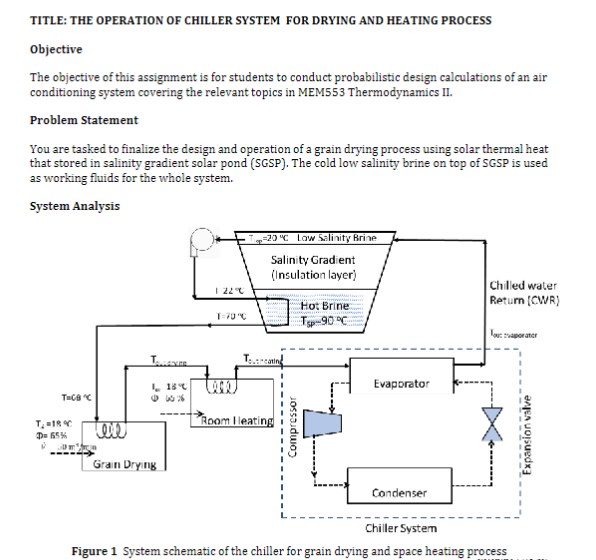

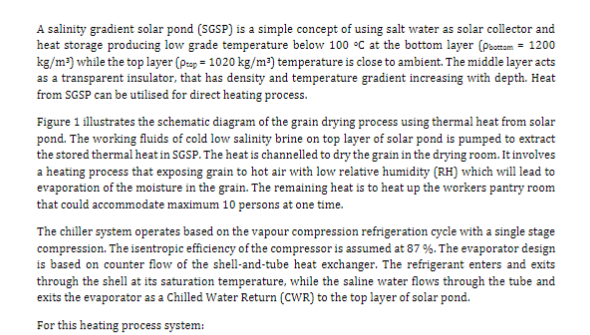

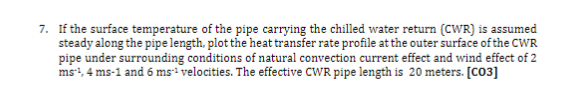

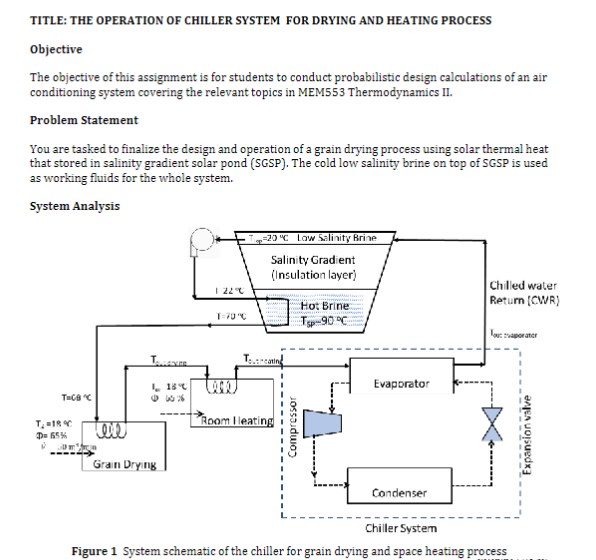

TITLE: THE OPERATION OF CHILLER SYSTEM FOR DRYING AND HEATING PROCESS Objective The objective of this assignment is for students to conduct probabilistic design calculations of an air conditioning system covering the relevant topics in MEM553 Thermodynamics II. Problem Statement You are tasked to finalize the design and operation of a grain drying process using solar thermal heat that stored in salinity gradient solar pond (SGSP). The cold low salinity brine on top of SGSP is used as working fluids for the whole system. System Analysis Figure 1 System schematic of the chiller for grain drying and space heating process A salinity gradient solar pond (SGSP) is a simple concept of using salt water as solar collector and heat storage producing low grade temperature below 100C at the bottom layer (botam=1200 kg/m3) while the top layer (tap=1020kg/m3) temperature is close to ambient. The middle layer acts as a transparent insulator, that has density and temperature gradient increasing with depth. Heat from SGSP can be utilised for direct heating process. Figure 1 illustrates the schematic diagram of the grain drying process using thermal heat from solar pond. The working fluids of cold low salinity brine on top layer of solar pond is pumped to extract the stored thermal heat in SGSP. The heat is channelled to dry the grain in the drying room. It involves a heating process that exposing grain to hot air with low relative humidity (RH) which will lead to evaporation of the moisture in the grain. The remaining heat is to heat up the workers pantry room that could accommodate maximum 10 persons at one time. The chiller system operates based on the vapour compression refrigeration cycle with a single stage compression. The isentropic efficiency of the compressor is assumed at 87%. The evaporator design is based on counter flow of the shell-and-tube heat exchanger. The refrigerant enters and exits through the shell at its saturation temperature, while the saline water flows through the tube and exits the evaporator as a Chilled Water Return (CWR) to the top layer of solar pond. For this heating process system: If the surface temperature of the pipe carrying the chilled water return (CWR) is assumed steady along the pipe length, plot the heat transfer rate profile at the outer surface of the CWR pipe under surrounding conditions of natural convection current effect and wind effect of 2 ms1,4ms1 and 6ms1 velocities. The effective CWR pipe length is 20 meters. [CO3]