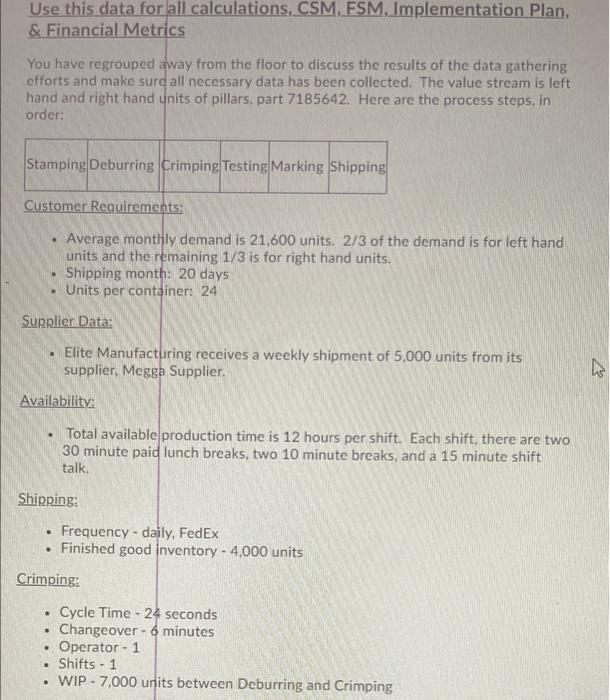

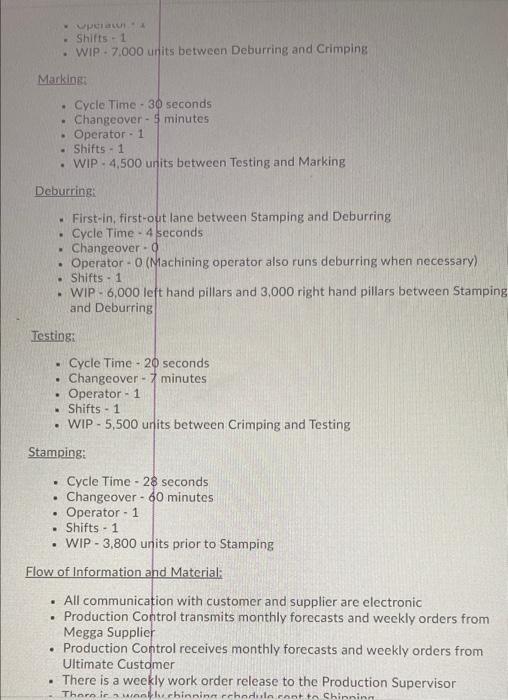

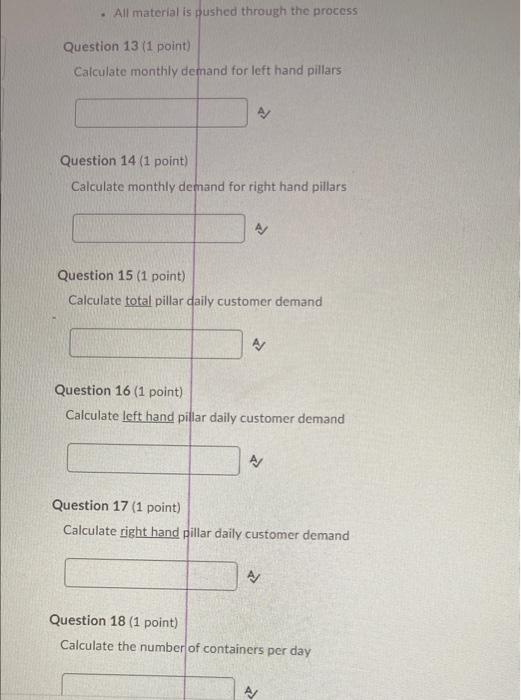

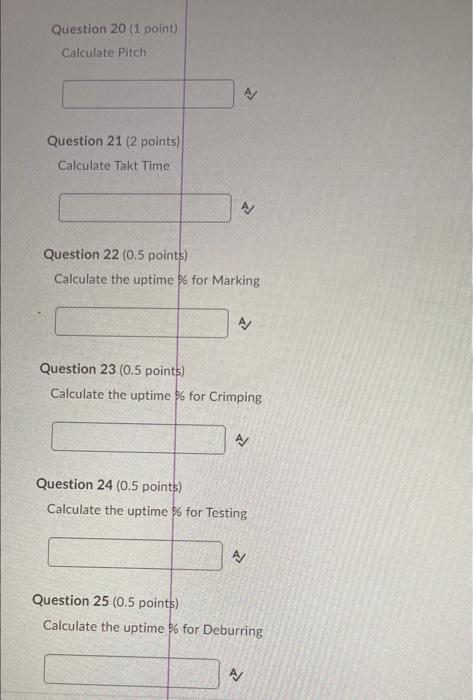

Use this data for all calculations. CSM, FSM, Implementation Plan, & Financial Metrics You have regrouped away from the floor to discuss the results of the data gathering efforts and make sure all necessary data has been collected. The value stream is left hand and right hand units of pillars, part 7185642. Here are the process steps, in order: Stamping Deburring Crimping Testing Marking Shipping Customer Requirements: Average monthly demand is 21,600 units. 2/3 of the demand is for left hand units and the remaining 1/3 is for right hand units. Shipping month: 20 days Units per container: 24 Supplier Data: ws x Elite Manufacturing receives a weekly shipment of 5,000 units from its supplier, Megga Supplier Availability: Total available production time is 12 hours per shift. Each shift, there are two 30 minute paid lunch breaks, two 10 minute breaks, and a 15 minute shift talk Shipping: . . Frequency - daily, FedEx Finished good Inventory - 4,000 units Crimping: . Cycle Time - 24 seconds Changeover - 6 minutes Operator - 1 Shifts - 1 WIP - 7,000 units between Deburring and Crimping . . Up Shifts -1 WIP - 7.000 units between Deburring and Crimping Marking: . Cycle Time - 30 seconds Changeover - 5 minutes Operator - 1 Shifts - 1 WIP.4,500 units between Testing and Marking Deburring: - First-in, first-out lane between Stamping and Deburring Cycle Time - 4 seconds Changeover. Operator - 0 (Machining operator also runs deburring when necessary) Shifts - 1 WIP - 6,000 left hand pillars and 3,000 right hand pillars between Stamping and Deburring Testing: Cycle Time - 20 seconds Changeover - 7 minutes Operator - 1 Shifts - 1 . WIP - 5,500 units between Crimping and Testing . Stamping: . . Cycle Time - 28 seconds Changeover - 60 minutes Operator - 1 Shifts - 1 WIP - 3,800 units prior to Stamping Flow of Information and Material: . All communication with customer and supplier are electronic Production Control transmits monthly forecasts and weekly orders from Megga Supplier Production Control receives monthly forecasts and weekly orders from Ultimate Customer There is a weekly work order release to the Production Supervisor Tharo ir merhinninn rchedule conta Chinninn . . . All material is pushed through the process Question 13(1 point) Calculate monthly demand for left hand pillars Question 14 (1 point) Calculate monthly demand for right hand pillars A Question 15 (1 point) Calculate total pillar daily customer demand A/ Question 16 (1 point) Calculate left hand pillar daily customer demand A Question 17 (1 point) Calculate right hand pillar daily customer demand A Question 18 (1 point) Calculate the number of containers per day Question 20 (1 point) Calculate Pitch A Question 21 (2 points) Calculate Takt Time N Question 22 (0.5 points) Calculate the uptime $6 for Marking Question 23 (0.5 points) Calculate the uptime for Crimping A Question 24 (0.5 points) Calculate the uptime % for Testing AJ Question 25 (0.5 points) Calculate the uptime for Deburring A/ Use this data for all calculations. CSM, FSM, Implementation Plan, & Financial Metrics You have regrouped away from the floor to discuss the results of the data gathering efforts and make sure all necessary data has been collected. The value stream is left hand and right hand units of pillars, part 7185642. Here are the process steps, in order: Stamping Deburring Crimping Testing Marking Shipping Customer Requirements: Average monthly demand is 21,600 units. 2/3 of the demand is for left hand units and the remaining 1/3 is for right hand units. Shipping month: 20 days Units per container: 24 Supplier Data: ws x Elite Manufacturing receives a weekly shipment of 5,000 units from its supplier, Megga Supplier Availability: Total available production time is 12 hours per shift. Each shift, there are two 30 minute paid lunch breaks, two 10 minute breaks, and a 15 minute shift talk Shipping: . . Frequency - daily, FedEx Finished good Inventory - 4,000 units Crimping: . Cycle Time - 24 seconds Changeover - 6 minutes Operator - 1 Shifts - 1 WIP - 7,000 units between Deburring and Crimping . . Up Shifts -1 WIP - 7.000 units between Deburring and Crimping Marking: . Cycle Time - 30 seconds Changeover - 5 minutes Operator - 1 Shifts - 1 WIP.4,500 units between Testing and Marking Deburring: - First-in, first-out lane between Stamping and Deburring Cycle Time - 4 seconds Changeover. Operator - 0 (Machining operator also runs deburring when necessary) Shifts - 1 WIP - 6,000 left hand pillars and 3,000 right hand pillars between Stamping and Deburring Testing: Cycle Time - 20 seconds Changeover - 7 minutes Operator - 1 Shifts - 1 . WIP - 5,500 units between Crimping and Testing . Stamping: . . Cycle Time - 28 seconds Changeover - 60 minutes Operator - 1 Shifts - 1 WIP - 3,800 units prior to Stamping Flow of Information and Material: . All communication with customer and supplier are electronic Production Control transmits monthly forecasts and weekly orders from Megga Supplier Production Control receives monthly forecasts and weekly orders from Ultimate Customer There is a weekly work order release to the Production Supervisor Tharo ir merhinninn rchedule conta Chinninn . . . All material is pushed through the process Question 13(1 point) Calculate monthly demand for left hand pillars Question 14 (1 point) Calculate monthly demand for right hand pillars A Question 15 (1 point) Calculate total pillar daily customer demand A/ Question 16 (1 point) Calculate left hand pillar daily customer demand A Question 17 (1 point) Calculate right hand pillar daily customer demand A Question 18 (1 point) Calculate the number of containers per day Question 20 (1 point) Calculate Pitch A Question 21 (2 points) Calculate Takt Time N Question 22 (0.5 points) Calculate the uptime $6 for Marking Question 23 (0.5 points) Calculate the uptime for Crimping A Question 24 (0.5 points) Calculate the uptime % for Testing AJ Question 25 (0.5 points) Calculate the uptime for Deburring A/