Question

Truck Hauling Situation A truck hauling operation consists of one bulldozer, four trucks, and two machine loaders. Two piles of material must be stocked prior

Truck Hauling Situation

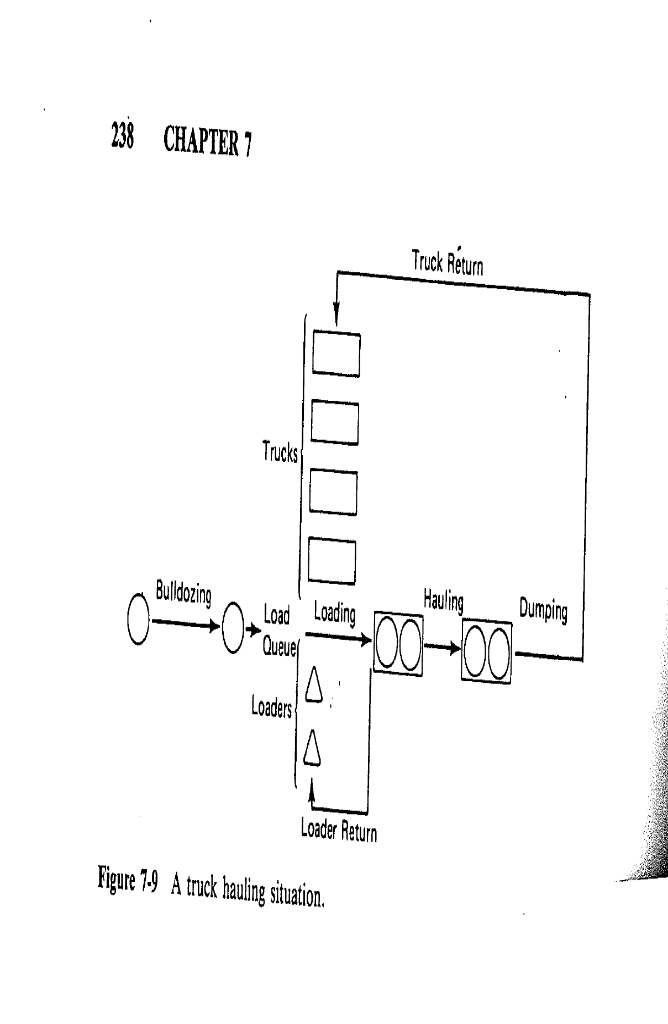

A truck hauling operation consists of one bulldozer, four trucks, and two machine loaders. Two piles of material must be stocked prior to the initiation of any load operation. The time for the bulldozer to stockpile material is Erlang distributed and consists of the sum of two exponential variables each with a mean of 4 (exponential mean 4, and Erlang parameter k = 2). In addition to this material, a loader must be available before the loading operation can begin. Loading time is exponentially distributed with a mean time of 14 minutes for server 1 and 12 minutes for server 2.

After a truck is loaded, it is hauled, then dumped and must be returned before the truck is available for further loading. Hauling time is normally distributed. When loaded, the average hauling time is 22 minutes. When unloaded, the average time is 18 minutes. In both cases, the standard deviation is 3 minutes. Dumping time is uniformly distributed between 2 and 8 minutes. Following a loading operation, the loader must rest for a 5 minute period before he is available to begin loading again. A schematic diagram of the system is shown below. Loaders take a lunch-break of half an hour 4 hours after their shift started. However, the lunch-break is taken by one loader at a time applying the following rule. When the lunch-break arrives, if only one loader is idle he starts with the lunch break, and is followed by the other loader. If both loaders are idle, loader one takes the lunch first due to seniority. If both loaders are busy, the loaders that end its loading cycle first, take the lunch first. Loaders do not preempt the loading process to take the lunch.

The truck hauling company works eight hours per day. You are the manager of the company and you want to analyze the operation of the system. Thus, you need to define which statistics need to be collected to analyze the performance of the system (defining the statistics will be considered in grading this question). Perform a terminating simulation analysis for this model. You must define and justify the number of replications required. Analyze the system as it is described, identify one or two significant parameters to improve the system, use PAN to compare 5 different scenarios by varying the parameters, and then evaluate the results in a statistically valid way to sort out which scenarios differ significantly from others.

Please use Arena to solve the question

238 CHAPTER 7 Truck Return ]O Trucks Bulldozing Hauling Dumping 07 Load Loading Queuel 00-00 10 Loaders Loader Return Figure 7-9 A truck hauling situation. 238 CHAPTER 7 Truck Return ]O Trucks Bulldozing Hauling Dumping 07 Load Loading Queuel 00-00 10 Loaders Loader Return Figure 7-9 A truck hauling situationStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started