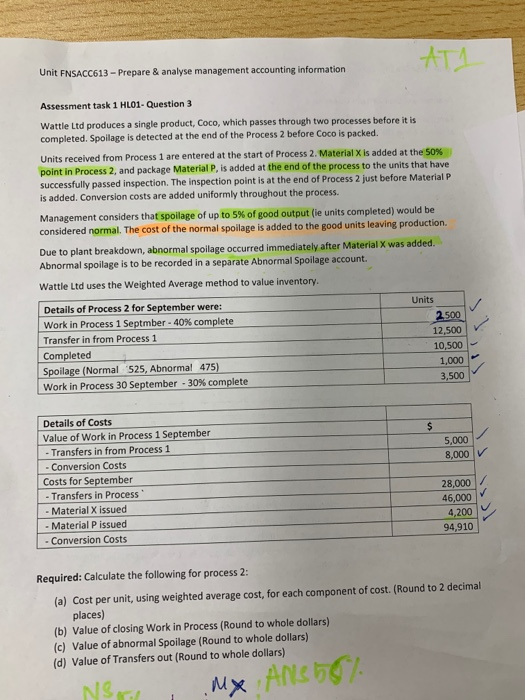

Unit FNSACC613 - Prepare & analyse management accounting information AT1 Assessment task 1 HL01 - Question 3 Wattie Ltd produces a single product, Coco, which passes through two processes before it is completed. Spoilage is detected at the end of the Process 2 before Coco is packed. Units received from Process 1 are entered at the start of Process 2. Material X is added at the 50% point in Process 2, and package Material P, is added at the end of the process to the units that have successfully passed inspection. The inspection point is at the end of Process 2 just before Material P is added. Conversion costs are added uniformly throughout the process. Management considers that spoilage of up to 5% of good output (le units completed) would be considered normal. The cost of the normal spoilage is added to the good units leaving production Due to plant breakdown, abnormal spoilage occurred immediately after Material x was added. Abnormal spoilage is to be recorded in a separate Abnormal Spoilage account. Wattle Ltd uses the Weighted Average method to value inventory. Details of Process 2 for September were: Units Work in Process 1 Septmber - 40% complete 2.500 Transfer in from Process 1 12.500 Completed Spoilage (Normal '525, Abnormal 475) 1.000 Work in Process 30 September - 30% complete 3,500 $ 5 ,000 8,000 V Details of Costs Value of Work in Process 1 September - Transfers in from Process 1 - Conversion Costs Costs for September - Transfers in Process: - Material X issued - Material P issued - Conversion Costs 28,000/ 46,000 4,200 94,910 Required: Calculate the following for process 2: (a) Cost per unit, using weighted average cost, for each component of cost. (Round to 2 decimal places) (b) Value of closing Work in Process (Round to whole dollars) Ic) Value of abnormal Spoilage (Round to whole dollars) (d) Value of Transfers out (Round to whole dollars) NS MX ANS 50% Unit FNSACC613 - Prepare & analyse management accounting information AT1 Assessment task 1 HL01 - Question 3 Wattie Ltd produces a single product, Coco, which passes through two processes before it is completed. Spoilage is detected at the end of the Process 2 before Coco is packed. Units received from Process 1 are entered at the start of Process 2. Material X is added at the 50% point in Process 2, and package Material P, is added at the end of the process to the units that have successfully passed inspection. The inspection point is at the end of Process 2 just before Material P is added. Conversion costs are added uniformly throughout the process. Management considers that spoilage of up to 5% of good output (le units completed) would be considered normal. The cost of the normal spoilage is added to the good units leaving production Due to plant breakdown, abnormal spoilage occurred immediately after Material x was added. Abnormal spoilage is to be recorded in a separate Abnormal Spoilage account. Wattle Ltd uses the Weighted Average method to value inventory. Details of Process 2 for September were: Units Work in Process 1 Septmber - 40% complete 2.500 Transfer in from Process 1 12.500 Completed Spoilage (Normal '525, Abnormal 475) 1.000 Work in Process 30 September - 30% complete 3,500 $ 5 ,000 8,000 V Details of Costs Value of Work in Process 1 September - Transfers in from Process 1 - Conversion Costs Costs for September - Transfers in Process: - Material X issued - Material P issued - Conversion Costs 28,000/ 46,000 4,200 94,910 Required: Calculate the following for process 2: (a) Cost per unit, using weighted average cost, for each component of cost. (Round to 2 decimal places) (b) Value of closing Work in Process (Round to whole dollars) Ic) Value of abnormal Spoilage (Round to whole dollars) (d) Value of Transfers out (Round to whole dollars) NS MX ANS 50%