Question

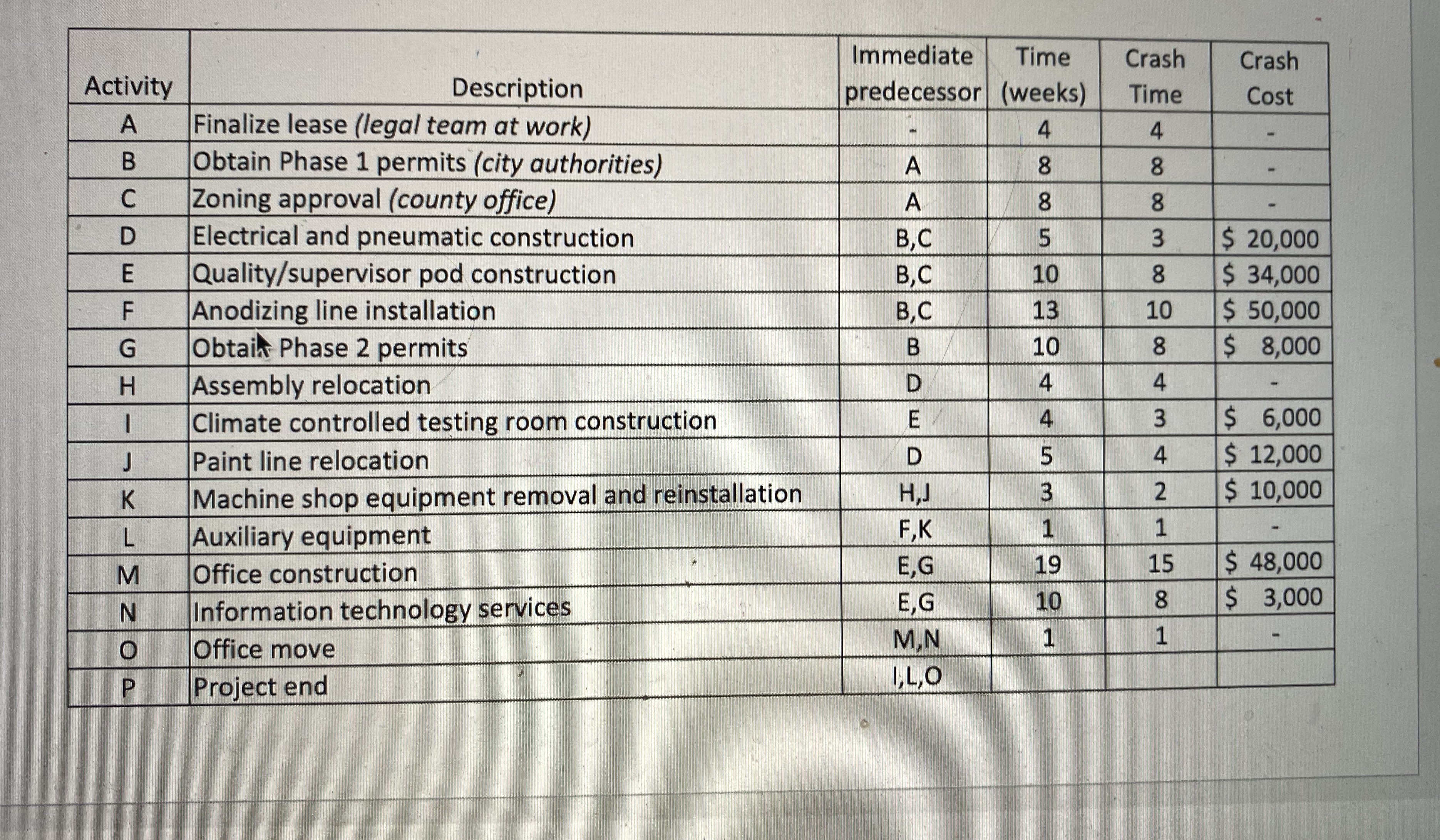

This question is adapted from Project Destiny by Mark & Johnson ( Case #9B19D005 ). RL Company produces standardized and customized natural gas meters and

This question is adapted from Project Destiny by Mark & Johnson ( Case #9B19D005 ). RL Company produces standardized and customized natural gas meters and electric instruments for customers globally . The typical process involves machining , anodizing , assembly , and testing . Based on projected growth , RLC has decided to lease and move into a larger facility . The planned layout in this new facility will improve material flow . This move is critical because RLC cannot stop supplying products to its customers while the transition happens . For example , it will need to stock higher levels of work -in-process inventory because components produced by Machine A have to be available for Machine B to continue production while Machine A is moved , and so on. It is currently April , and RLC's current lease expires at the end of the year (in weeks ). However , they want to move all their equipment to the new facility before the Christmas break , which gives them 34 weeks for the relocation The attached table shows the activities you plan to undertake as the operations manager . You need to be sure you can complete the project in 34 weeks . Based on large capital expenditure the company has incurred , you are allowed no more than $90,000 in additional funds . Assume that the standard deviation of your expected project duration is weeks . What will you say to the CEO and CFO in your first project meeting scheduled with them this afternoon ?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started