Answered step by step

Verified Expert Solution

Question

1 Approved Answer

THIS IS FACILITY LAYOUT AND MATERIAL HANDLING Question 2[58.5=29] You are planning a warehouse to store parts of a trolley you are manufacturing for a

THIS IS FACILITY LAYOUT AND MATERIAL HANDLING

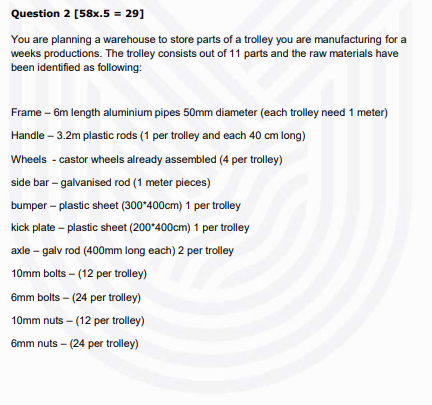

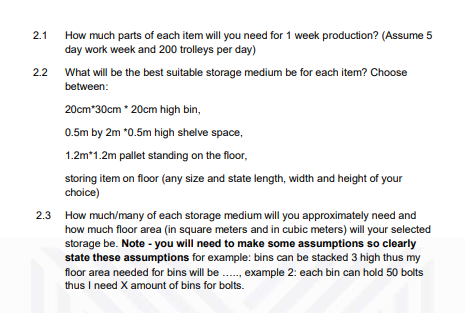

Question 2[58.5=29] You are planning a warehouse to store parts of a trolley you are manufacturing for a weeks productions. The trolley consists out of 11 parts and the raw materials have been identified as following: Frame 6m length aluminium pipes 50mm diameter (each trolley need 1 meter) Handle 3.2m plastic rods ( 1 per trolley and each 40cm long) Wheels - castor wheels already assembled (4 per trolley) side bar - galvanised rod (1 meter pieces) bumper - plastic sheet (300400cm)1 per trolley kick plate - plastic sheet (200400cm)1 per trolley axle - galv rod ( 400mm long each) 2 per trolley 10mm bolts - (12 per trolley) 6mm bolts - (24 per trolley) 10mm nuts - (12 per trolley) 6mm nuts - (24 per trolley) 2.1 How much parts of each item will you need for 1 week production? (Assume 5 day work week and 200 trolleys per day) 2.2 What will be the best suitable storage medium be for each item? Choose between: 20cm30cm20cm high bin, 0.5m by 2m0.5m high shelve space, 1.2m1.2m pallet standing on the floor, storing item on floor (any size and state length, width and height of your choice) 2.3 How much/many of each storage medium will you approximately need and how much floor area (in square meters and in cubic meters) will your selected storage be. Note - you will need to make some assumptions so clearly state these assumptions for example: bins can be stacked 3 high thus my floor area needed for bins will be ....., example 2: each bin can hold 50 bolts thus I need X amount of bins for bolts. XYZ manufacture trolleys and the following information could be deduced from its route sheets: Part 1 RACDF quantity 500 Part 2 RADBF quantity 1500 Part 3 RBEDF quantity 2500 Part 4 RACDBF quantity 7500 Part 5 RBCF quantity 1500 Page 3 of 4 It must also be noted that department D is painting and department C is welding and they should not be next to each other. 3.1 Construct a From-To chart from the information provided. 3.2 Based on your From-To chart conduct a Pareto analysis and use this analysis (as well as additional information provided) to rate relationships (AEIOUX) and then construct a dimensionless layout for the departments used in the route sheets. Question 2[58.5=29] You are planning a warehouse to store parts of a trolley you are manufacturing for a weeks productions. The trolley consists out of 11 parts and the raw materials have been identified as following: Frame 6m length aluminium pipes 50mm diameter (each trolley need 1 meter) Handle 3.2m plastic rods ( 1 per trolley and each 40cm long) Wheels - castor wheels already assembled (4 per trolley) side bar - galvanised rod (1 meter pieces) bumper - plastic sheet (300400cm)1 per trolley kick plate - plastic sheet (200400cm)1 per trolley axle - galv rod ( 400mm long each) 2 per trolley 10mm bolts - (12 per trolley) 6mm bolts - (24 per trolley) 10mm nuts - (12 per trolley) 6mm nuts - (24 per trolley) 2.1 How much parts of each item will you need for 1 week production? (Assume 5 day work week and 200 trolleys per day) 2.2 What will be the best suitable storage medium be for each item? Choose between: 20cm30cm20cm high bin, 0.5m by 2m0.5m high shelve space, 1.2m1.2m pallet standing on the floor, storing item on floor (any size and state length, width and height of your choice) 2.3 How much/many of each storage medium will you approximately need and how much floor area (in square meters and in cubic meters) will your selected storage be. Note - you will need to make some assumptions so clearly state these assumptions for example: bins can be stacked 3 high thus my floor area needed for bins will be ....., example 2: each bin can hold 50 bolts thus I need X amount of bins for bolts. XYZ manufacture trolleys and the following information could be deduced from its route sheets: Part 1 RACDF quantity 500 Part 2 RADBF quantity 1500 Part 3 RBEDF quantity 2500 Part 4 RACDBF quantity 7500 Part 5 RBCF quantity 1500 Page 3 of 4 It must also be noted that department D is painting and department C is welding and they should not be next to each other. 3.1 Construct a From-To chart from the information provided. 3.2 Based on your From-To chart conduct a Pareto analysis and use this analysis (as well as additional information provided) to rate relationships (AEIOUX) and then construct a dimensionless layout for the departments used in the route sheetsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started