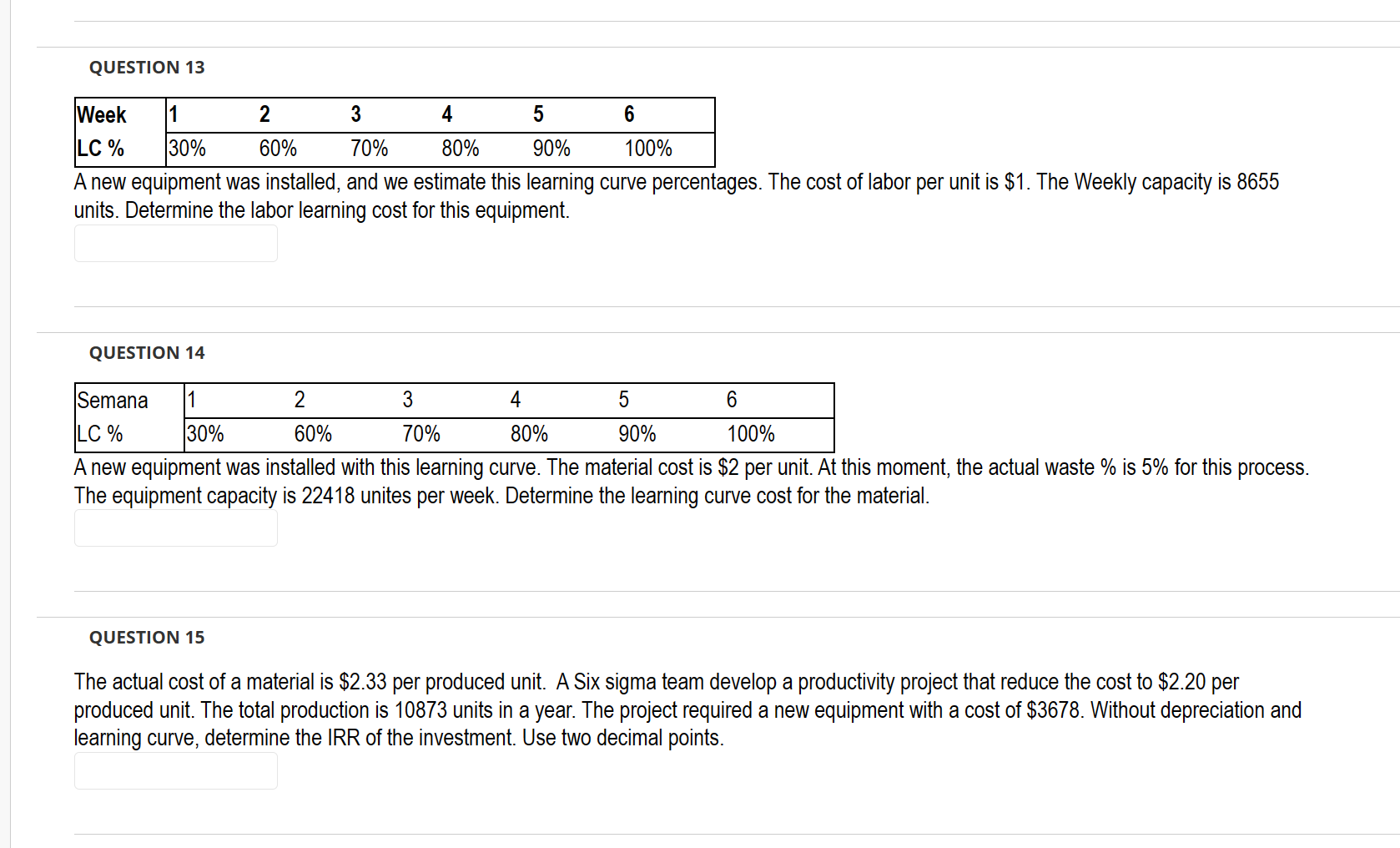

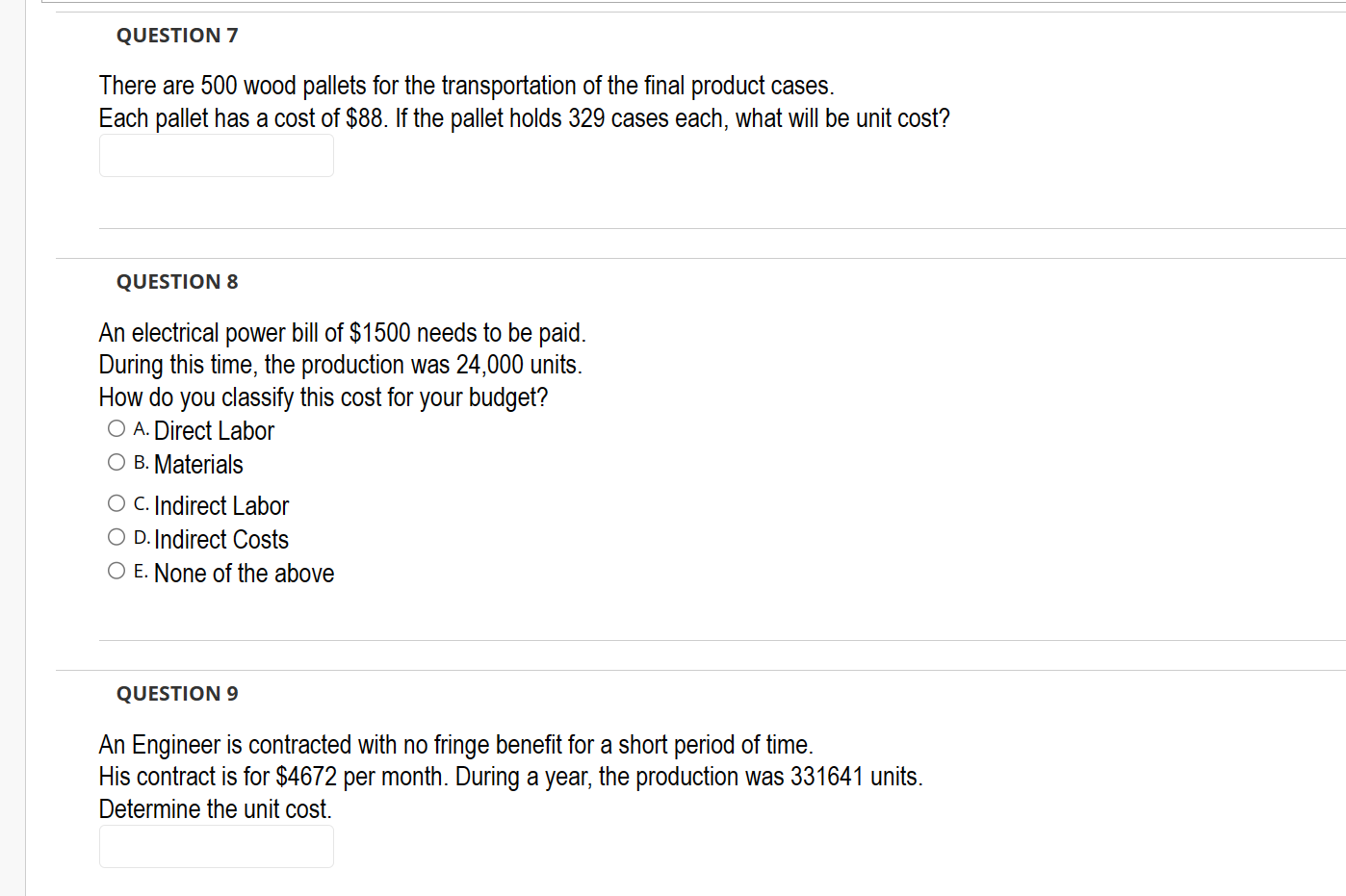

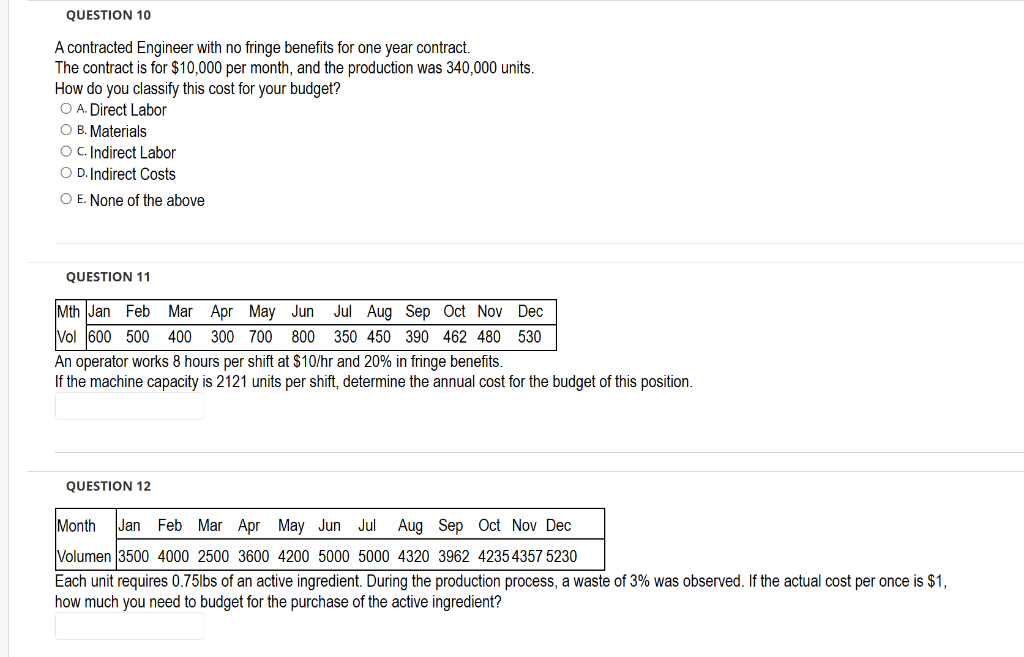

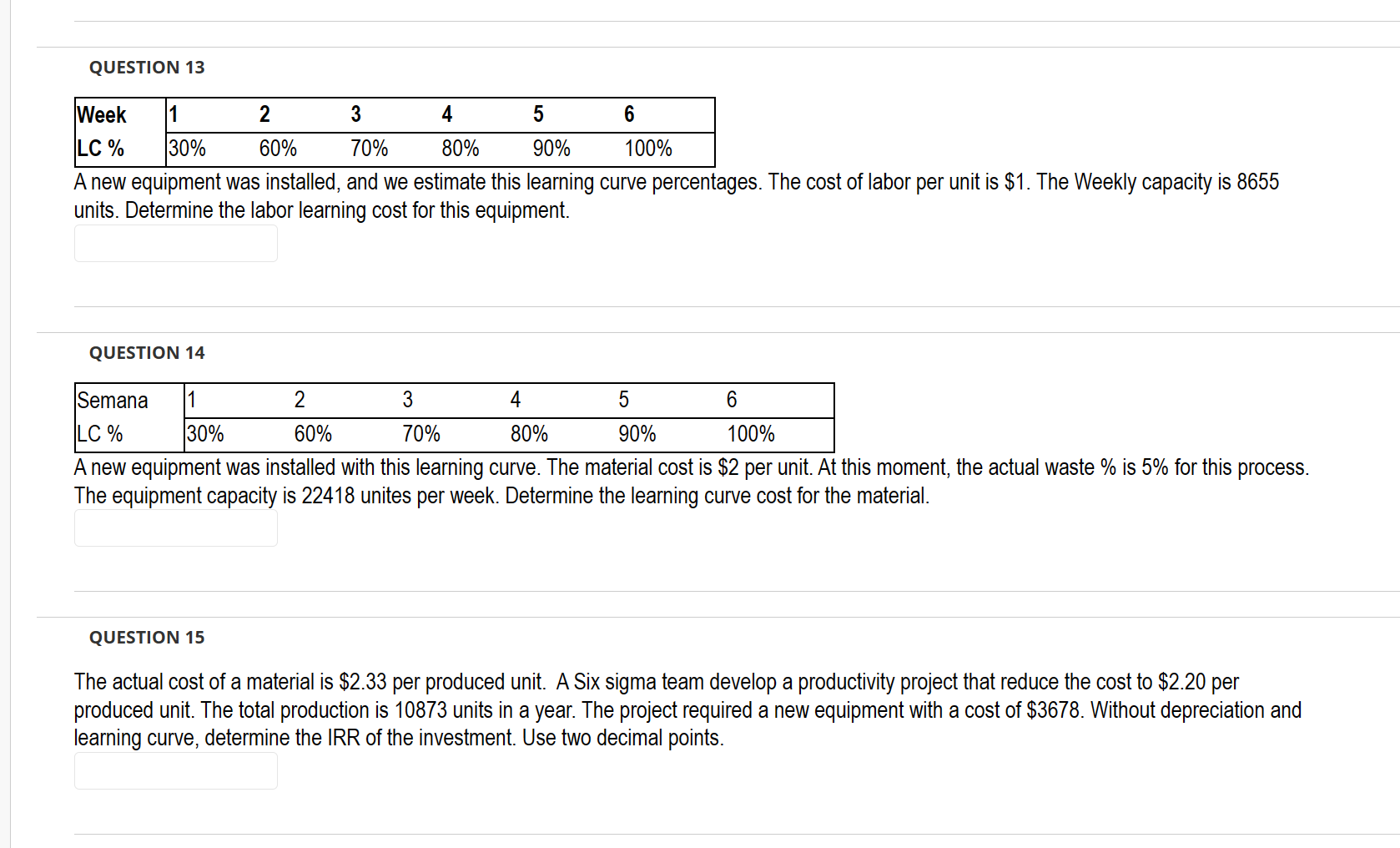

There are 500 wood pallets for the transportation of the final product cases. Each pallet has a cost of $88. If the pallet holds 329 cases each, what will be unit cost? QUESTION 8 An electrical power bill of $1500 needs to be paid. During this time, the production was 24,000 units. How do you classify this cost for your budget? A. Direct Labor B. Materials C. Indirect Labor D. Indirect Costs E. None of the above QUESTION 9 An Engineer is contracted with no fringe benefit for a short period of time. His contract is for $4672 per month. During a year, the production was 331641 units. Determine the unit cost. A contracted Engineer with no fringe benefits for one year contract. The contract is for $10,000 per month, and the production was 340,000 units. How do you classify this cost for your budget? A. Direct Labor B. Materials C. Indirect Labor D. Indirect Costs E. None of the above QUESTION 11 An operator works 8 hours per shift at $10/hr and 20% in fringe benefits. If the machine capacity is 2121 units per shift, determine the annual cost for the budget of this position. QUESTION 12 Each unit requires 0.75lbs of an active ingredient. During the production process, a waste of 3% was observed. If the actual cost per once is $1, how much you need to budget for the purchase of the active ingredient? QUESTION 13 A new equipment was installed, and we estimate this learning curve percentages. The cost of labor per unit is $1. The Weekly capacity is 8655 units. Determine the labor learning cost for this equipment. QUESTION 14 A new equipment was installed with this learning curve. The material cost is $2 per unit. At this moment, the actual waste % is 5% for this process. The equipment capacity is 22418 unites per week. Determine the learning curve cost for the material. QUESTION 15 The actual cost of a material is $2.33 per produced unit. A Six sigma team develop a productivity project that reduce the cost to $2.20 per produced unit. The total production is 10873 units in a year. The project required a new equipment with a cost of $3678. Without depreciation and learning curve, determine the IRR of the investment. Use two decimal points. There are 500 wood pallets for the transportation of the final product cases. Each pallet has a cost of $88. If the pallet holds 329 cases each, what will be unit cost? QUESTION 8 An electrical power bill of $1500 needs to be paid. During this time, the production was 24,000 units. How do you classify this cost for your budget? A. Direct Labor B. Materials C. Indirect Labor D. Indirect Costs E. None of the above QUESTION 9 An Engineer is contracted with no fringe benefit for a short period of time. His contract is for $4672 per month. During a year, the production was 331641 units. Determine the unit cost. A contracted Engineer with no fringe benefits for one year contract. The contract is for $10,000 per month, and the production was 340,000 units. How do you classify this cost for your budget? A. Direct Labor B. Materials C. Indirect Labor D. Indirect Costs E. None of the above QUESTION 11 An operator works 8 hours per shift at $10/hr and 20% in fringe benefits. If the machine capacity is 2121 units per shift, determine the annual cost for the budget of this position. QUESTION 12 Each unit requires 0.75lbs of an active ingredient. During the production process, a waste of 3% was observed. If the actual cost per once is $1, how much you need to budget for the purchase of the active ingredient? QUESTION 13 A new equipment was installed, and we estimate this learning curve percentages. The cost of labor per unit is $1. The Weekly capacity is 8655 units. Determine the labor learning cost for this equipment. QUESTION 14 A new equipment was installed with this learning curve. The material cost is $2 per unit. At this moment, the actual waste % is 5% for this process. The equipment capacity is 22418 unites per week. Determine the learning curve cost for the material. QUESTION 15 The actual cost of a material is $2.33 per produced unit. A Six sigma team develop a productivity project that reduce the cost to $2.20 per produced unit. The total production is 10873 units in a year. The project required a new equipment with a cost of $3678. Without depreciation and learning curve, determine the IRR of the investment. Use two decimal points