Question

For the phase diagram below: The Vickers Hardness measurments of 3 different plain carbon steal samples are shown in the table below A) 0.25C (Air

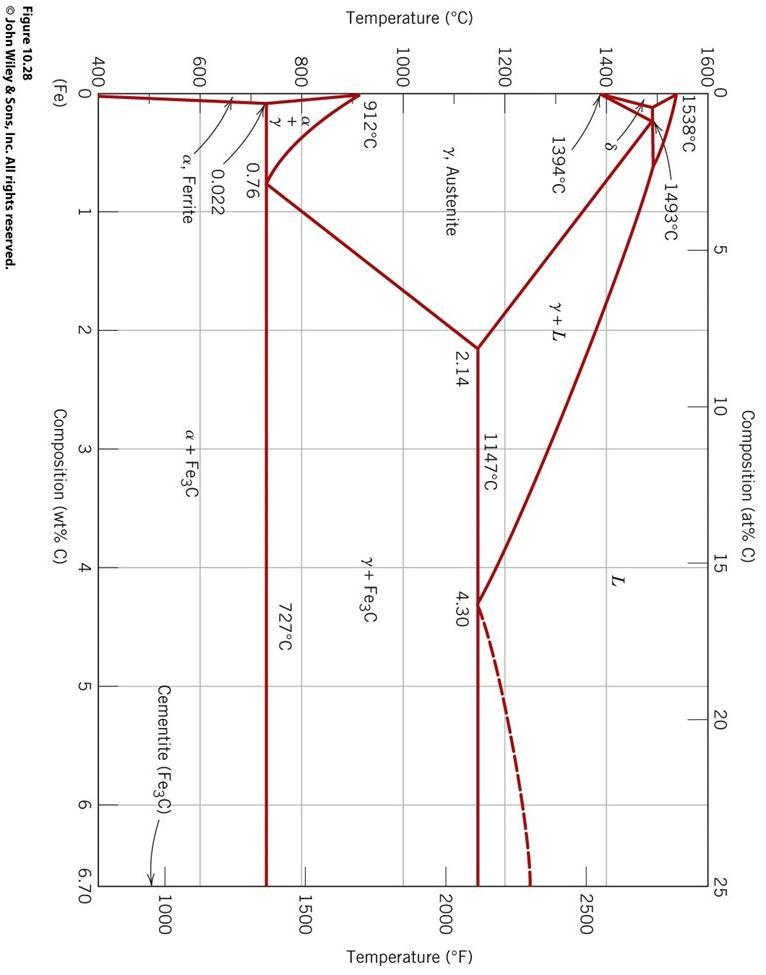

For the phase diagram below:

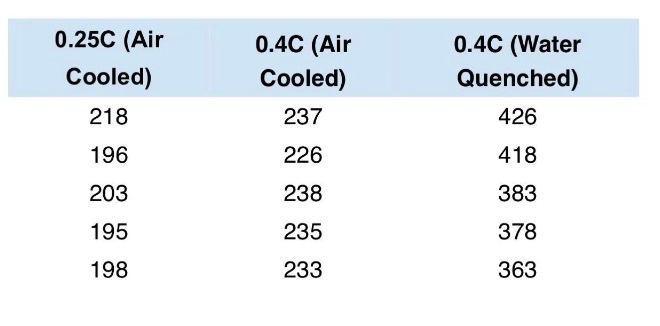

The Vickers Hardness measurments of 3 different plain carbon steal samples are shown in the table below

A) 0.25C (Air Cooled): Plain carbon steel with a low carbon content of 0.25 wt% that has been heated to ~ 950°C and cooled slowly in air

B) 0.4C (Air Cooled): Plain carbon steel with a higher carbon content of 0.4 wt% that has been heated to ~ 950°C and cooled slowly in air

C) 0.4C (Water Quenched) Plain carbon steel with a carbon content of 0.4 wt% that has been heated to 950°C and quenched in water.

Q6: For sample C (0.4C Water Quenched) , explain the difference in the hardness in terms of the difference in the relative amounts of the phases present in the microstructure.

- explain in terms of the microstructure why the hardness is higher than for the sample with the same carbon content that was cooled in air (Sample B).

- identify the mechanical property of steel that may be adversely affected by quenching.

Temperature (C) 0 1600 1400 1200 1000 800 600 400 1538C 0 (Fe) 912C + Y -1493C 1394C y, Austenite 0.76 0.022 a, Ferrite 5 Figure 10.28 John Wiley & Sons, Inc. All rights reserved. Y+L 2 2.14 Composition (at% C) 15 10 1147C a + Fe3C L 3 4 Composition (wt% C) 4.30 y+ Fe3C 727C 20 Cementite (Fe3C) 5 6 25 2500 2000 1500 1000 6.70 Temperature (F)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Answer Ans 5 Normalizing is the process of heating 04 C steel to 950oC and then letting it cool slowly in air We normalize steel to make the grains sm...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started