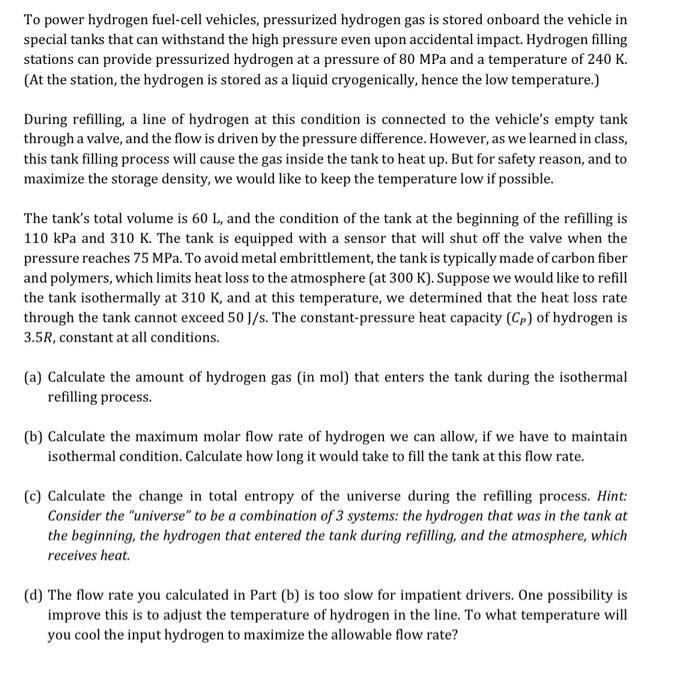

To power hydrogen fuel-cell vehicles, pressurized hydrogen gas is stored onboard the vehicle in special tanks that can withstand the high pressure even upon accidental impact. Hydrogen filling stations can provide pressurized hydrogen at a pressure of 80MPa and a temperature of 240K. (At the station, the hydrogen is stored as a liquid cryogenically, hence the low temperature.) During refilling, a line of hydrogen at this condition is connected to the vehicle's empty tank through a valve, and the flow is driven by the pressure difference. However, as we learned in class, this tank filling process will cause the gas inside the tank to heat up. But for safety reason, and to maximize the storage density, we would like to keep the temperature low if possible. The tank's total volume is 60L, and the condition of the tank at the beginning of the refilling is 110kPa and 310K. The tank is equipped with a sensor that will shut off the valve when the pressure reaches 75MPa. To avoid metal embrittlement, the tank is typically made of carbon fiber and polymers, which limits heat loss to the atmosphere (at 300K ). Suppose we would like to refill the tank isothermally at 310K, and at this temperature, we determined that the heat loss rate through the tank cannot exceed 50J/s. The constant-pressure heat capacity (CP) of hydrogen is 3.5R, constant at all conditions. (a) Calculate the amount of hydrogen gas (in mol) that enters the tank during the isothermal refilling process. (b) Calculate the maximum molar flow rate of hydrogen we can allow, if we have to maintain isothermal condition. Calculate how long it would take to fill the tank at this flow rate. (c) Calculate the change in total entropy of the universe during the refilling process. Hint: Consider the "universe" to be a combination of 3 systems: the hydrogen that was in the tank at the beginning, the hydrogen that entered the tank during refilling, and the atmosphere, which receives heat. (d) The flow rate you calculated in Part (b) is too slow for impatient drivers. One possibility is improve this is to adjust the temperature of hydrogen in the line. To what temperature will you cool the input hydrogen to maximize the allowable flow rate