Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Total quality management 1. The primary reason for adopting total quality management is to achieve a. Greater customer satisfaction. b. Reduced delivery time. c. Reduced

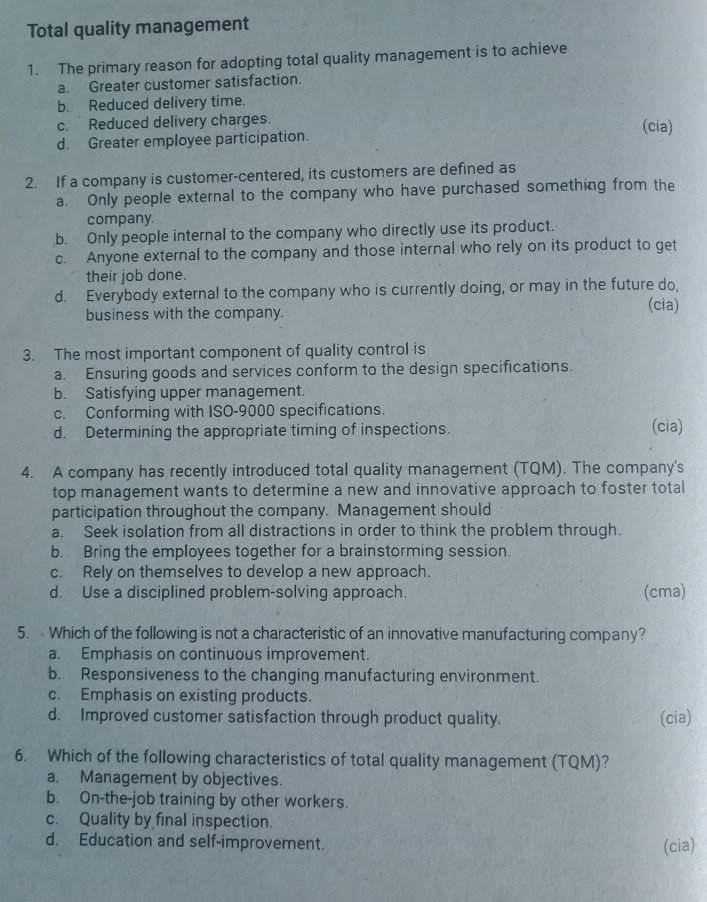

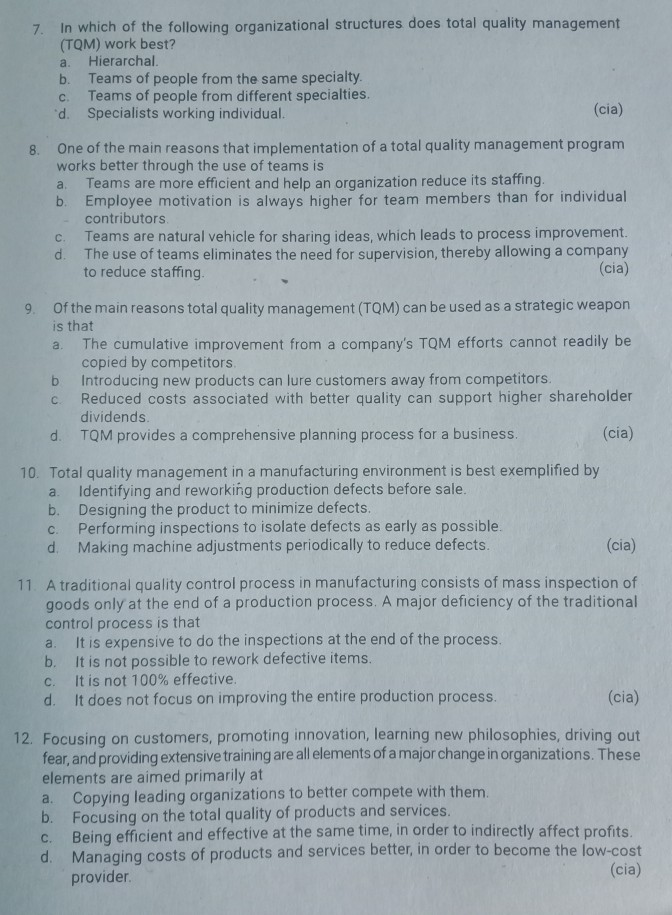

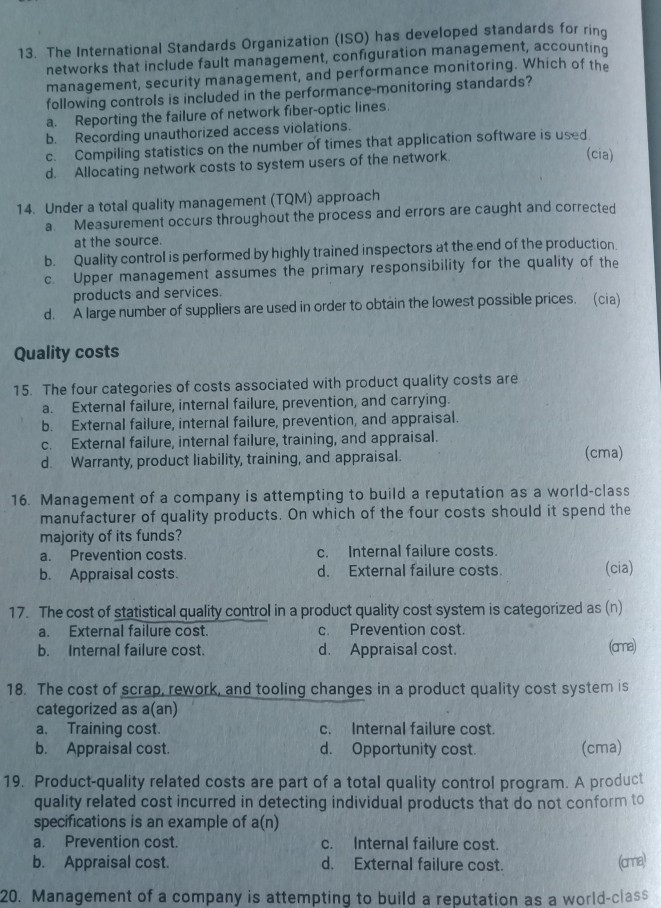

Total quality management 1. The primary reason for adopting total quality management is to achieve a. Greater customer satisfaction. b. Reduced delivery time. c. Reduced delivery charges. d. Greater employee participation (cia) 2. If a company is customer-centered, its customers are defined as a. Only people external to the company who have purchased something from the company b. Only people internal to the company who directly use its product. C. Anyone external to the company and those internal who rely on its product to get their job done. d. Everybody external to the company who is currently doing, or may in the future do, business with the company. (cia) 3. The most important component of quality control is a. Ensuring goods and services conform to the design specifications. b. Satisfying upper management. c. Conforming with ISO-9000 specifications. d. Determining the appropriate timing of inspections. (cia) 4. A company has recently introduced total quality management (TOM). The company's top management wants to determine a new and innovative approach to foster total participation throughout the company. Management should a. Seek isolation from all distractions in order to think the problem through. b. Bring the employees together for a brainstorming session. c. Rely on themselves to develop a new approach. d. Use a disciplined problem-solving approach. (cma) 5. Which of the following is not a characteristic of an innovative manufacturing company? a. Emphasis on continuous improvement. b. Responsiveness to the changing manufacturing environment. c. Emphasis on existing products. d. Improved customer satisfaction through product quality. (cia) 6. Which of the following characteristics of total quality management (TQM)? a. Management by objectives. b. On-the-job training by other workers. c. Quality by final inspection d. Education and self-improvement. (cia) 7. In which of the following organizational structures does total quality management (TQM) work best? a. Hierarchal. b. Teams of people from the same specialty c. Teams of people from different specialties. d. Specialists working individual. (cia) 8. One of the main reasons that implementation of a total quality management program works better through the use of teams is a. Teams are more efficient and help an organization reduce its staffing b. Employee motivation is always higher for team members than for individual - contributors C.Teams are natural vehicle for sharing ideas, which leads to process improvement. d. The use of teams eliminates the need for supervision, thereby allowing a company to reduce staffing (cia) Of the main reasons total quality management (TQM) can be used as a strategic weapon is that a. The cumulative improvement from a company's TQM efforts cannot readily be copied by competitors. b Introducing new products can lure customers away from competitors. c Reduced costs associated with better quality can support higher shareholder dividends. d. TOM provides a comprehensive planning process for a business. (cia) 10. Total quality management in a manufacturing environment is best exemplified by a. Identifying and reworking production defects before sale. b. Designing the product to minimize defects. C. Performing inspections to isolate defects as early as possible. d. Making machine adjustments periodically to reduce defects. (cia) 11. A traditional quality control process in manufacturing consists of mass inspection of goods only at the end of a production process. A major deficiency of the traditional control process is that a. It is expensive to do the inspections at the end of the process. b. It is not possible to rework defective items. C. It is not 100% effective. d. It does not focus on improving the entire production process. (cia) 12. Focusing on customers, promoting innovation, learning new philosophies, driving out fear, and providing extensive training are all elements of a major change in organizations. These elements are aimed primarily at a. Copying leading organizations to better compete with them b. Focusing on the total quality of products and services. C. Being efficient and effective at the same time, in order to indirectly affect profits. d. Managing costs of products and services better, in order to become the low-cost provider. (cia) 13. The International Standards Organization (ISO) has developed standards for Tine networks that include fault management, configuration management, accounting management, security management, and performance monitoring. Which of the following controls is included in the performance-monitoring standards? a. Reporting the failure of network fiber optic lines. b. Recording unauthorized access violations. c. Compiling statistics on the number of times that application software is used d. Allocating network costs to system users of the network (cia) 14. Under a total quality management (TQM) approach a. Measurement occurs throughout the process and errors are caught and corrected at the source b. Quality control is performed by highly trained inspectors at the end of the production c. Upper management assumes the primary responsibility for the quality of the products and services. d. A large number of suppliers are used in order to obtain the lowest possible prices. (cia) Quality costs 15. The four categories of costs associated with product quality costs are a. External failure, internal failure, prevention, and carrying b. External failure, internal failure, prevention, and appraisal. c. External failure, internal failure, training, and appraisal. d. Warranty, product liability, training, and appraisal. (cma) 16. Management of a company is attempting to build a reputation as a world-class manufacturer of quality products. On which of the four costs should it spend the majority of its funds? a. Prevention costs. c. Internal failure costs. b. Appraisal costs. d. External failure costs. (cia) 17. The cost of statistical quality control in a product quality cost system is categorized as (n) a. External failure cost. c. Prevention cost. b. Internal failure cost. d. Appraisal cost. (ara 18. The cost of scrap, rework, and tooling changes in a product quality cost system is categorized as a(an) a. Training cost. c. Internal failure cost. b. Appraisal cost. d. Opportunity cost. (cma) 19. Product-quality related costs are part of a total quality control program. A product quality related cost incurred in detecting individual products that do not conform to specifications is an example of a(n) a. Prevention cost. c. Internal failure cost. b. Appraisal cost d. External failure cost. 20. Management of a company is attempting to build a reputation as a world-class (arme

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started