Answered step by step

Verified Expert Solution

Question

1 Approved Answer

This is a design problem, there are many acceptable designs. Derive the axial shaft layout from figure 7-12. Design for stress & Choose three critical

This is a design problem, there are many acceptable designs.

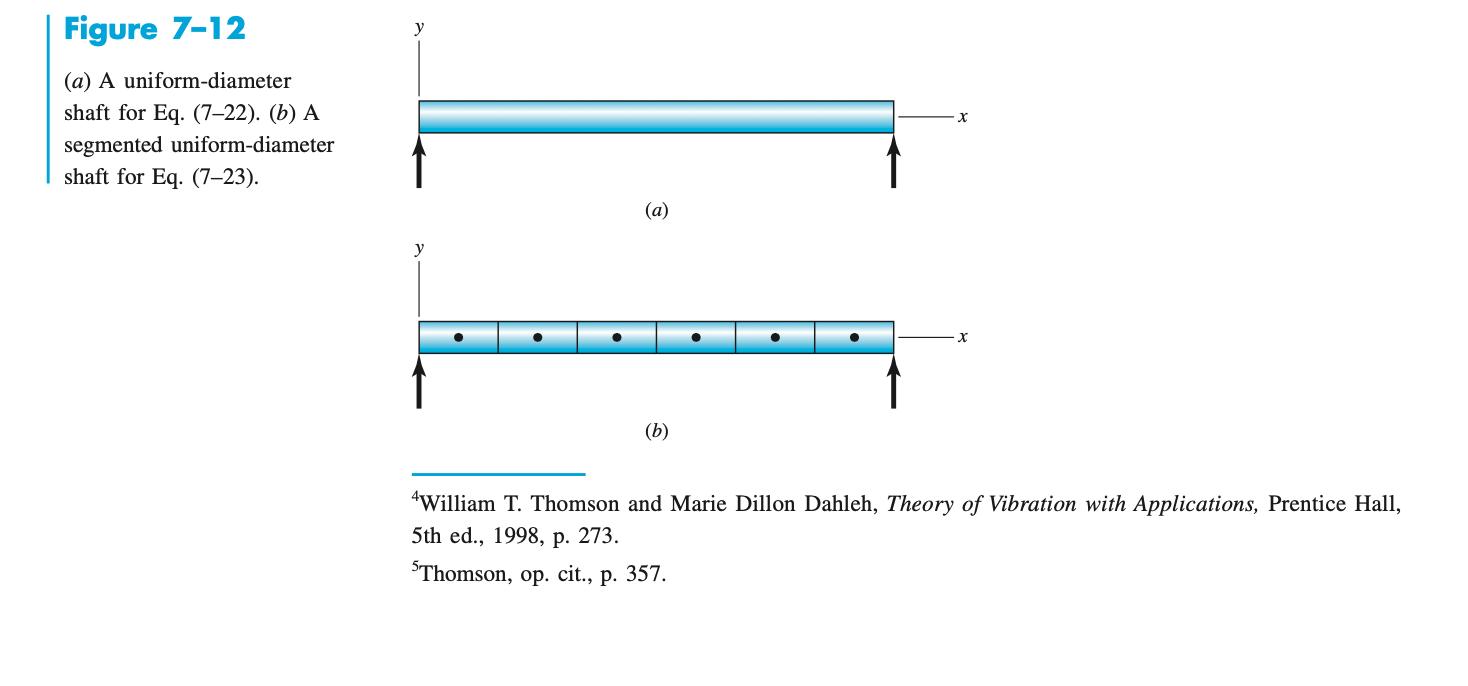

Derive the axial shaft layout from figure 7-12.

Design for stress & Choose three critical locations (e.g shoulders, keyways, and grooves etc, depending on the shaft layout one designs). Design shaft diameter and verify the factor of safety for fatigue and yielding for each critical location.

Do force analysis to figure out the supporting forces at the bearings, and the shear force and bending moment diagrams.

Check and adjust for deflection.

Draw resulting shaft design in CAD.

Figure 7-12 (a) A uniform-diameter shaft for Eq. (7-22). (b) A segmented uniform-diameter shaft for Eq. (7-23). y y (a) (b) X X William T. Thomson and Marie Dillon Dahleh, Theory of Vibration with Applications, Prentice Hall, 5th ed., 1998, p. 273. 5Thomson, op. cit., p. 357.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Shear force and bending moment are related ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started