Question: Various uses for nitric acid are given in Problem 6.43, along with information about how this important chemical is synthesized industrially. The key reactions

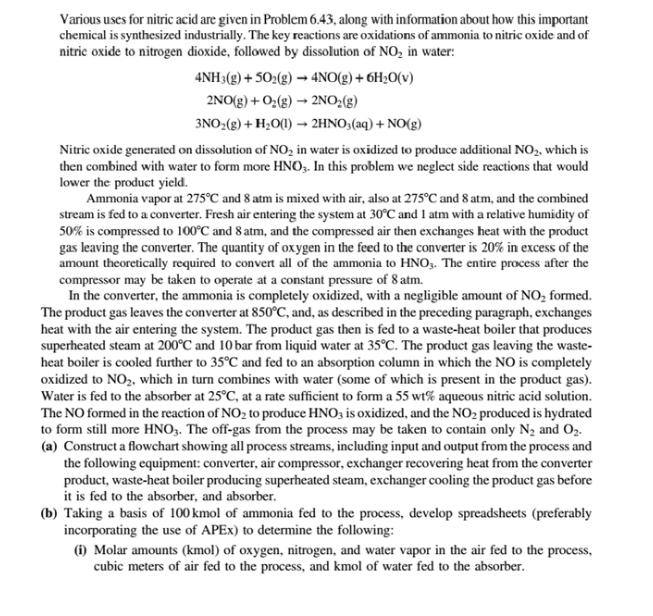

Various uses for nitric acid are given in Problem 6.43, along with information about how this important chemical is synthesized industrially. The key reactions are oxidations of ammonia to nitric oxide and of nitric oxide to nitrogen dioxide, followed by issolution of NO, in water: 4NH3(g) + 50:(g) - 4NO(g) + 6H20(v) 2NO(g) +0:(g) - 2NO;(g) 3NO:(g) + H,O(1) 2HNO,(aq) + NO(g) Nitric oxide generated on dissolution of NO, in water is oxidized to produce additional NO, which is then combined with water to form more HNO,. In this problem we neglect side reactions that would lower the product yield. Ammonia vapor at 275C and 8 atm is mixed with air, also at 275C and 8 atm, and the combined stream is fed to a converter. Fresh air entering the system at 30C and I atm with a relative humidity of 50% is compressed to 100C and 8 atm, and the compressed air then exchanges heat with the product gas leaving the converter. The quantity of oxygen in the feed to the converter is 20% in excess of the amount theoretically required to convert all of the ammonia to HNO,. The entire process after the compressor may be taken to operate at a constant pressure of 8 atm. In the converter, the ammonia is completely oxidized, with a negligible amount of NO, formed. The product gas leaves the converter at 850C, and, as described in the preceding paragraph, exchanges heat with the air entering the system. The product gas then is fed to a waste-heat boiler that produces superheated steam at 200C and 10 bar from liquid water at 35C. The product gas leaving the waste- heat boiler is cooled further to 35C and fed to an absorption column in which the NO is completely oxidized to NO,, which in turn combines with water (some of which is present in the product gas). Water is fed to the absorber at 25C, at a rate sufficient to form a 55 wt% aqueous nitric acid solution. The NO formed in the reaction of NO2 to produce HNO, is oxidized, and the NO2 produced is hydrated to form still more HNO3. The off-gas from the process may be taken to contain only N2 and O2. (a) Construct a flowchart showing all process streams, including input and output from the process and the following equipment: converter, air compressor, exchanger recovering heat from the converter product, waste-heat boiler producing superheated steam, exchanger cooling the product gas before it is fed to the absorber, and absorber. (b) Taking a basis of 100 kmol of ammonia fed to the process, develop spreadsheets (preferably incorporating the use of APEX) to determine the following: (1) Molar amounts (kmol) of oxygen, nitrogen, and water vapor in the air fed to the process, cubic meters of air fed to the process, and kmol of water fed to the absorber. (ii) Molar amounts, molar composition, and volume of the off-gas leaving the absorber. (iii) Mass (kg) of product nitric acid solution. (iv) Molar amounts and composition of the gas leaving the converter. (v) Heat removed from or added to (state which) the converter. (vi) Temperature of the product gas after it has exchanged heat with the air, assuming no heat is transferred between the heat exchanger and the surroundings. (vii) Production rate of superheated steam if the gas temperature leaving the boiler is 205C. Before performing this calculation, determine if condensation of water occurs when the gas is cooled to 205C. Since the superheated steam temperature is 200C, explain why the selected temperature of the product gas is reasonable. (viii) Heat removed from the product gas before it is fed to the absorber (Hint: Check the condition of the gas at 35C) and mass of cooling water required to remove that heat if the water temperature can only be increased by 5C. Assume no heat is transferred between the heat exchanger and the surroundings. (ix) Heat removed from or added to the absorber. Assume the heat capacity of the nitric acid solution is approximately the same as that of liquid water and the outlet temperatures of the off-gas and product streams are 25C and 35C, respectively.

Step by Step Solution

3.37 Rating (166 Votes )

There are 3 Steps involved in it

To solve this problem follow these steps to analyze and calculate each requirement given the context of the industrial production of nitric acid 1 Ove... View full answer

Get step-by-step solutions from verified subject matter experts