Answered step by step

Verified Expert Solution

Question

1 Approved Answer

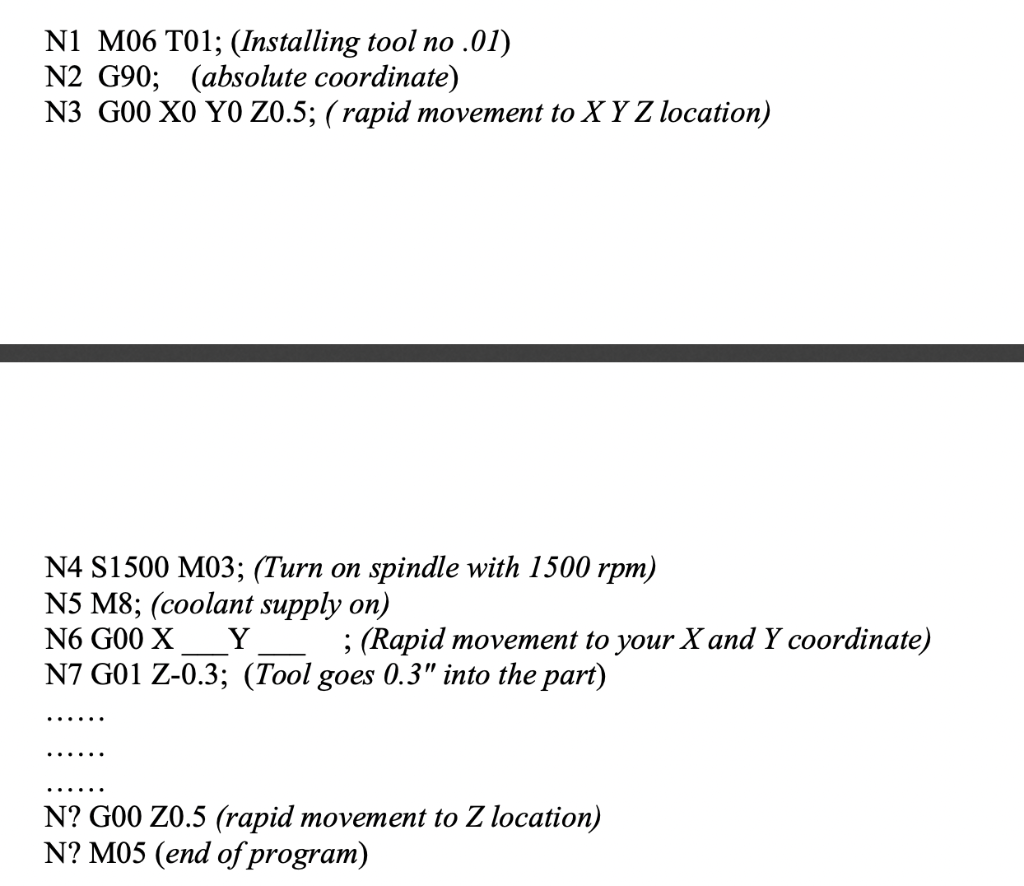

To make sure that all the programs start the same, the first and last lines are given. You will not need to define any feed

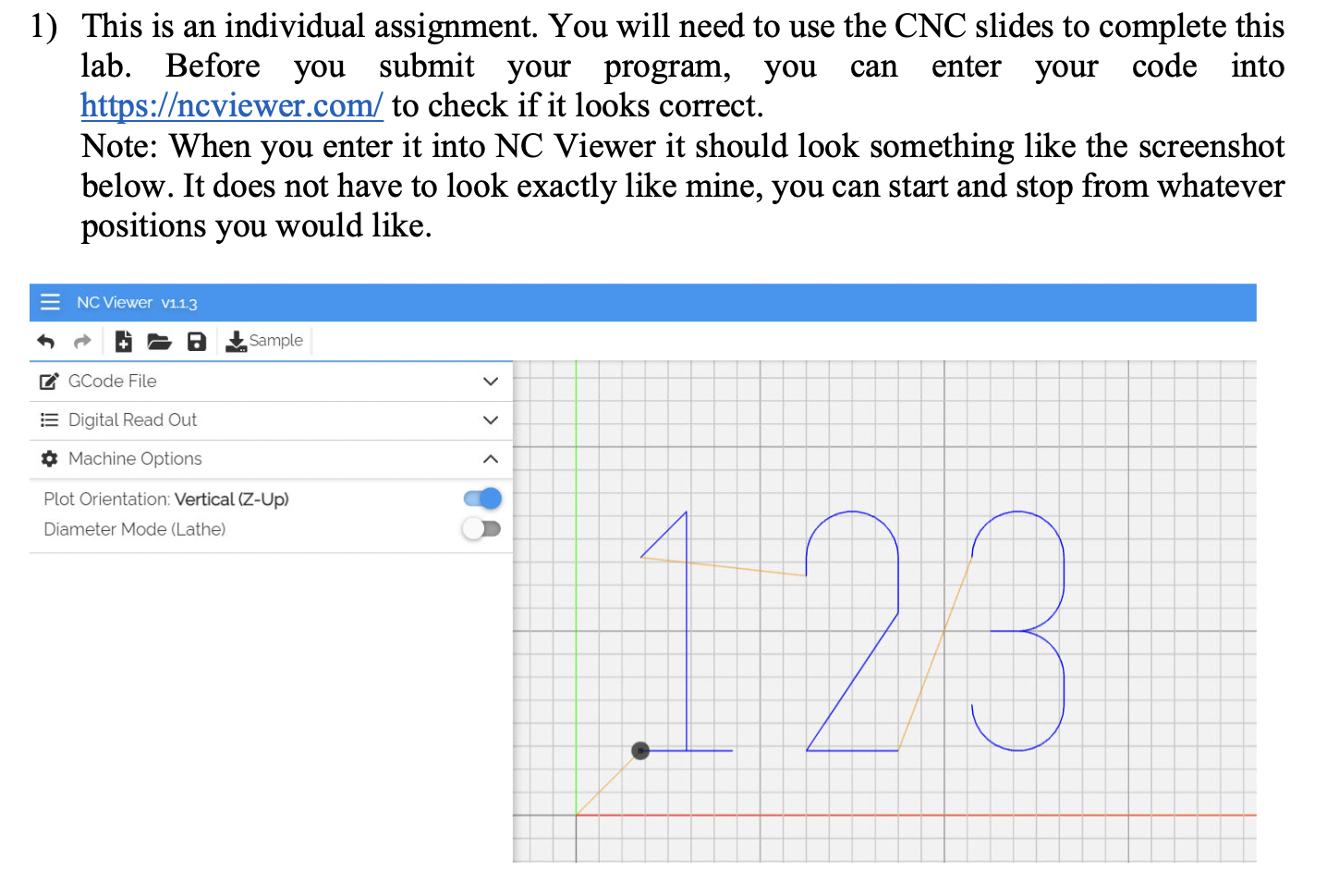

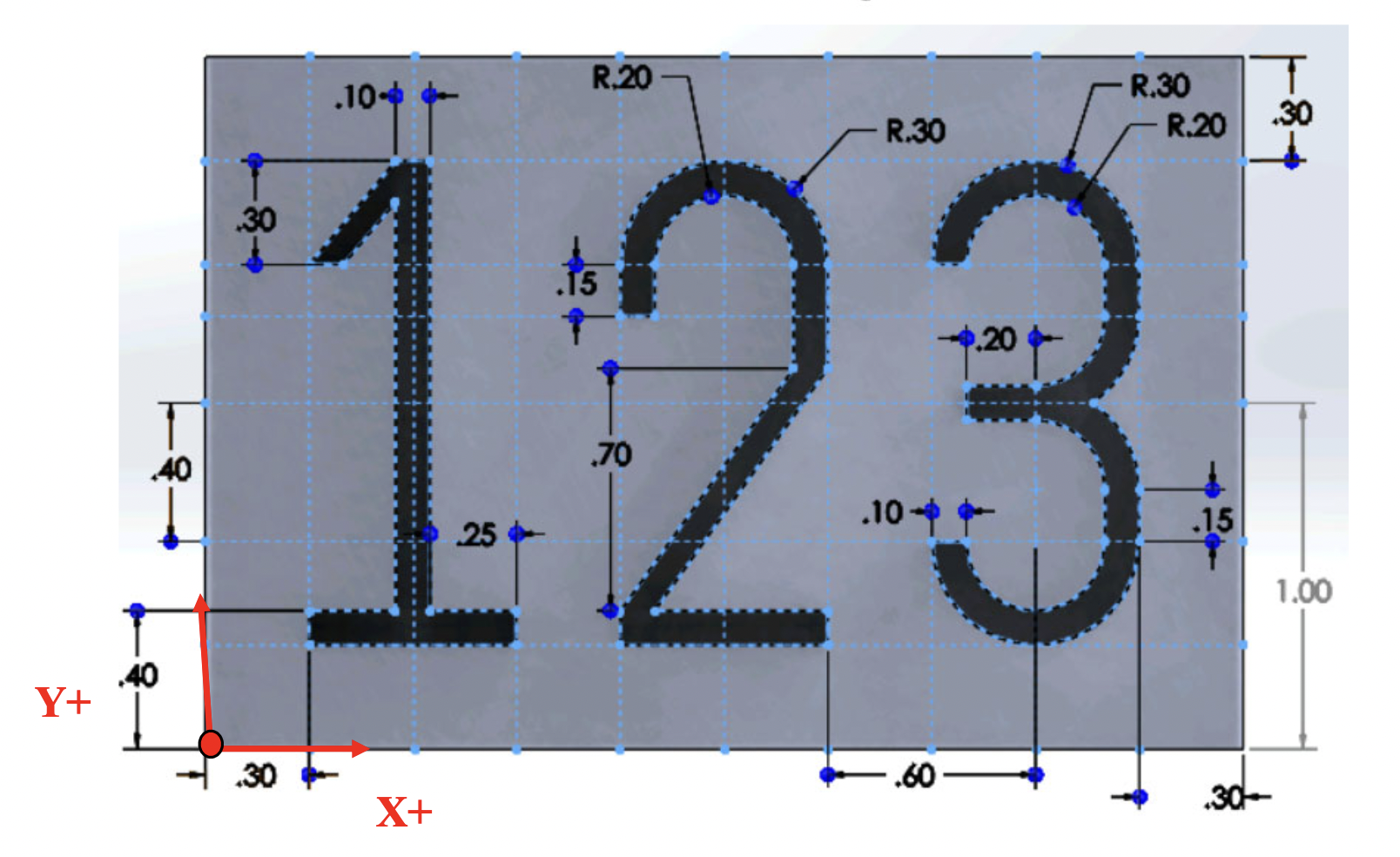

To make sure that all the programs start the same, the first and last lines are given. You will not need to define any feed (F) for any of the program. You will need to fill in the values for X and Y on N6 (line 6). and continue your program after N7 (line 7). You are free to use absolute or incremental ( or both ) coordinate in the main body of your program.

Please upload step by step and what should I exactly put into the program so it works. If its done perfectly I will rate! Thanks so much.

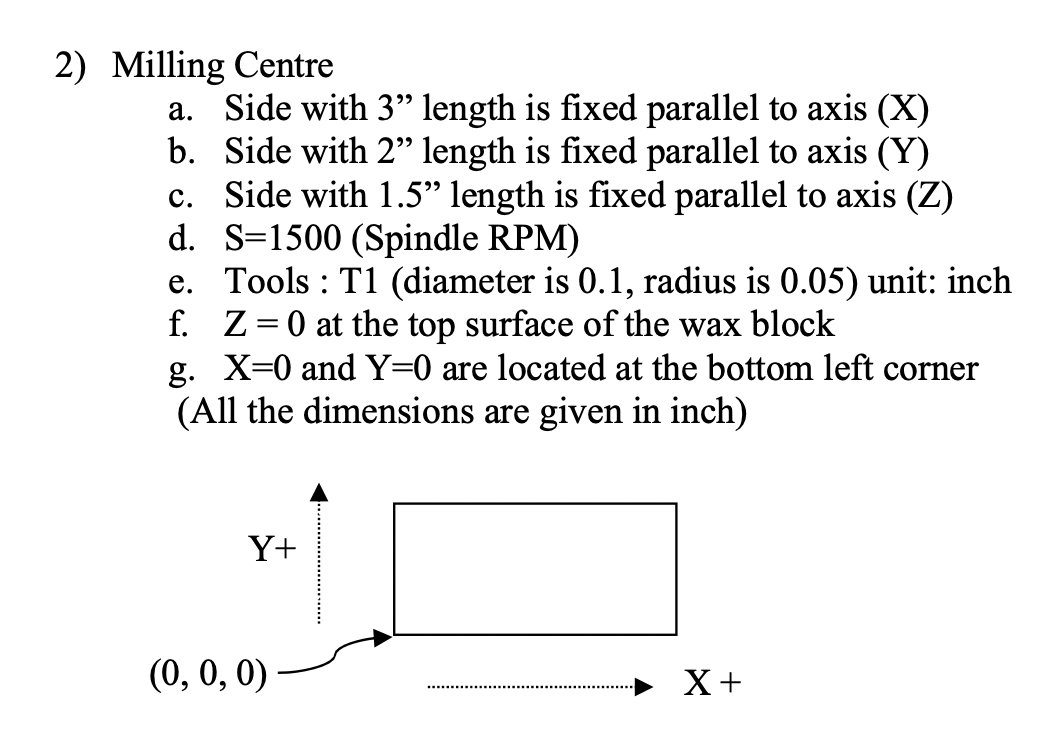

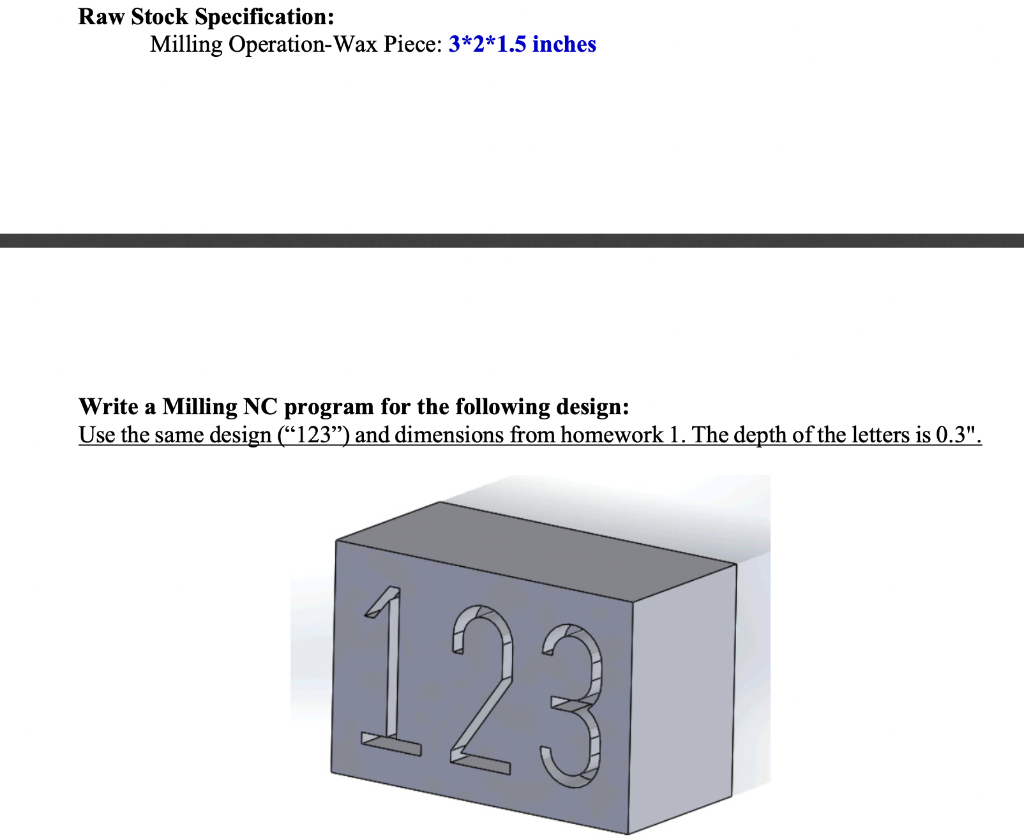

can 1) This is an individual assignment. You will need to use the CNC slides to complete this lab. Before you submit your program, you enter your code into https:/cviewer.com/ to check if it looks correct. Note: When you enter it into NC Viewer it should look something like the screenshot below. It does not have to look exactly like mine, you can start and stop from whatever positions you would like. TIL NC Viewer v1.1.3 Sample C GCode File S Digital Read Out Machine Options Plot Orientation: Vertical (Z-Up) Diameter Mode (Lathe) 22. 2) Milling Centre a. Side with 3" length is fixed parallel to axis (X) b. Side with 2" length is fixed parallel to axis (Y) c. Side with 1.5 length is fixed parallel to axis (Z) d. S=1500 (Spindle RPM) e. Tools : T1 (diameter is 0.1, radius is 0.05) unit: inch f. Z= 0 at the top surface of the wax block g. X=0 and Y=0 are located at the bottom left corner (All the dimensions are given in inch) Y+ (0,0,0) X + Raw Stock Specification: Milling Operation-Wax Piece: 3*2*1.5 inches Write a Milling NC program for the following design: Use the same design (123) and dimensions from homework 1. The depth of the letters is 0.3". 123 R.20 .10- - 11 R.30 R.20 .30 R.30 .30 123 240 .10+ .15 1.00 ,40 Y+ .30 X+ .30- N1 M06 T01; (Installing tool no .01) N2 G90; (absolute coordinate) N3 GOO XO YO Z0.5; ( rapid movement to X Y Z location) N4 S1500 M03; (Turn on spindle with 1500 rpm) N5 M8; (coolant supply on) N6 G00 X Y ; (Rapid movement to your X and Y coordinate) N7 G01 Z-0.3; (Tool goes 0.3" into the part) N? GOO Z0.5 (rapid movement to Z location) N? M05 (end of program) can 1) This is an individual assignment. You will need to use the CNC slides to complete this lab. Before you submit your program, you enter your code into https:/cviewer.com/ to check if it looks correct. Note: When you enter it into NC Viewer it should look something like the screenshot below. It does not have to look exactly like mine, you can start and stop from whatever positions you would like. TIL NC Viewer v1.1.3 Sample C GCode File S Digital Read Out Machine Options Plot Orientation: Vertical (Z-Up) Diameter Mode (Lathe) 22. 2) Milling Centre a. Side with 3" length is fixed parallel to axis (X) b. Side with 2" length is fixed parallel to axis (Y) c. Side with 1.5 length is fixed parallel to axis (Z) d. S=1500 (Spindle RPM) e. Tools : T1 (diameter is 0.1, radius is 0.05) unit: inch f. Z= 0 at the top surface of the wax block g. X=0 and Y=0 are located at the bottom left corner (All the dimensions are given in inch) Y+ (0,0,0) X + Raw Stock Specification: Milling Operation-Wax Piece: 3*2*1.5 inches Write a Milling NC program for the following design: Use the same design (123) and dimensions from homework 1. The depth of the letters is 0.3". 123 R.20 .10- - 11 R.30 R.20 .30 R.30 .30 123 240 .10+ .15 1.00 ,40 Y+ .30 X+ .30- N1 M06 T01; (Installing tool no .01) N2 G90; (absolute coordinate) N3 GOO XO YO Z0.5; ( rapid movement to X Y Z location) N4 S1500 M03; (Turn on spindle with 1500 rpm) N5 M8; (coolant supply on) N6 G00 X Y ; (Rapid movement to your X and Y coordinate) N7 G01 Z-0.3; (Tool goes 0.3" into the part) N? GOO Z0.5 (rapid movement to Z location) N? M05 (end of program)Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started