URGENT and CLEARLY  PLEASE

PLEASE

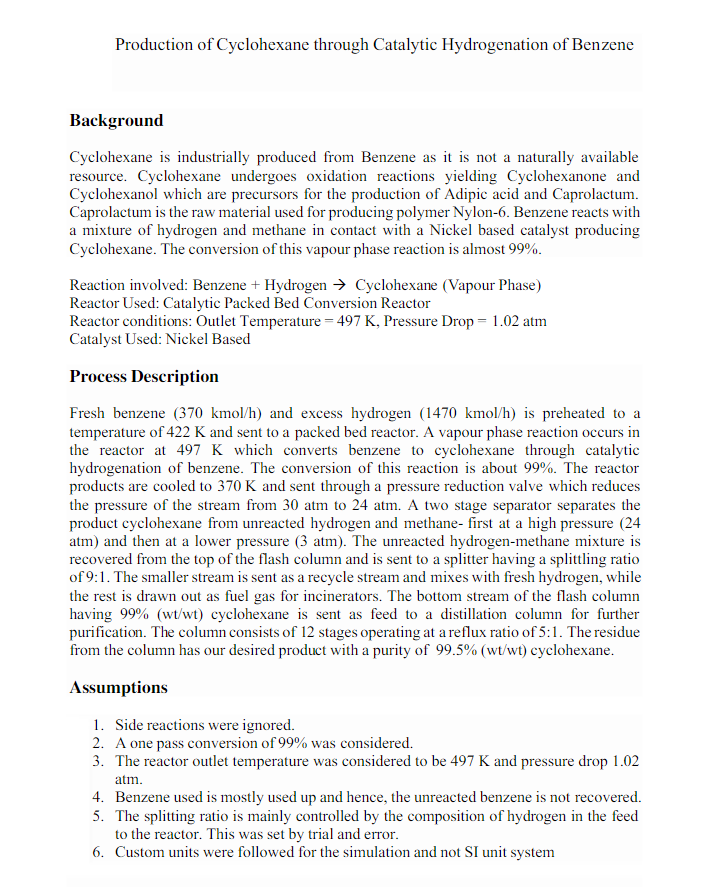

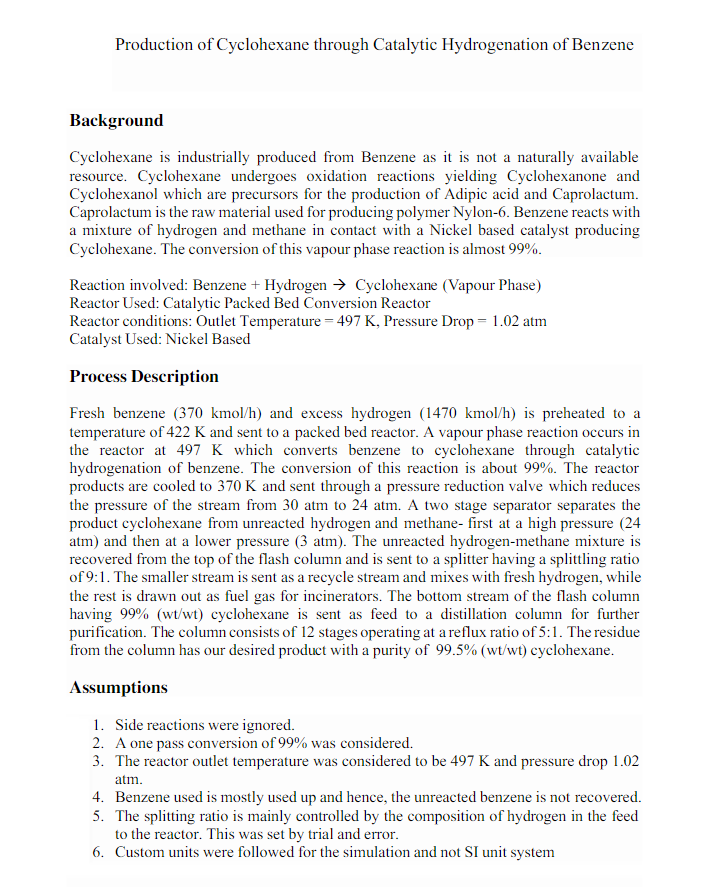

Production of Cyclohexane through Catalytic Hydrogenation of Benzene Background Cyclohexane is industrially produced from Benzene as it is not a naturally available resource. Cyclohexane undergoes oxidation reactions yielding Cyclohexanone and Cyclohexanol which are precursors for the production of Adipic acid and Caprolactum. Caprolactum is the raw material used for producing polymer Nylon-6. Benzene reacts with a mixture of hydrogen and methane in contact with a Nickel based catalyst producin Cyclohexane. The conversion of this vapour phase reaction is almost 99%. Reaction involved: Benzene + Hydrogen Cyclohexane (Vapour Phase) Reactor Used: Catalytic Packed Bed Conversion Reactor Reactor conditions: Outlet Temperature = 497 K, Pressure Drop = 1.02 atm Catalyst Used: Nickel Based Process Description Fresh benzene (370 kmol/h) and excess hydrogen (1470 kmol/h) is preheated to a temperature of 422 K and sent to a packed bed reactor. A vapour phase reaction occurs in the reactor at 497 K which converts benzene to cyclohexane through catalytic hydrogenation of benzene. The conversion of this reaction is about 99%. The reactor products are cooled to 370 K and sent through a pressure reduction valve which reduces the pressure of the stream from 30 atm to 24 atm. A two stage separator separates the product cyclohexane from unreacted hydrogen and methane- first at a high pressure (24 atm) and then at a lower pressure (3 atm). The unreacted hydrogen-methane mixture is recovered from the top of the flash column and is sent to a splitter having a splittling ratio of 9:1. The smaller stream is sent as a recycle stream and mixes with fresh hydrogen, while the rest is drawn out as fuel gas for incinerators. The bottom stream of the flash column having 99% (wt/wt) cyclohexane is sent as feed to a distillation column for further purification. The column consists of 12 stages operating at a reflux ratio of 5:1. The residue from the column has our desired product with a purity of 99.5% (wt/wt) cyclohexane. Assumptions 1. Side reactions were ignored. 2. A one pass conversion of 99% was considered. 3. The reactor outlet temperature was considered to be 497 K and pressure drop 1.02 atm. 4. Benzene used is mostly used up and hence, the unreacted benzene is not recovered. 5. The splitting ratio is mainly controlled by the composition of hydrogen in the feed to the reactor. This was set by trial and error. 6. Custom units were followed for the simulation and not SI unit system Production of Cyclohexane through Catalytic Hydrogenation of Benzene Background Cyclohexane is industrially produced from Benzene as it is not a naturally available resource. Cyclohexane undergoes oxidation reactions yielding Cyclohexanone and Cyclohexanol which are precursors for the production of Adipic acid and Caprolactum. Caprolactum is the raw material used for producing polymer Nylon-6. Benzene reacts with a mixture of hydrogen and methane in contact with a Nickel based catalyst producin Cyclohexane. The conversion of this vapour phase reaction is almost 99%. Reaction involved: Benzene + Hydrogen Cyclohexane (Vapour Phase) Reactor Used: Catalytic Packed Bed Conversion Reactor Reactor conditions: Outlet Temperature = 497 K, Pressure Drop = 1.02 atm Catalyst Used: Nickel Based Process Description Fresh benzene (370 kmol/h) and excess hydrogen (1470 kmol/h) is preheated to a temperature of 422 K and sent to a packed bed reactor. A vapour phase reaction occurs in the reactor at 497 K which converts benzene to cyclohexane through catalytic hydrogenation of benzene. The conversion of this reaction is about 99%. The reactor products are cooled to 370 K and sent through a pressure reduction valve which reduces the pressure of the stream from 30 atm to 24 atm. A two stage separator separates the product cyclohexane from unreacted hydrogen and methane- first at a high pressure (24 atm) and then at a lower pressure (3 atm). The unreacted hydrogen-methane mixture is recovered from the top of the flash column and is sent to a splitter having a splittling ratio of 9:1. The smaller stream is sent as a recycle stream and mixes with fresh hydrogen, while the rest is drawn out as fuel gas for incinerators. The bottom stream of the flash column having 99% (wt/wt) cyclohexane is sent as feed to a distillation column for further purification. The column consists of 12 stages operating at a reflux ratio of 5:1. The residue from the column has our desired product with a purity of 99.5% (wt/wt) cyclohexane. Assumptions 1. Side reactions were ignored. 2. A one pass conversion of 99% was considered. 3. The reactor outlet temperature was considered to be 497 K and pressure drop 1.02 atm. 4. Benzene used is mostly used up and hence, the unreacted benzene is not recovered. 5. The splitting ratio is mainly controlled by the composition of hydrogen in the feed to the reactor. This was set by trial and error. 6. Custom units were followed for the simulation and not SI unit system

PLEASE

PLEASE