Question: Tim OHare is the distribution manager for Complete Hardware Supply (CHS). with headquarters in Cleveland, Ohio. Consolidated Inc a holding company, recently acquired CHS. Consolidated's

Tim OHare is the distribution manager for Complete Hardware Supply (CHS). with headquarters in Cleveland, Ohio. Consolidated Inc a holding company, recently acquired CHS. Consolidated's management has insisted that tighter control procedures be instituted to limit inventory investment at CHS.

CHS is a distributor of various hardware items to local hardware stores in the northeastern Ohio area. It purchases a wide variety of hardware items from a number of vendors located throughout the country. Hardware store orders are filled from the inventories held at CHS's Cleveland warehouse. Historically, Tam his used a reorder point method of inventory control to determine reorder quantities acquired from vendors and to control inventory levels.

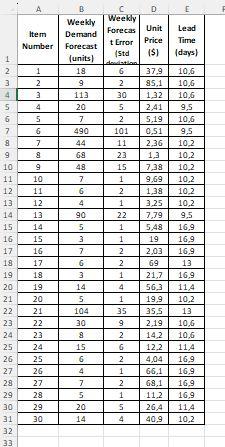

To deal with the new investment limit plated on inventories, Tins selects for analysis 30 representative items from 500 in the product line. He collected the data on demand, product value, and lead times as shown in Fig. I.

The cost for preparing and transmitting a purchase order is $15, and each item is purchased from a separate vendor on a separate order. The company's annual inventory-carrying cost is 25 percent, or 0.0048 per week. Tim currently uses a 98 percent in-stock probability during the lead time as a control on customer services, which was set in consultation with the companys salespersons.

The lead time to receive a replenishment order is composed of three elements: (1) the time to prepare and transmit an order. (2) the time to fill the order at the vendor location, and (3) the time to transport the order to Cleveland. Currently, orders are prepared by hand and mailed to vendors, a system where preparation takes two days and transmittal takes two days. Trucking is used to transport products to CHS. It takes approximately one day to transport product for every 300 miles of distance. Vendor order filling requires five working days.

Prorating the restrictions that Consolidated has placed on all items, the total investment for these 30 items should not exceed $18,000. However, to maintain revenues, Tim would like to have no more stockouts per year than he currently is experiencing.

Please, carefully read the case study below (You will find the related data on Project Data

(Figure 1).xlsx file.) What course of action should Tim take, and how should he argue his case to the holding management?

Considering data and parameters, calculate all related inventory management variables

(Average demand during lead time, safety stock, reorder level, order quantity, average

inventory level, and holding, ordering, and total costs) with respect to Tims inventory method.

(Be careful about the consistency of time intervals of data and parameters.)

Briefly sum up the current situation. Use the suitable variable(s) as a metric of the

inventory system.

Analyze and evaluate each improvement option with respect to the selected metric(s).

Considering three options and the total investment budget, make your decision (none of

them, a single option, or their combinations). Then, state your final improvement decision with its reasons. (Make Tim ready to argue his case to the management.)

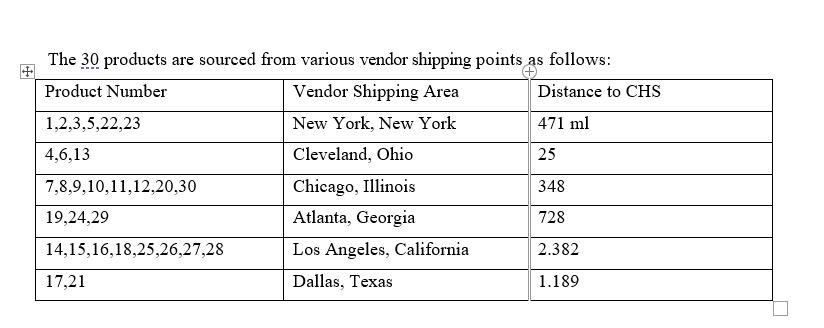

The 30 products are sourced from various vendor shipping points as follows

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts