Answered step by step

Verified Expert Solution

Question

1 Approved Answer

This has been calculated before, but done incorrectly 2.) A 180kg ingot is to be processed and cut into wafers with a final diameter of

This has been calculated before, but done incorrectly

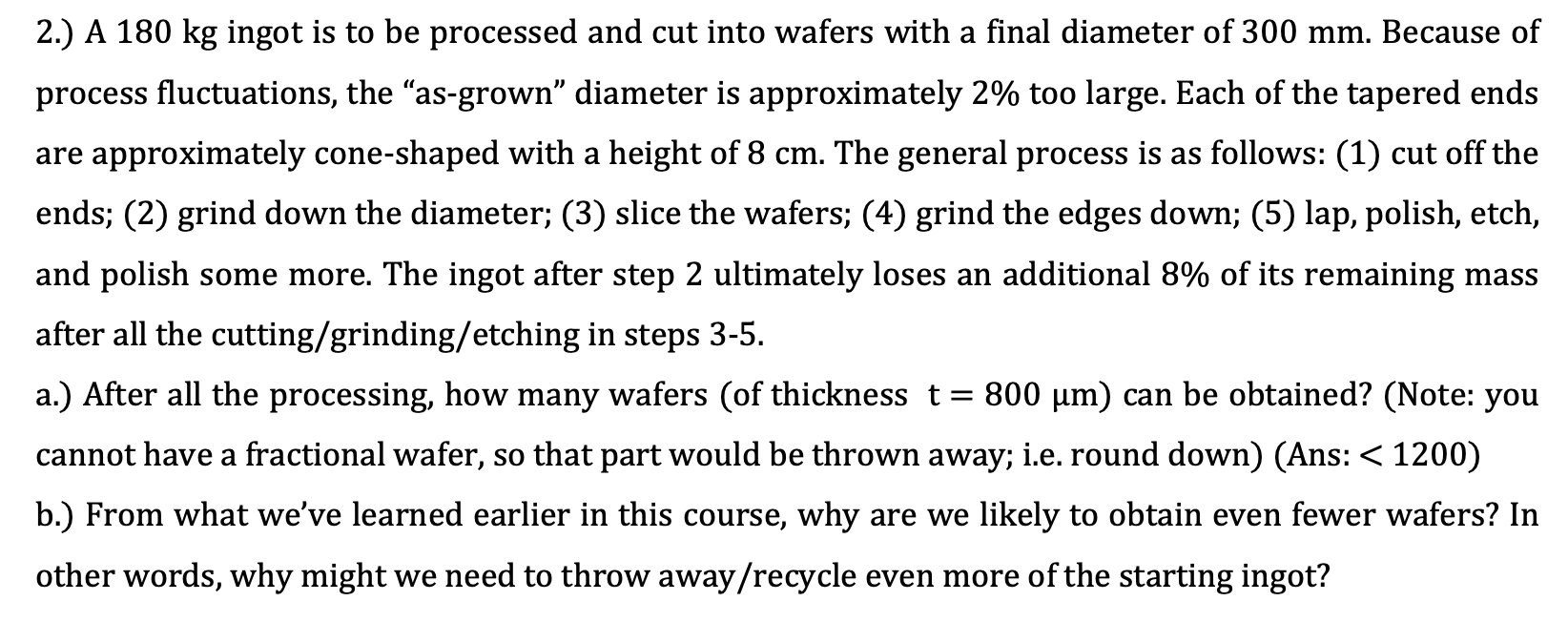

2.) A 180kg ingot is to be processed and cut into wafers with a final diameter of 300mm. Because of process fluctuations, the "as-grown" diameter is approximately 2% too large. Each of the tapered ends are approximately cone-shaped with a height of 8cm. The general process is as follows: (1) cut off the ends; (2) grind down the diameter; (3) slice the wafers; (4) grind the edges down; (5) lap, polish, etch, and polish some more. The ingot after step 2 ultimately loses an additional 8% of its remaining mass after all the cutting/grinding/etching in steps 3-5. a.) After all the processing, how many wafers (of thickness t=800m ) can be obtained? (Note: you cannot have a fractional wafer, so that part would be thrown away; i.e. round down) (Ans:

2.) A 180kg ingot is to be processed and cut into wafers with a final diameter of 300mm. Because of process fluctuations, the "as-grown" diameter is approximately 2% too large. Each of the tapered ends are approximately cone-shaped with a height of 8cm. The general process is as follows: (1) cut off the ends; (2) grind down the diameter; (3) slice the wafers; (4) grind the edges down; (5) lap, polish, etch, and polish some more. The ingot after step 2 ultimately loses an additional 8% of its remaining mass after all the cutting/grinding/etching in steps 3-5. a.) After all the processing, how many wafers (of thickness t=800m ) can be obtained? (Note: you cannot have a fractional wafer, so that part would be thrown away; i.e. round down) (Ans: Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started