Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Ultimate tensile strength [MPa] 3000 Q2. A close-coiled, extension helical spring is to be designed for a sophisticated instrument that requires high-precision and strength.

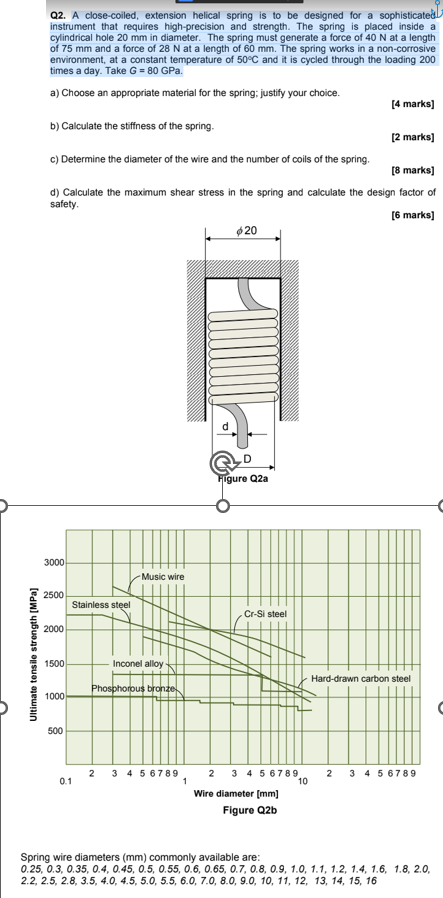

Ultimate tensile strength [MPa] 3000 Q2. A close-coiled, extension helical spring is to be designed for a sophisticated instrument that requires high-precision and strength. The spring is placed inside a cylindrical hole 20 mm in diameter. The spring must generate a force of 40 N at a length of 75 mm and a force of 28 N at a length of 60 mm. The spring works in a non-corrosive environment, at a constant temperature of 50C and it is cycled through the loading 200 times a day. Take G = 80 GPa. a) Choose an appropriate material for the spring: justify your choice. b) Calculate the stiffness of the spring. c) Determine the diameter of the wire and the number of coils of the spring. [4 marks] [2 marks] [8 marks] d) Calculate the maximum shear stress in the spring and calculate the design factor of safety. 2500 Stainless steel 2000 Music wire 1500 Inconel alloy- Phosphorous bronze 1000 500 $20 D Figure Q2a Cr-Si steel Hard-drawn carbon steel 10 2 34 3 4 5 6789 2 3 4 5 6789, 2 3456789 0.1 1 10 Wire diameter [mm] Figure Q2b Spring wire diameters (mm) commonly available are: 0.25, 0.3, 0.35, 0.4, 0.45, 0.5, 0.55, 0.6, 0.65, 0.7, 0.8, 0.9, 1.0, 1.1, 1.2, 1.4, 1.6, 1.8, 2.0, 2.2, 2.5, 2.8, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 7.0, 8.0, 9.0, 10, 11, 12, 13, 14, 15, 16 [6 marks] C

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started