Answered step by step

Verified Expert Solution

Question

1 Approved Answer

using the program arena 15.0, please solve 1. [25] You have been asked to model a widget factory. There are three types of widgets that

using the program arena 15.0, please solve

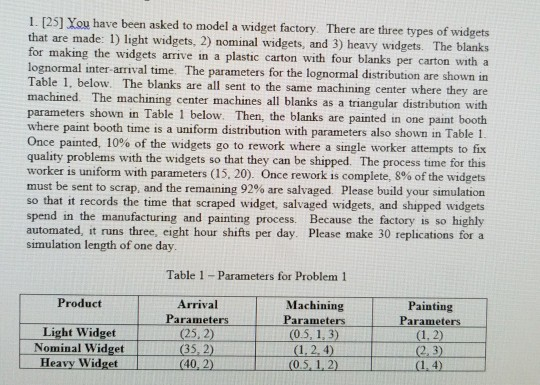

1. [25] You have been asked to model a widget factory. There are three types of widgets that are made: 1) light widgets, 2) nominal widgets, and 3) heavy widgets. The blanks for making the widgets arrive in a plastic carton with four b lognormal inter -arrival time. The parameters for the lognormal distribution are shown in Table 1, below. The blanks are all sent to the same machining center where they are machined. The machining center machines all blanks as a triangular distribution with parameters shown in Table 1 below. Then, the blanks are painted in one paint booth where paint booth time is a uniform distribution with parameters also sh Once painted, 10% of the widgets go to rework where a single worker attempts to fix quality problems with the widgets so that they can be shipped. The process time for this worker is uniform with parameters (15, 20). Once rework is complete, goo of the widgets must be sent to scrap, and the remaining 92% are salvaged, please build your simulation so that it records the time that scraped widget, salvaged widgets, and shipped widgets spend in the manufacturing and painting process. Because the factory is so highly automated, it runs three, eight hour shifts per day. Please make 30 replications for a simulation length of one day lanks per carton witha Table 1 -Parameters for Problem 1 Product Arrival Parameters (25,2) (35, 2) (40, 2) Painting Parameters 1, 2) (2,3) Machining Parameters Light Widget Nominal Widget Heavy Widget (0.5, 1 2 1. [25] You have been asked to model a widget factory. There are three types of widgets that are made: 1) light widgets, 2) nominal widgets, and 3) heavy widgets. The blanks for making the widgets arrive in a plastic carton with four b lognormal inter -arrival time. The parameters for the lognormal distribution are shown in Table 1, below. The blanks are all sent to the same machining center where they are machined. The machining center machines all blanks as a triangular distribution with parameters shown in Table 1 below. Then, the blanks are painted in one paint booth where paint booth time is a uniform distribution with parameters also sh Once painted, 10% of the widgets go to rework where a single worker attempts to fix quality problems with the widgets so that they can be shipped. The process time for this worker is uniform with parameters (15, 20). Once rework is complete, goo of the widgets must be sent to scrap, and the remaining 92% are salvaged, please build your simulation so that it records the time that scraped widget, salvaged widgets, and shipped widgets spend in the manufacturing and painting process. Because the factory is so highly automated, it runs three, eight hour shifts per day. Please make 30 replications for a simulation length of one day lanks per carton witha Table 1 -Parameters for Problem 1 Product Arrival Parameters (25,2) (35, 2) (40, 2) Painting Parameters 1, 2) (2,3) Machining Parameters Light Widget Nominal Widget Heavy Widget (0.5, 1 2Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started